Large pneumatic equipment blades made of composite material and production thereof

A technology of wind turbine blades and composite materials, which is applied in the directions of wind turbines, wind turbine components, mechanical equipment, etc., can solve the problems of increasing the expenditure of special equipment and increasing the cost of blade manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

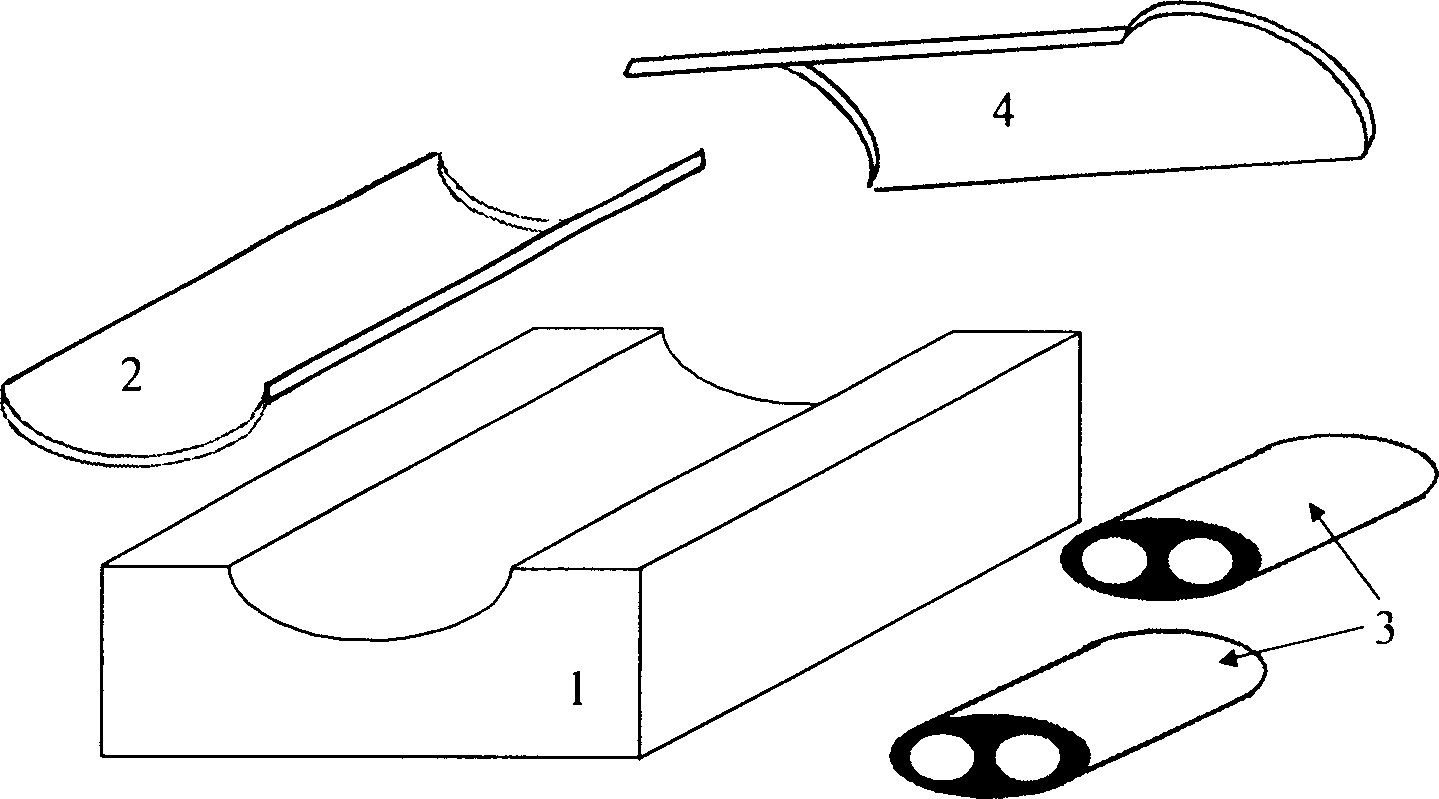

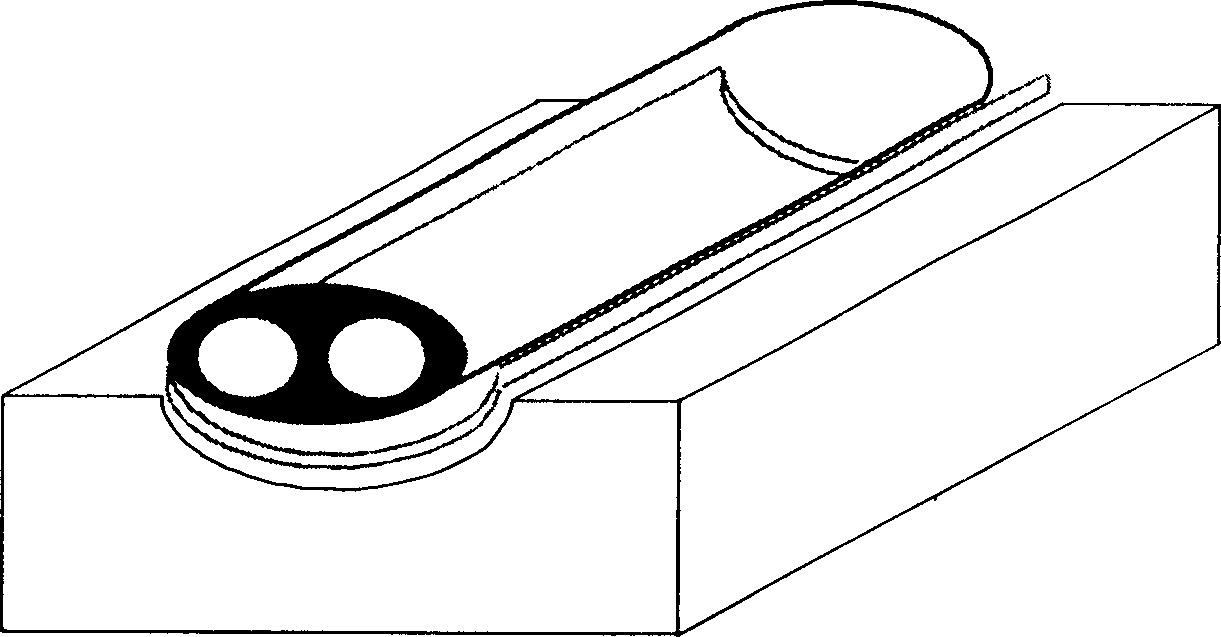

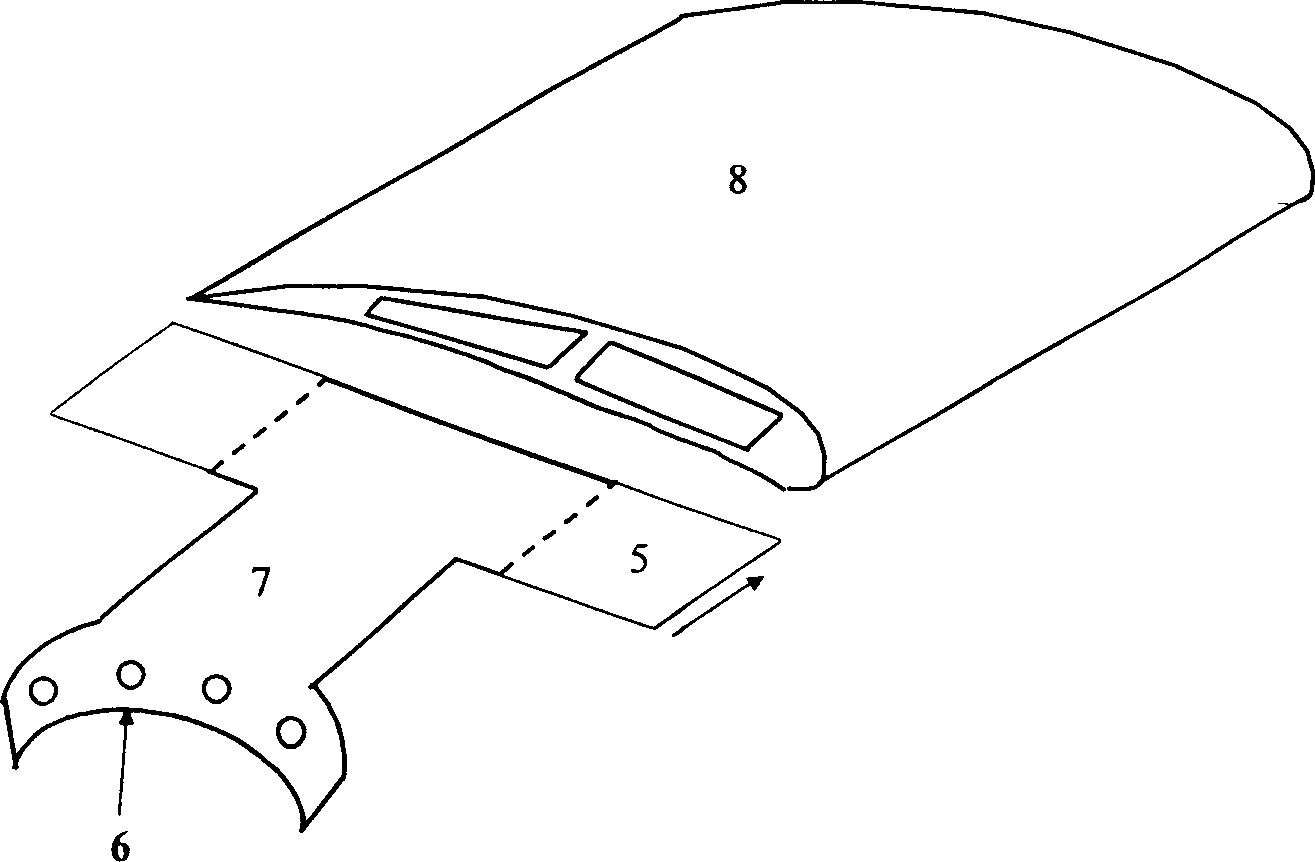

[0030] The metal (aluminum alloy, titanium alloy, stainless steel, etc.) connector 7 passes through the solid wooden keel frame 5, wherein the cross-sectional shape of the metal passing section is square, and is fastened with gaskets and nuts at the other end of the keel frame, see hint image 3 , the shape of the keel frame is consistent with the cross-sectional shape of the blade root. The length of the solid keel frame (the direction indicated by the arrow) is limited, no more than 0.5m. All the other sections of the keel frames 8 are hollow wooden structures, made of wooden splints and battens, and have an appropriate length. After all these keel frames are connected end to end, the similar shape of the blade to be prepared must be formed. The laying of the fiber cloth in the lower cavity 1 is shown in the cross section Figure 5 : Pre-impregnated (medium temperature curing resin, curing temperature 60°-100°) multi-layer carbon fiber woven cloth 9, braiding angle 10°-20...

Embodiment 2

[0032] Embodiment 2 is basically the same as Embodiment 1, but each fiber cloth (i.e. carbon fiber cloth 9, glass fiber cloth 11, nylon cloth 12) is no longer divided into two pieces (see schematic diagram Figure 5 10) in , but weave into schematic Figure 6 Cylindrical shape shown in 13. The leaves were prepared in the same manner as described in Example 1.

Embodiment 3

[0034] Embodiment 3 is basically the same as Embodiment 1, but some inner layer fiber cloths are pressed Figure 7 As shown in the preparation, wherein 14 is a carbon fiber cloth, 15 is a nylon cloth, which are sewn together into one. The use of this composite fiber cloth is convenient to realize the change of the thickness of the blade shell along the section circumference as required. Due to the airfoil shape of the blade section, the force-bearing area is on the windward side, while the force on the other side sheltered from the wind is relatively small. Therefore, the optimally designed composite blades not only have different cross-sectional shapes, but also have different shell thicknesses in the same cross-section: thicker on the windward side and thinner on the sheltered side. application Figure 7 As shown in the fiber cloth, the purpose can be achieved by arranging the nylon cloth on the sheltered side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com