Polishing machine

A polishing machine and tool holder technology, applied in the polishing machine field, can solve the problems of low work reliability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

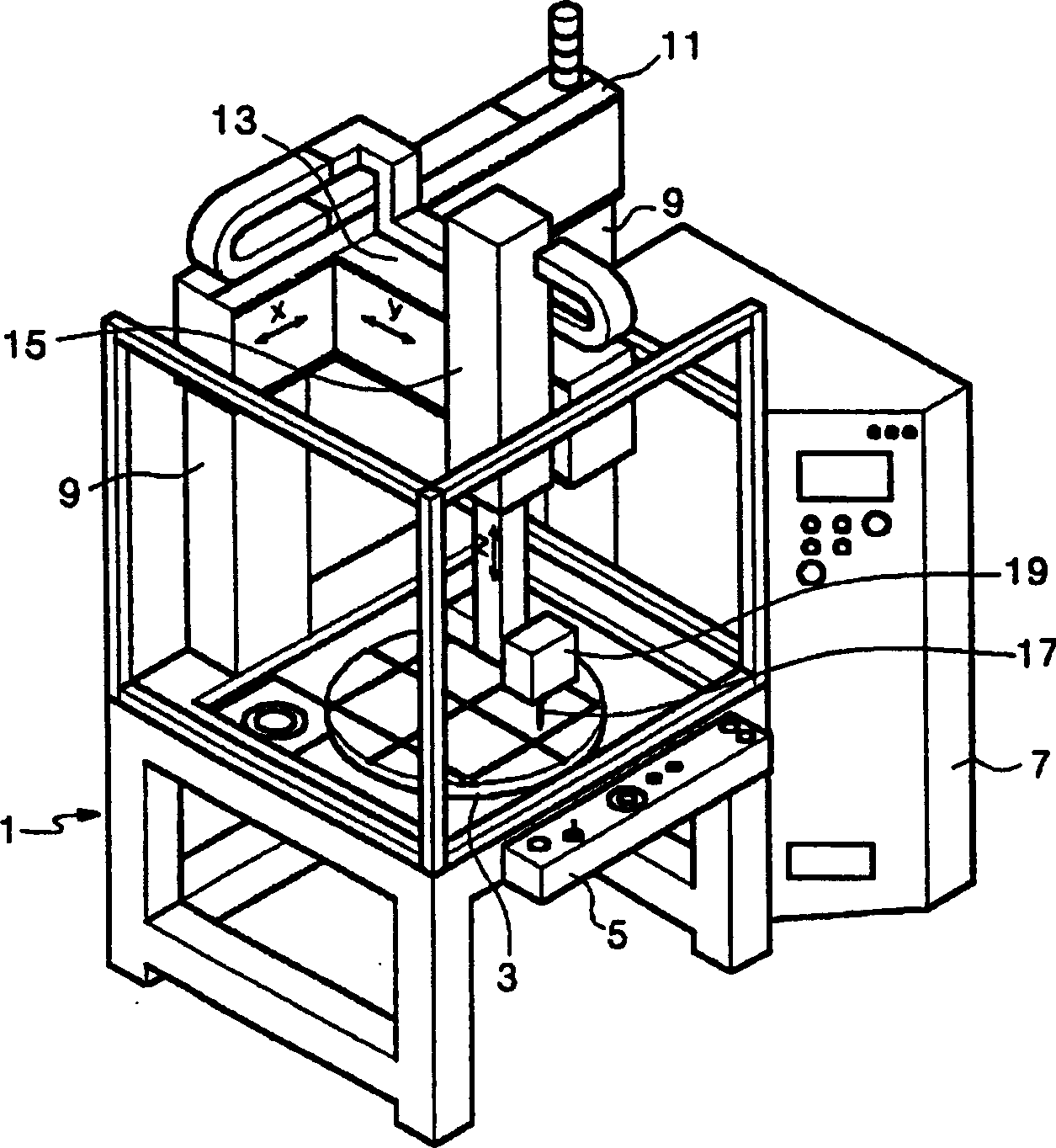

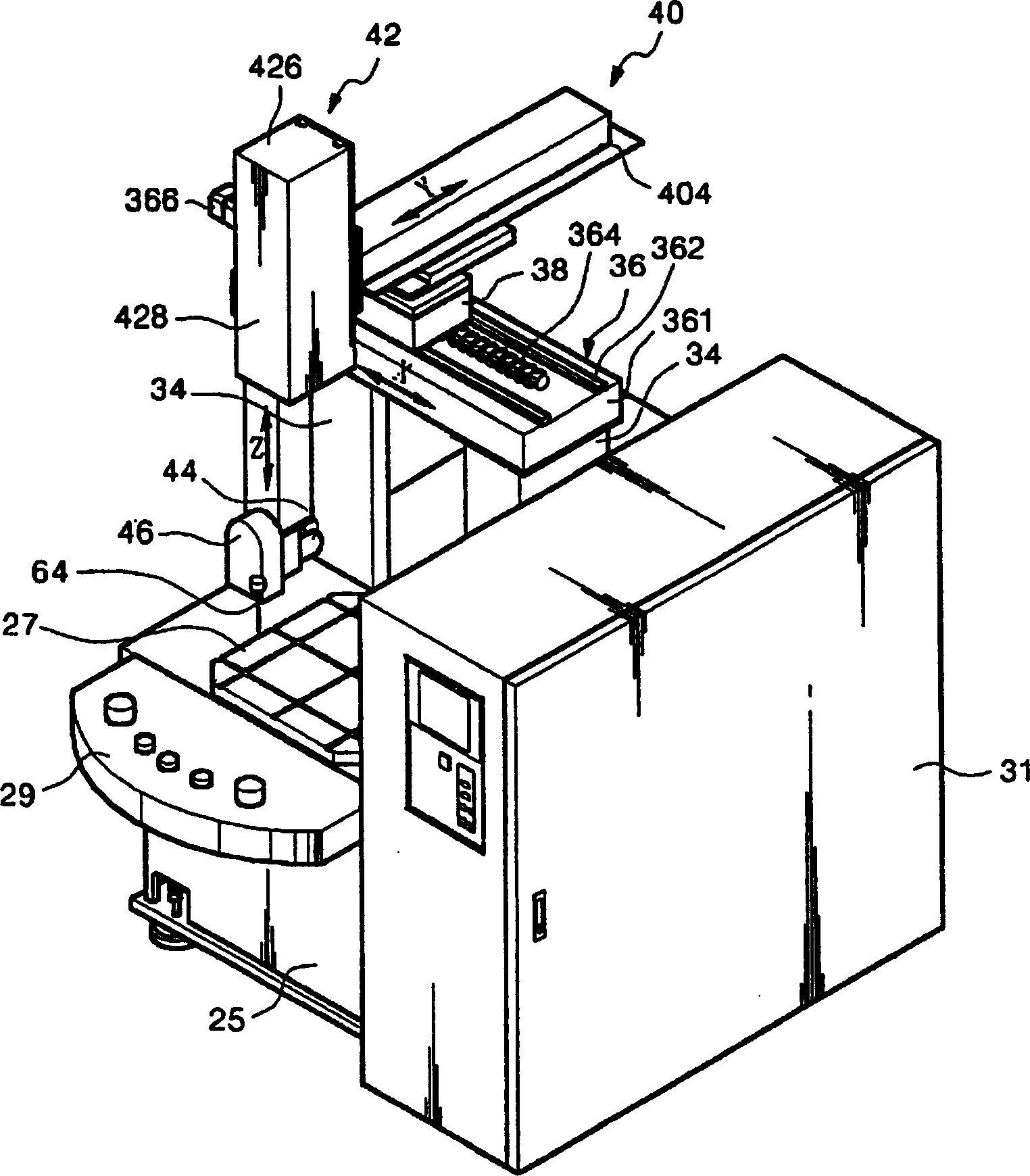

[0027] First, if figure 2 As shown, the polishing machine according to the preferred embodiment of the present invention includes a main body 25 provided with a support portion and a table 27 mounted on the main body 25 so as to rotate at a predetermined angle. The workpiece is fixed on the workbench 27 .

[0028] Furthermore, in the main body 25, a control unit 29 having various operation switches and buttons manipulated by the user to control all operations of the machine and a control box 31 for receiving information from the control unit 25 are equipped. Unit 29 and output control signals to various operating units.

[0029] A pair of cylinders 34 having a rectangular rod shape are fixed on both sides of the main body 25 . On the column body 34, a first conveying unit 36, a conveying block 38 and a second conveying unit 40 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com