Power type filtering method

A filtration method and power technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problem of low filtration pressure and achieve the effects of low power consumption, energy saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

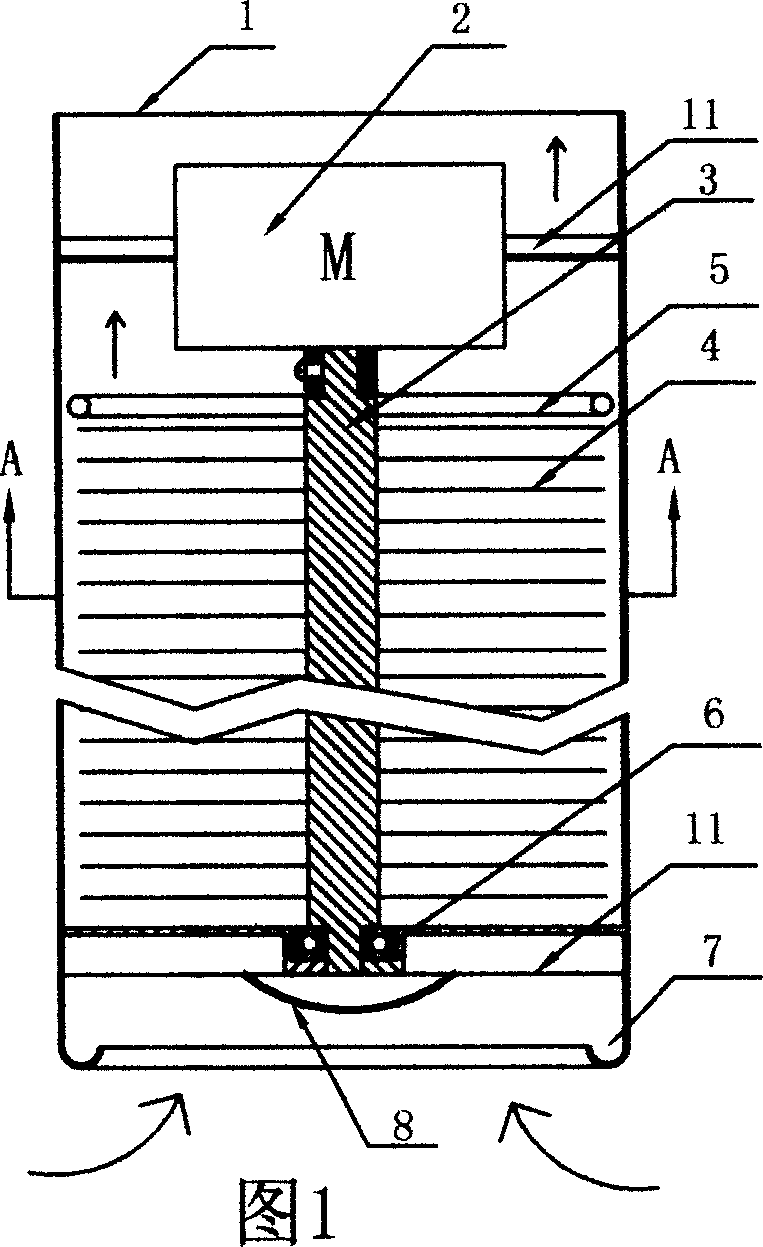

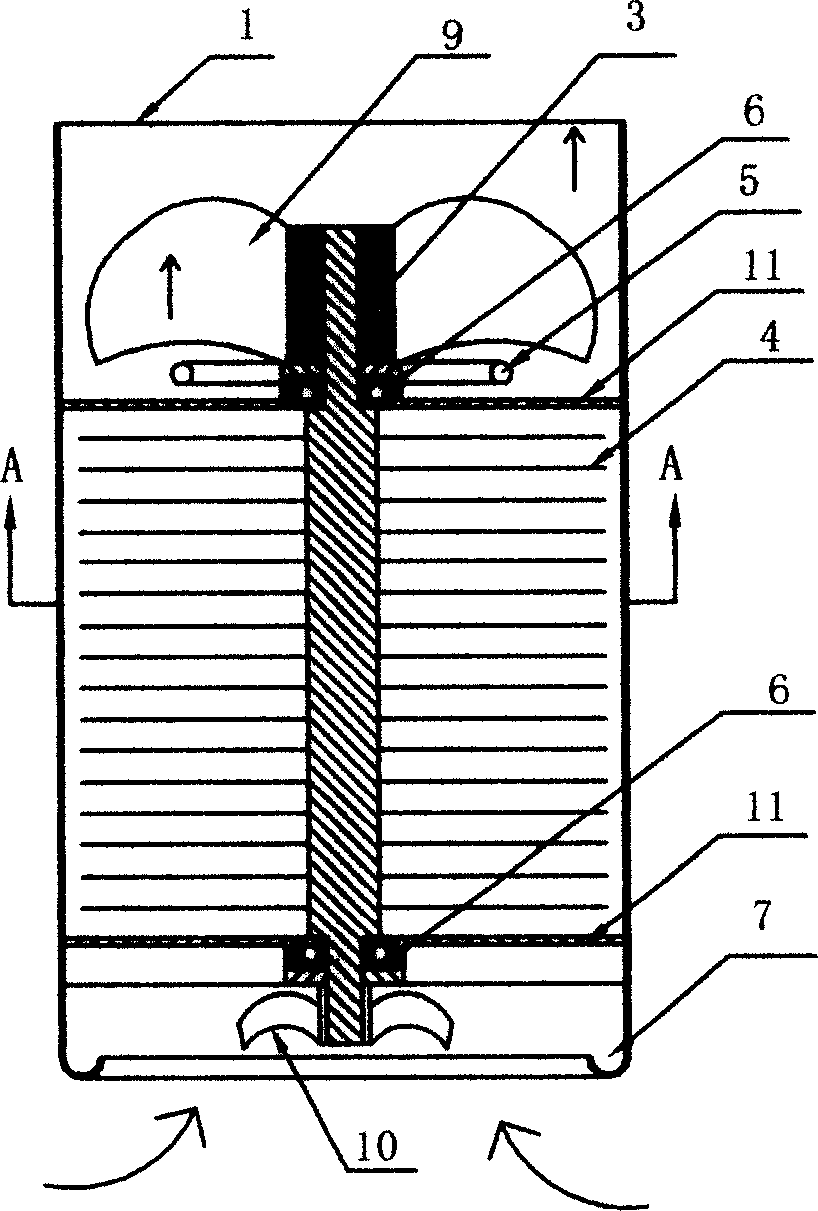

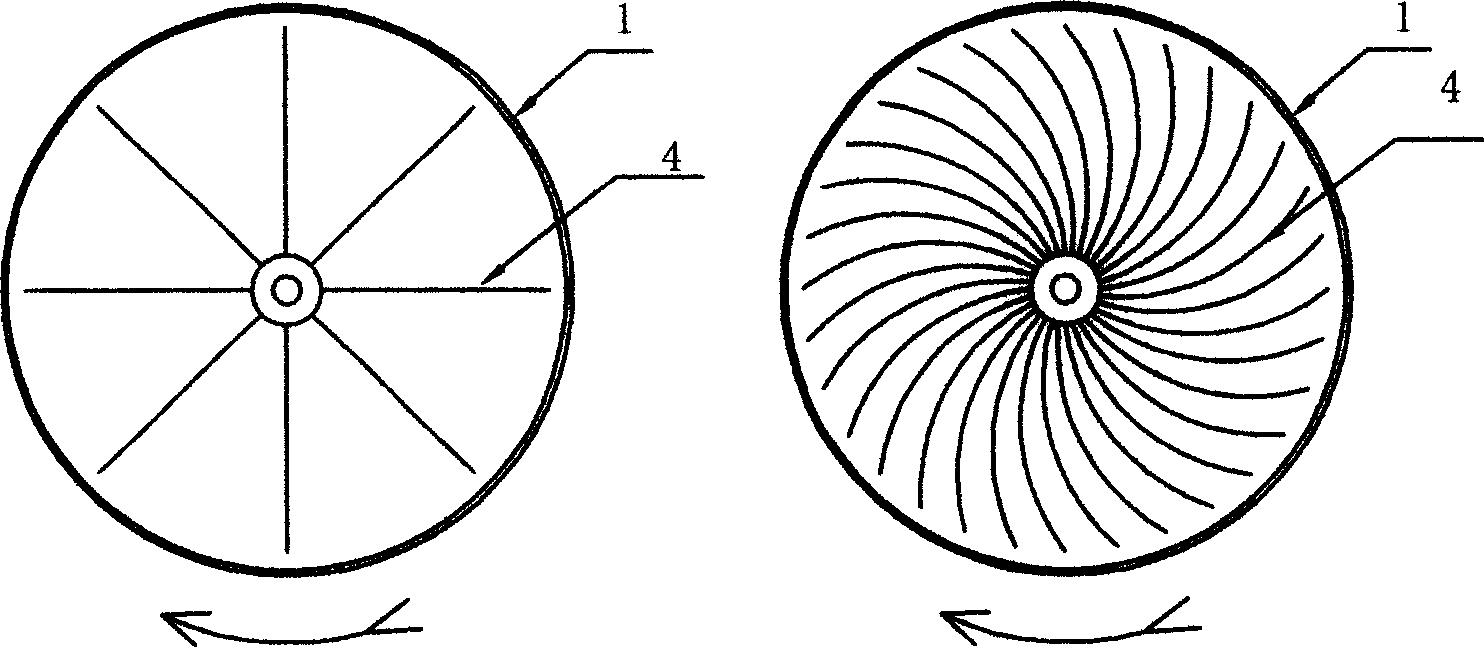

[0026] Fig. 1 is the electric motor of the first embodiment of the present invention working principle structural diagram, among the figure shell 1 is used for diversion air-flow and accepts the material to be filtered, and it also can directly use the pipeline of diversion material, cylindrical body. Motor 2 generally should be selected high-speed for use, also can use the gear of variable speed or other methods of variable speed when speed is not enough, improves the rotating speed that knocks down pin, knocks down leaf and is fixed on the fixed rod. Fixed bar 3, knock down pin, knock down leaf 4 they can be fixed in one by methods such as welding, screw. Washing liquid output part 5 is to set for increasing filtering effect, and spraying special washing liquid cleans and shoots down needle, shoots down leaf 4, also helps the removal of filtered material, but can't be used to the object that needs drying. The fixed bearing 6 is used for the support of the fixed rod 3 . Sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com