Hard sealing two-way disc valve

A hard seal and sealing surface technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of large flow resistance, increase the production cost of butterfly plates, and unsatisfactory flow lines of butterfly plates, etc., and achieve the goal of reducing flow resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

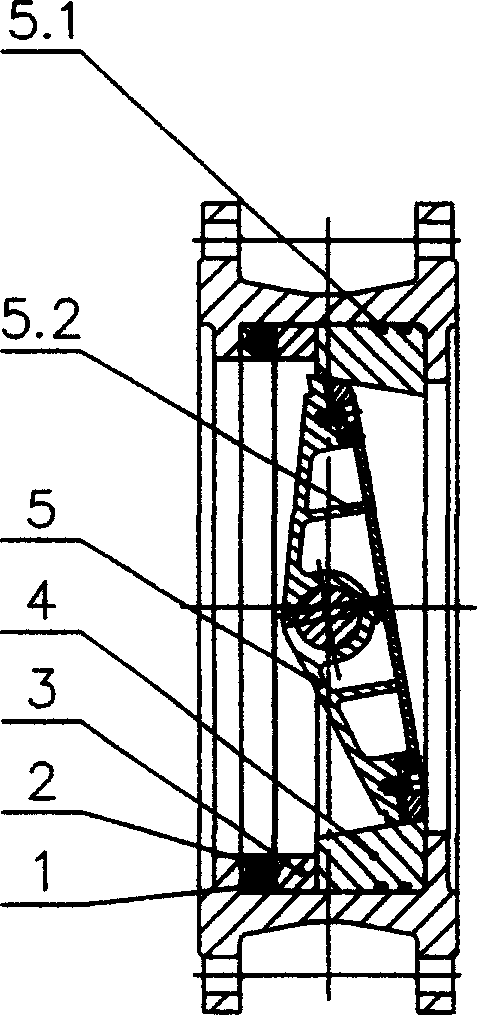

[0010] see figure 1 with figure 2 The hard-sealed two-way butterfly valve provided by the present invention includes a valve body 9, a butterfly plate 5 and a valve stem 7. The right part of the inner cavity of the valve body 9 is provided with a valve seat 4, and the outer surface of the valve seat 4 is the same as the valve body. There is a moving fit gap between the inner surfaces of the body 9, the right side of the valve seat 4 is the inner step 9.1 of the valve body 9 located on the right side of the valve inner cavity, and the left side of the valve seat is provided with a compression spring that presses it to the right 2. The valve seat 4 is provided with a cone-shaped inner hole. The butterfly plate 5 is located in the valve body 9 (in the inner cavity of the valve body 9), and is fixedly installed on the valve stem 7. The butterfly plate The outer surface of 5 is provided with a sealing surface, which matches the sealing surface on the inner conical surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com