Method and device for magnetizing air and separating oxygen

A technology for air separation and oxygen, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation. It can solve the problems of expensive separation components, complicated oxygen production process, and short service life. The effect of low energy consumption and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

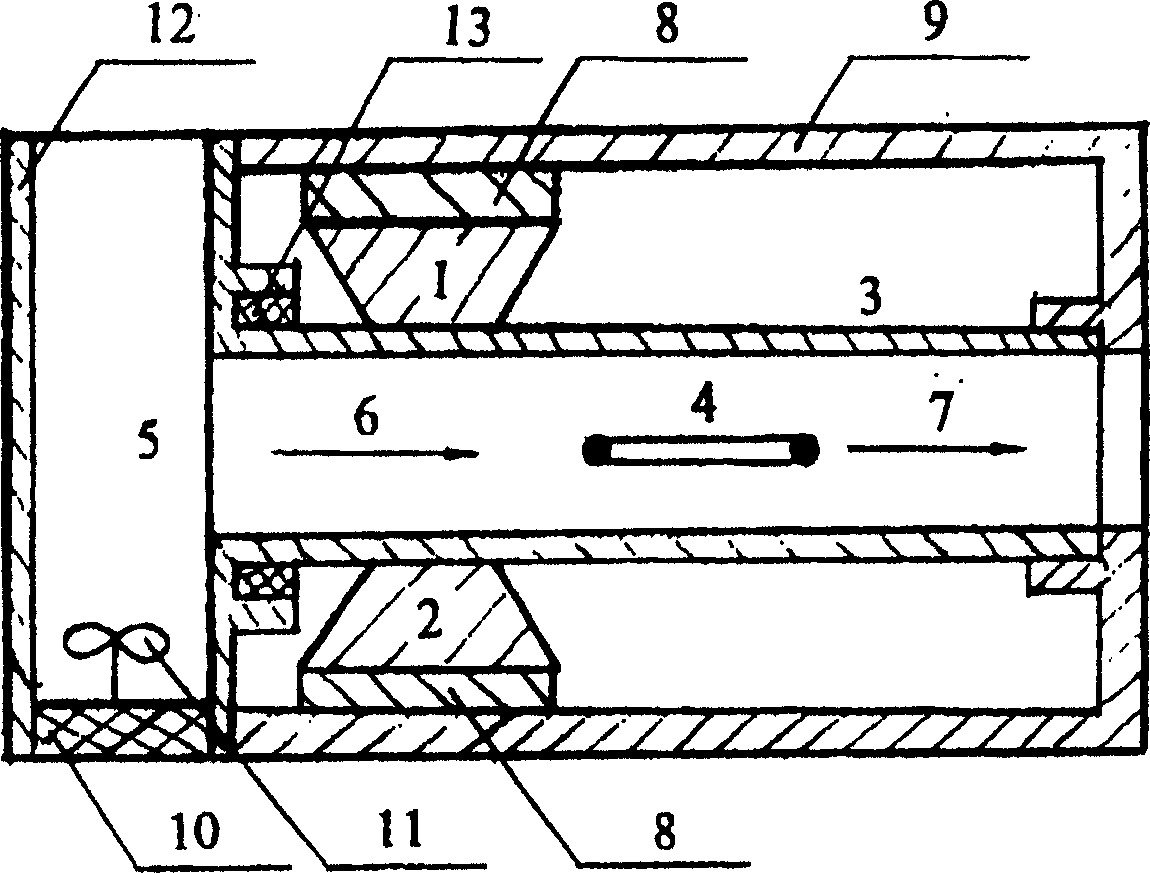

[0007] The present invention comprises basic parts: permanent magnet 1, 2, oxygen channel 3, electric heater 4 and auxiliary part: soft magnet 8, air filter cover 10, blower fan 11, air delivery channel 12 and shell 9, and oxygen channel 3 is made of non- Made of magnetically permeable material, the permanent magnets 1 and 2 are located symmetrically on both sides of one end of the oxygen channel 3 , generating an inhomogeneous magnetic field in the oxygen channel 3 . The shape of the permanent magnets 1 and 2 is conical, the smaller end is close to the oxygen channel 3, the larger end is fixed on the soft magnet 8, the residual magnetic field strength of the permanent magnet is greater than 1 Tesla, and the soft magnet 8 is fixed on the shell 9, which is mainly used to shield the magnetic field and form a magnetic circuit; one end of the oxygen channel 3 is fixed on the casing 9, and the other end is sealed and connected to the middle of the air delivery channel 12 through a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com