Composite modified crystal silcon glass sheet

A composite modification, glass plate technology, applied in the field of glass processing, can solve the problems of difficult processing, inflexible products, easy to break, etc., to achieve the effect of high strength, high product fastness, thermal expansion and contraction contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

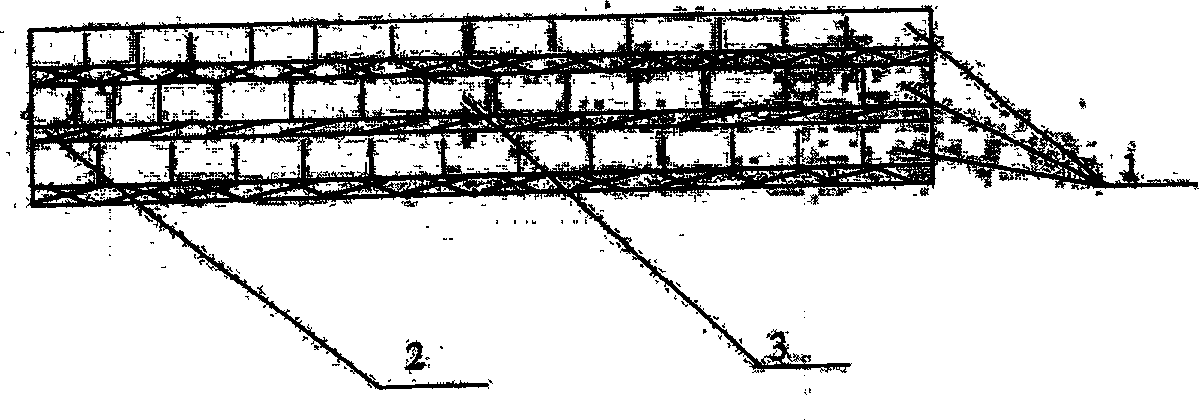

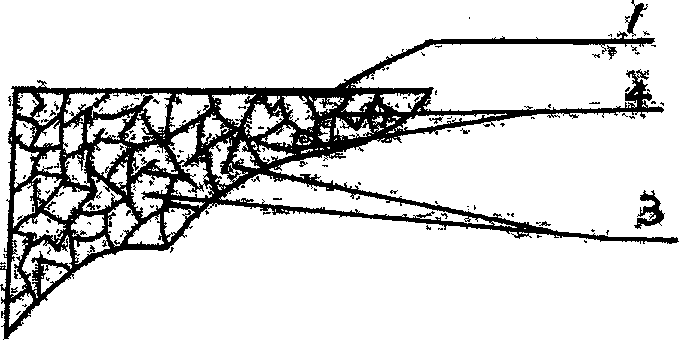

[0010] Embodiment 1. Take 3 crystalline silicon glass plates, lay a layer of transparent adhesive film 2 on the bottom surface of each crystalline silicon glass plate, break them evenly, and fill the gaps between each broken glass block 3 with glass adhesive 4. While forming the modified crystal silicon glass plate 1, three crystal silicon glass plates are laminated and glued together; finally, they are solidified to form a composite modified crystal silicon glass plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com