Triple sleeving thermal siphon pumps

A thermosiphon and ring sleeve technology, applied in the direction of siphon pipes, pump components, adsorption machines, etc., can solve the problems that restrict the commercial application of diffusion refrigeration systems, high riser height, poor system performance, etc., and achieve favorable heat Transfer, reduce the amount of metal used, improve the effect of heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

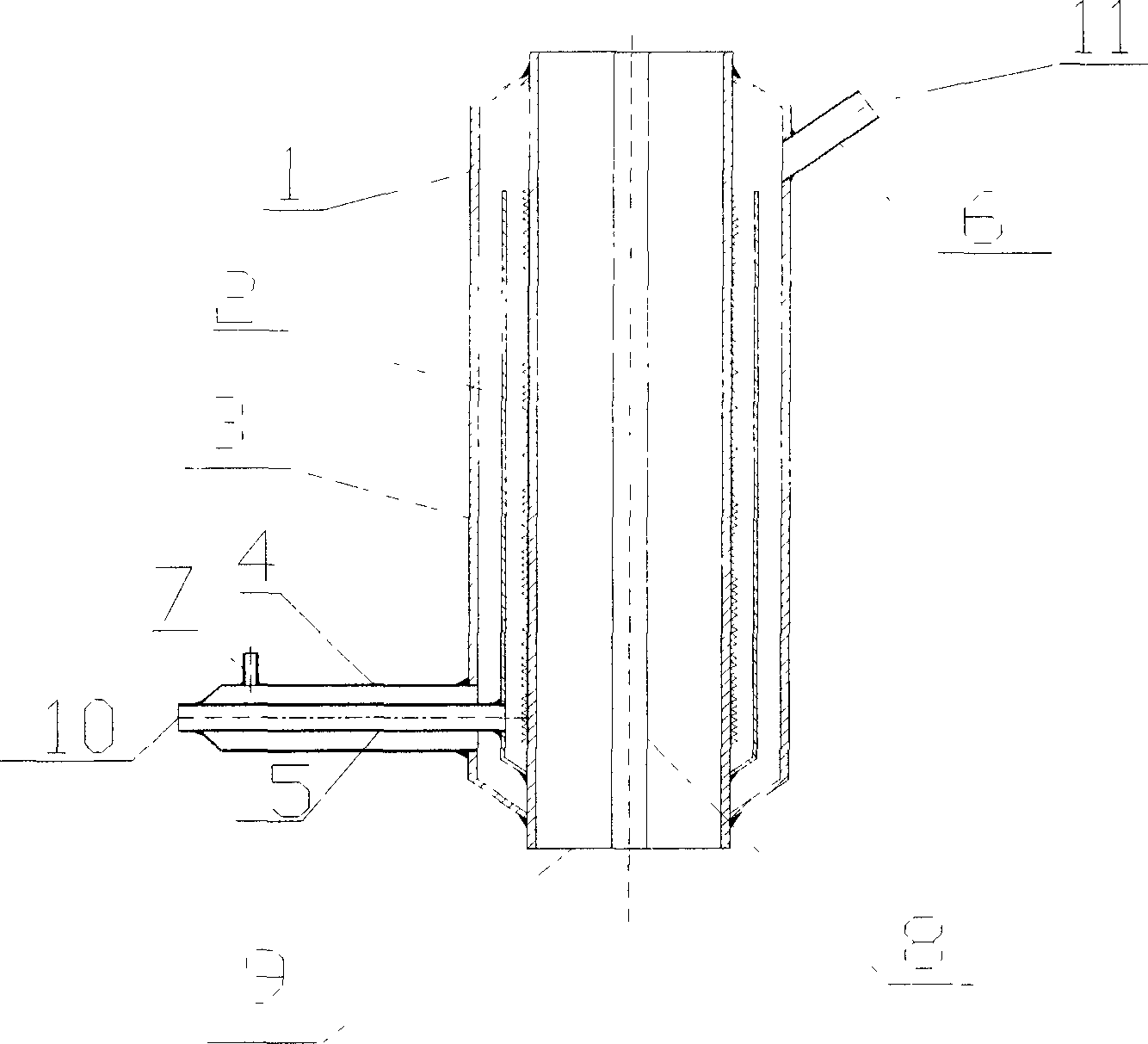

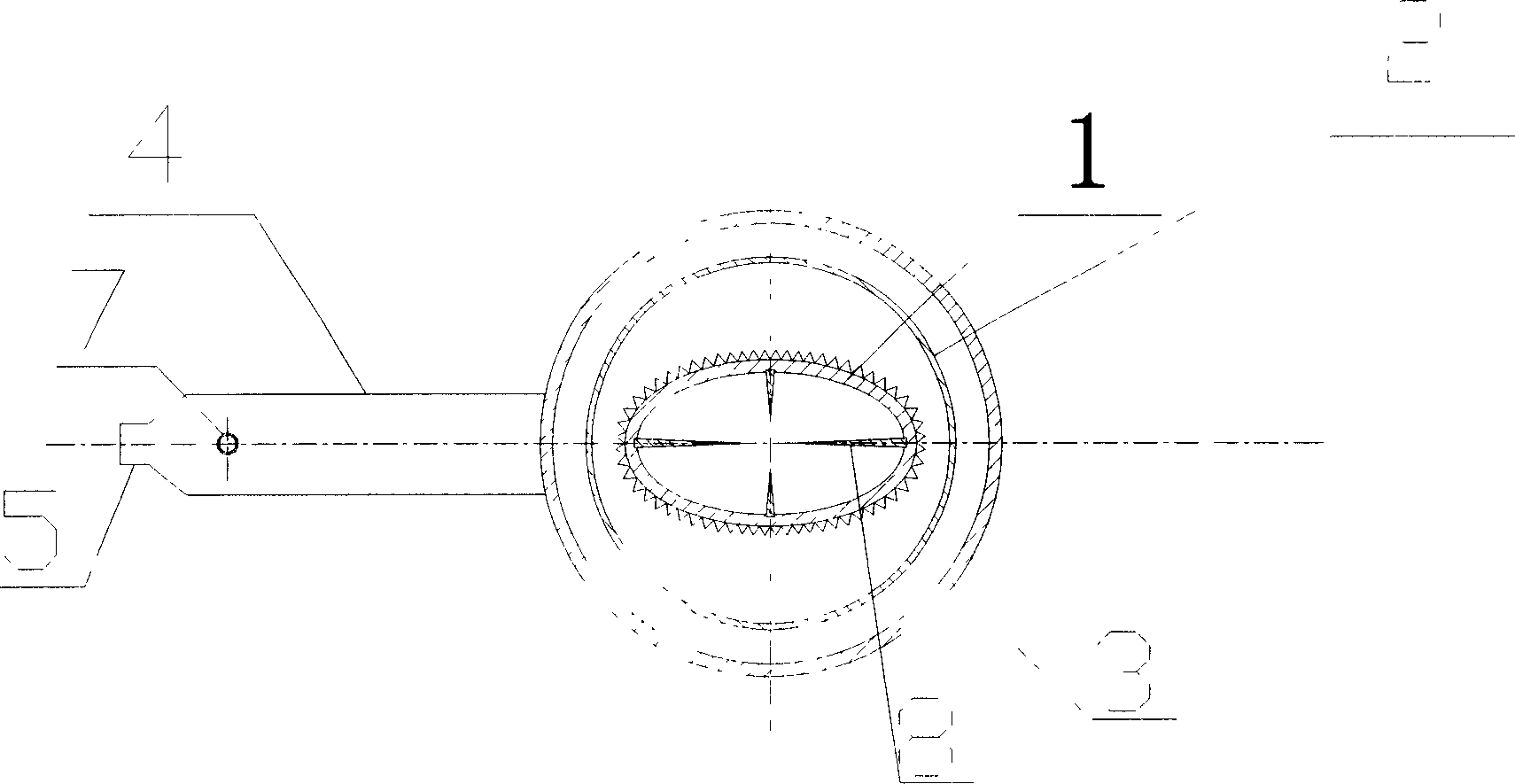

[0022] A schematic diagram of the structure of the present invention is attached figure 1 As shown, based on the elliptical seamless inner tube 1, first, the outer middle section of the seamless inner tube 1 is processed into a porous tube, and a certain number of fin grooves are processed on the inner side of the seamless inner tube 1, and then the inner tube 1 is processed. A dividing pipe 2 is welded outside, the lower end of the dividing pipe 2 is welded with the inner pipe 1, the upper end is open, and a concentrated solution feeding pipe 5 is welded at the lower end; the outer pipe 3 is welded on the outside of the dividing pipe, and the upper and lower ends of the outer pipe 3 are connected by connecting pipes. , wherein the dilute solution lead-out pipe 4 is welded below, the solute vapor or refrigerant gas outlet pipe 6 is welded on the top, and the dilute sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com