Blowing energy recovering method for blast furnace

A blast furnace blast and energy recovery technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as increased payback period of investment, and achieve the effects of shortened payback period, compact structure, and simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

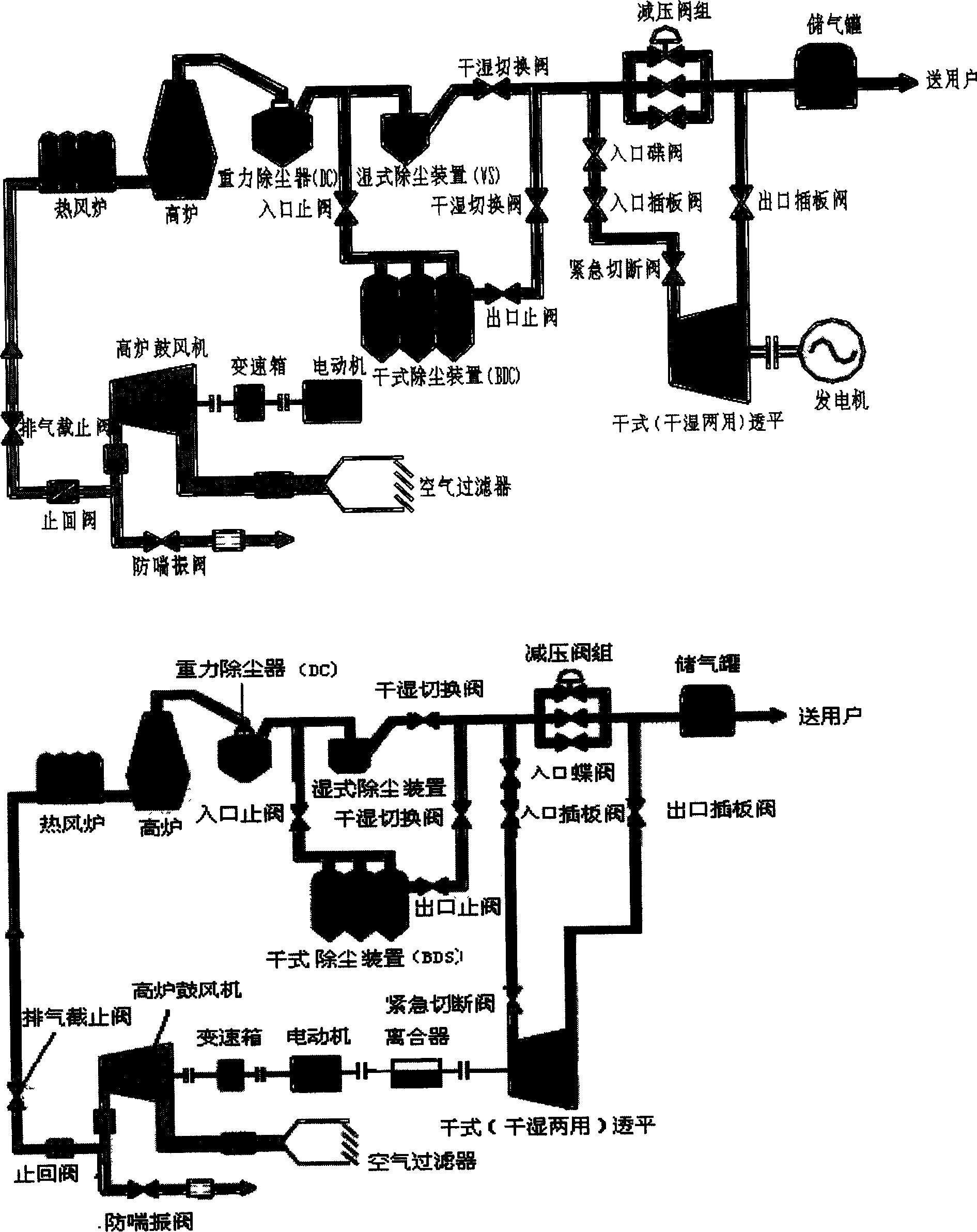

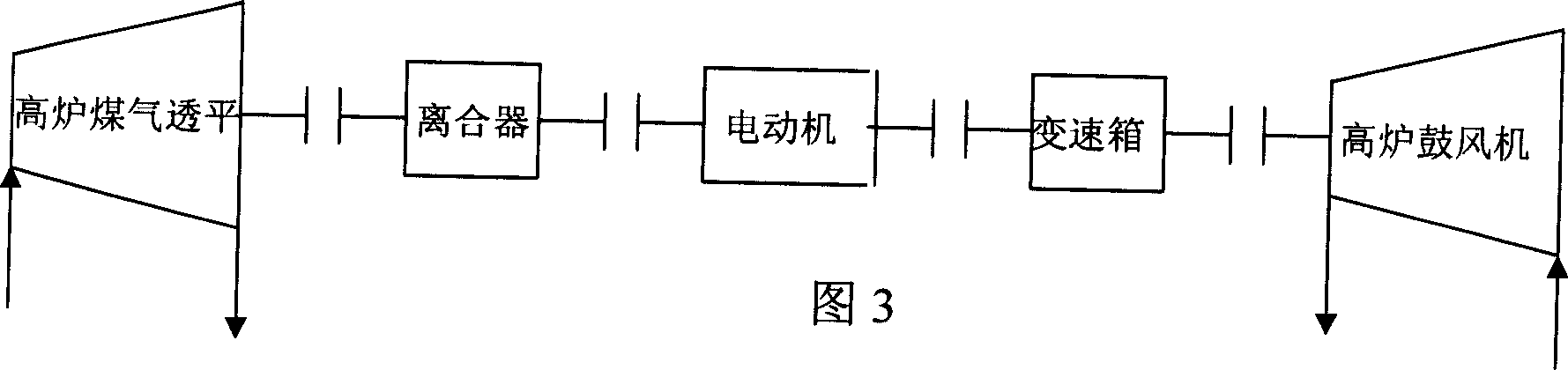

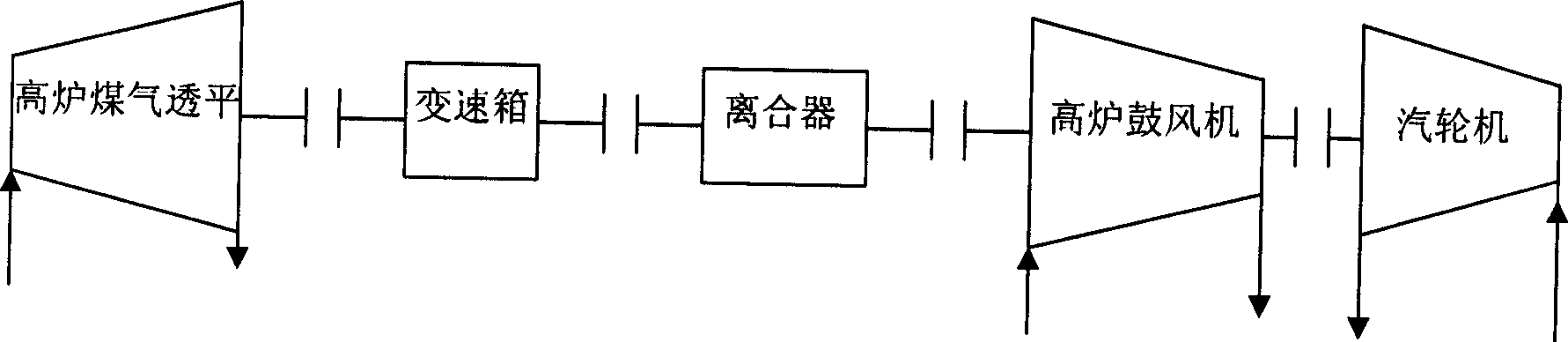

[0013] According to the above technical solution, the applicant directly connects the blast furnace gas turbine in the blast furnace gas residual pressure generator set with the electric motor or steam turbine of the original blast furnace blower set through the clutch, and cancels the residual pressure power generation system in the blast furnace gas residual pressure generator set, forming Blast Furnace Blast Energy Recovery Unit (BPRT), this unit uses the pressure energy and thermal energy of blast furnace top gas, a by-product of blast furnace smelting, to do work through turbine expansion to recover the energy of blast furnace gas. The blast furnace gas turbine and the electric motor jointly drive the blast furnace blower. Therefore, the BPRT unit is a blast furnace blast and secondary energy recovery device. The BPRT unit blows the blast furnace and at the same time plays the role of energy saving and environmental protection, which can bring considerable economic and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com