Packaged unit with thermal fuse function

A technology of thermal fuses and closures, applied in the field of closures, can solve problems such as overheating, prolonged start-up lag, and unfavorable melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

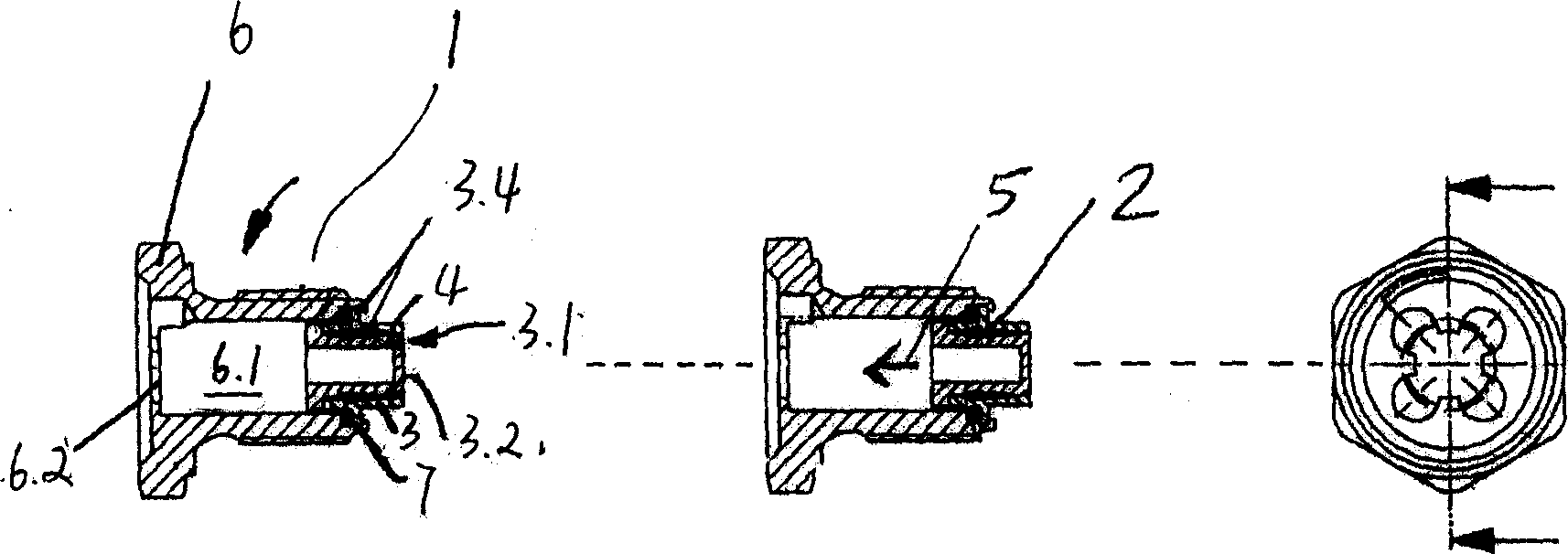

[0047] A best embodiment of the present invention will be described below with reference to FIGS. 2 to 4 .

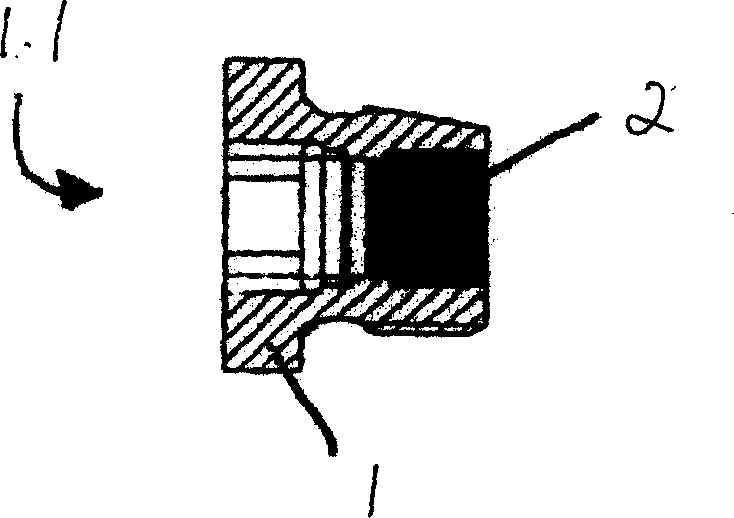

[0048] figure 1 Shown is a closure representing the state of the art. It can be seen that the closure has a closure body 1 in which a channel 1 . 1 is provided which is closed with a fuse element 2 . The fuse element is a melting solder, which is placed in the channel 1.1 over its entire cross-section and exhibits a great thickness.

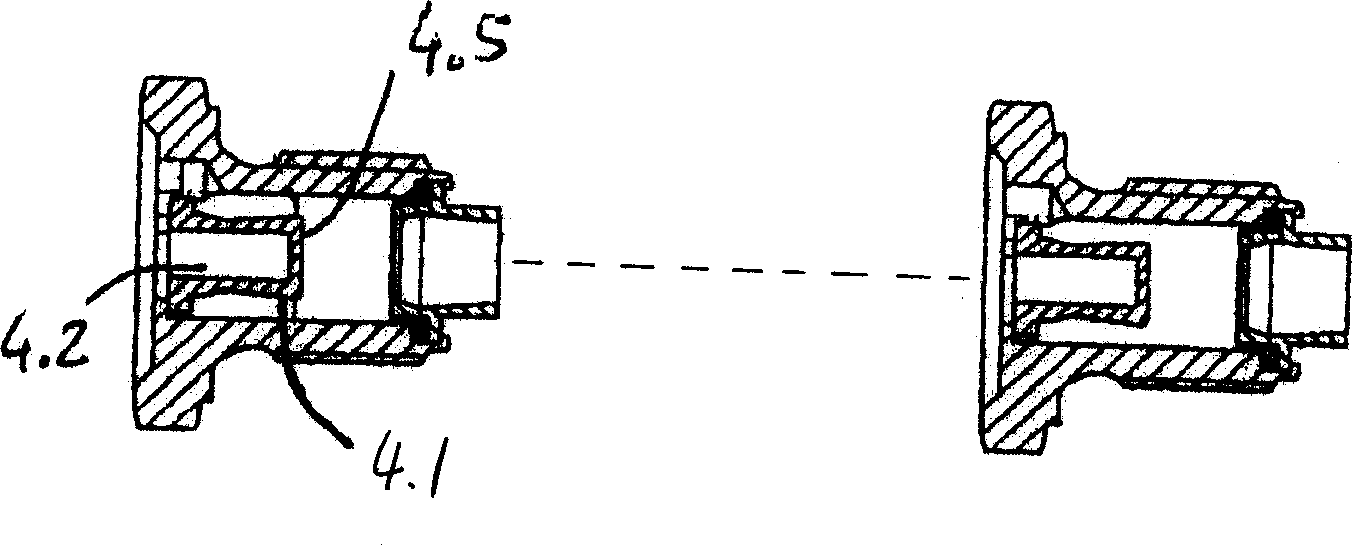

[0049] Also in Figure 4a with Figure 4b Also shown is a closure representing the state of the art for installation in fluid couplings. Such a closure in a hydraulic coupling has a certain start-up hysteresis, resulting in an overtemperature of the working medium of about 50K, which is related to the heating rate of the working medium. This means that the temperature of the fluid coupling working medium is about 50K higher than the rated temperature of the welding solder.

[0050] Figure 2 shows a closure according to the invention,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com