Temperature controller of small semiconductor laser

A temperature control device and semiconductor technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of complex circuit structure, high development cost, and difficulty in adjusting the stable working temperature, and achieve the effect of adjustable temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereto.

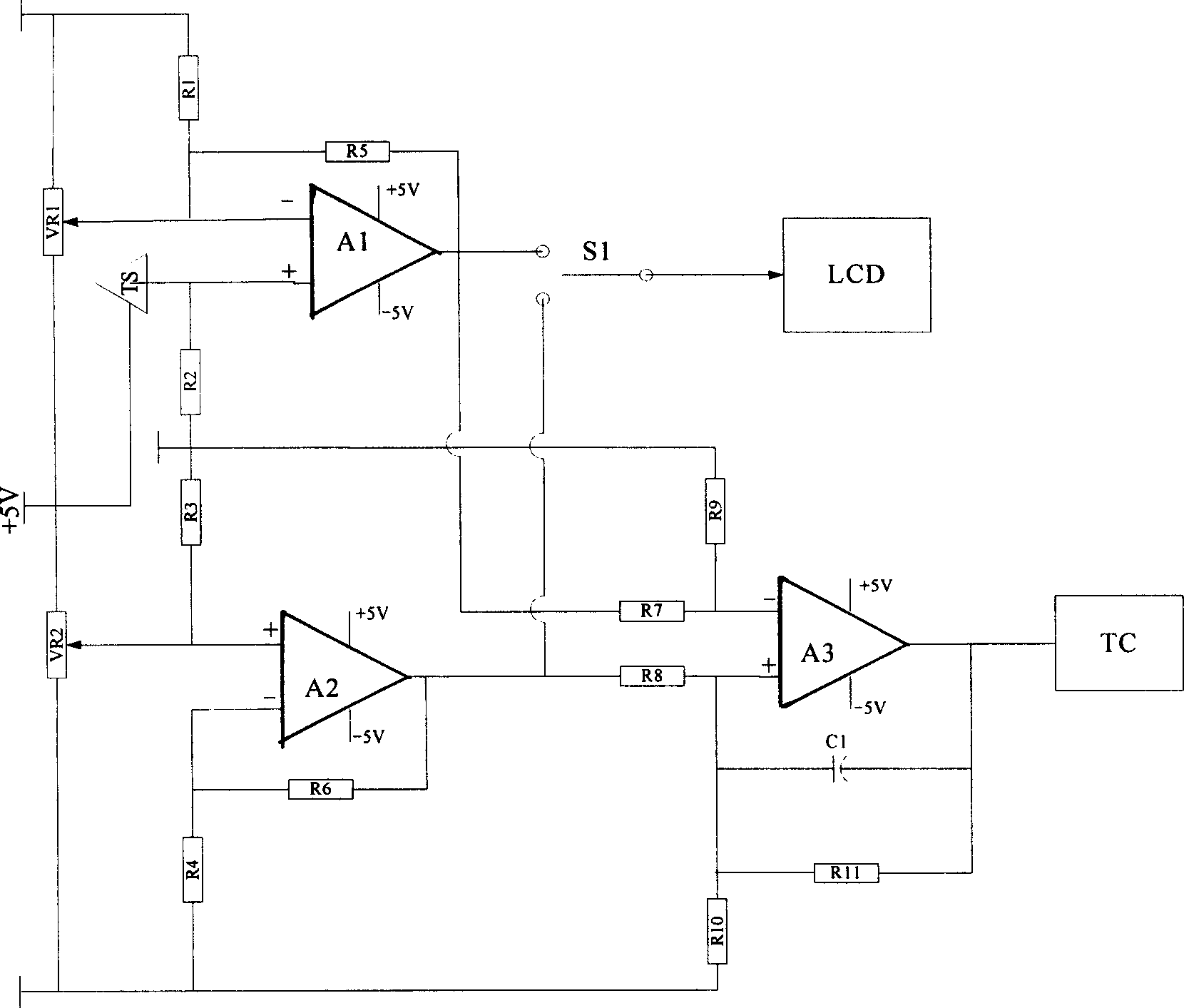

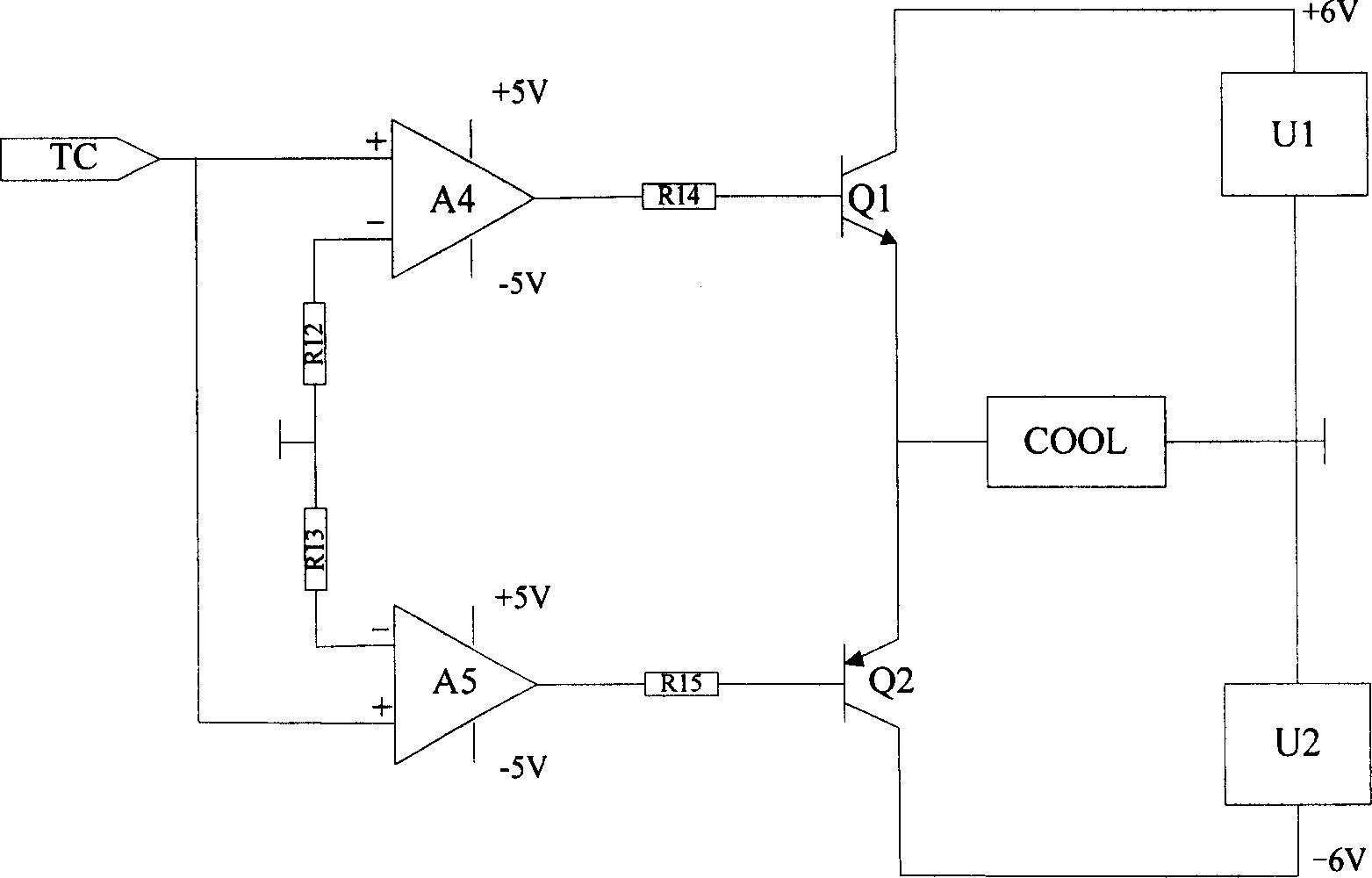

[0015] see first figure 1 , figure 1 It is a schematic diagram of the circuit structure of the small-scale semiconductor laser temperature control device of the present invention. It can be seen from the figure that the small-scale semiconductor laser temperature control device of the present invention is mainly composed of a laser working temperature sampling part, a reference temperature setting part, a temperature comparison control output part and a laser working temperature adjustment part. Partial composition.

[0016] figure 1 Among them, the negative input terminal of the operational amplifier A1 is respectively connected to one terminal of the resistors R1 and R5 and the sliding terminal of the rheostat VR1. The other end of the resistor R1 is connected to the zero potential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com