Method for preparing spiral carbon nano pipe

A carbon nanotube and helical technology, which is applied in the field of preparing helical carbon nanotubes, can solve the problems that cannot meet the research and application fields, and achieves the effects of low cost, simple processing technology and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] After the manganese nodule minerals from the seabed are roughly crushed, they are ultrasonically cleaned in a large amount of clean water to remove dirt such as clay attached to the surface. Then ball mill and sieve the powder below 200 mesh to be used as catalyst.

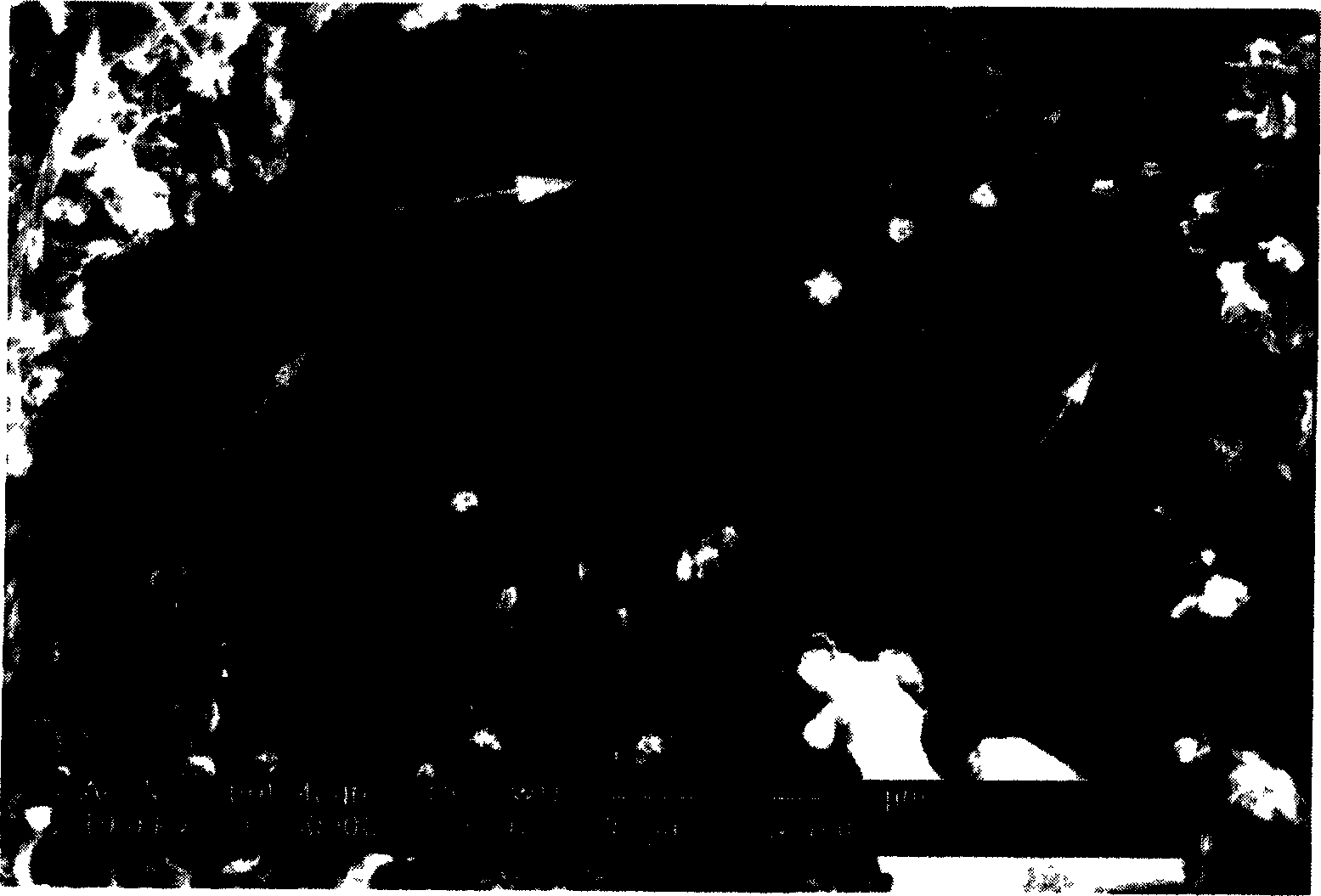

[0016] Put the above-mentioned mineral catalyst into a quartz boat of a chemical vapor deposition device, heat to 750° C., and keep it warm for 20 minutes under a nitrogen atmosphere. Then feed acetylene gas at 80ml / min, catalyze the cracking reaction for 15 minutes, and obtain a product containing a large number of helical carbon nanotubes, the scanning electron microscope photo of which is shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com