Sewing machine with front lace automatic sewing function for knit goods

A sewing machine and knitwear technology, which is applied to program-controlled sewing machines, sewing machine components, knitting, etc., can solve the problems of complicated costs, high costs, and complicated operations, and achieve the effects of improving efficiency and reducing sewing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

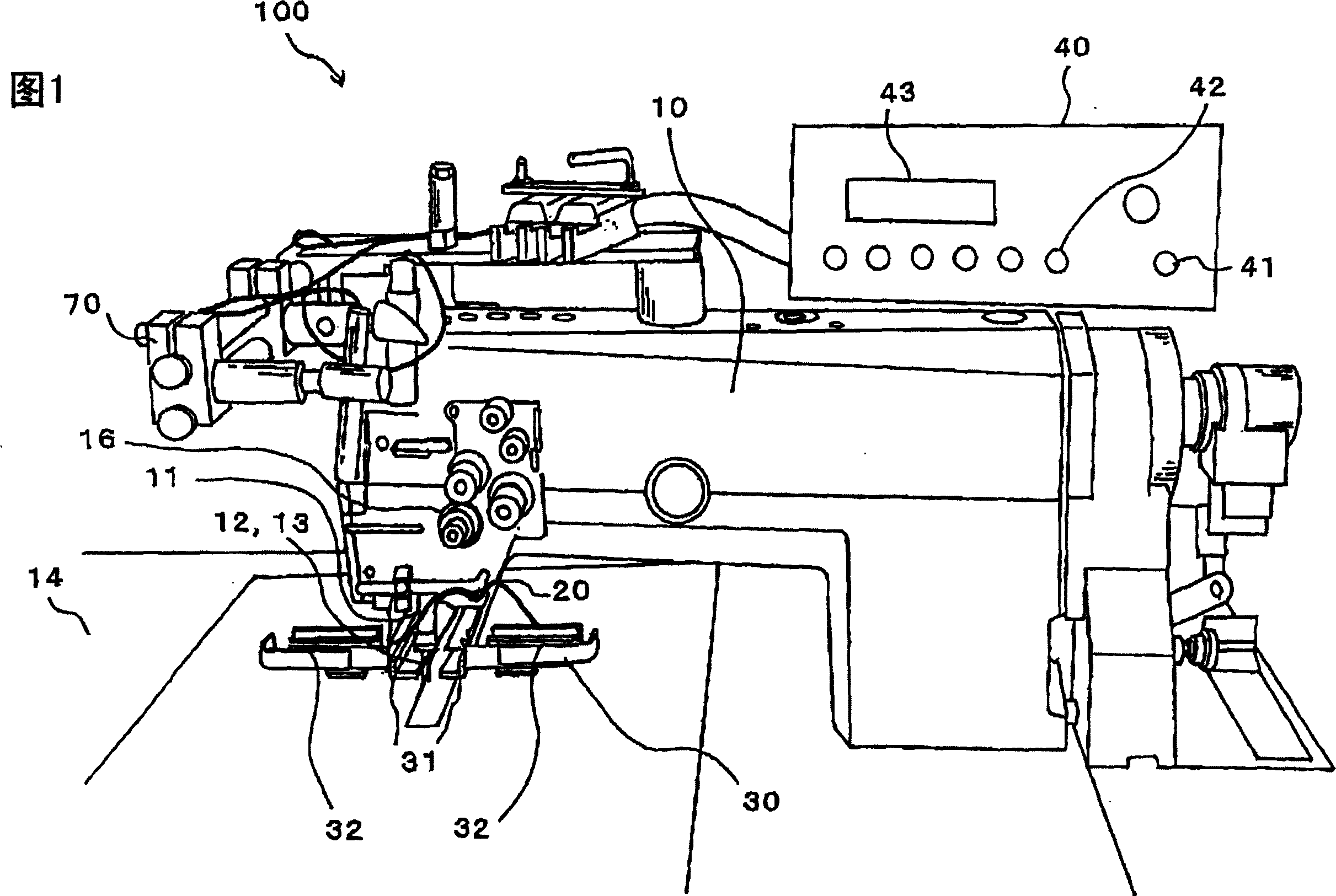

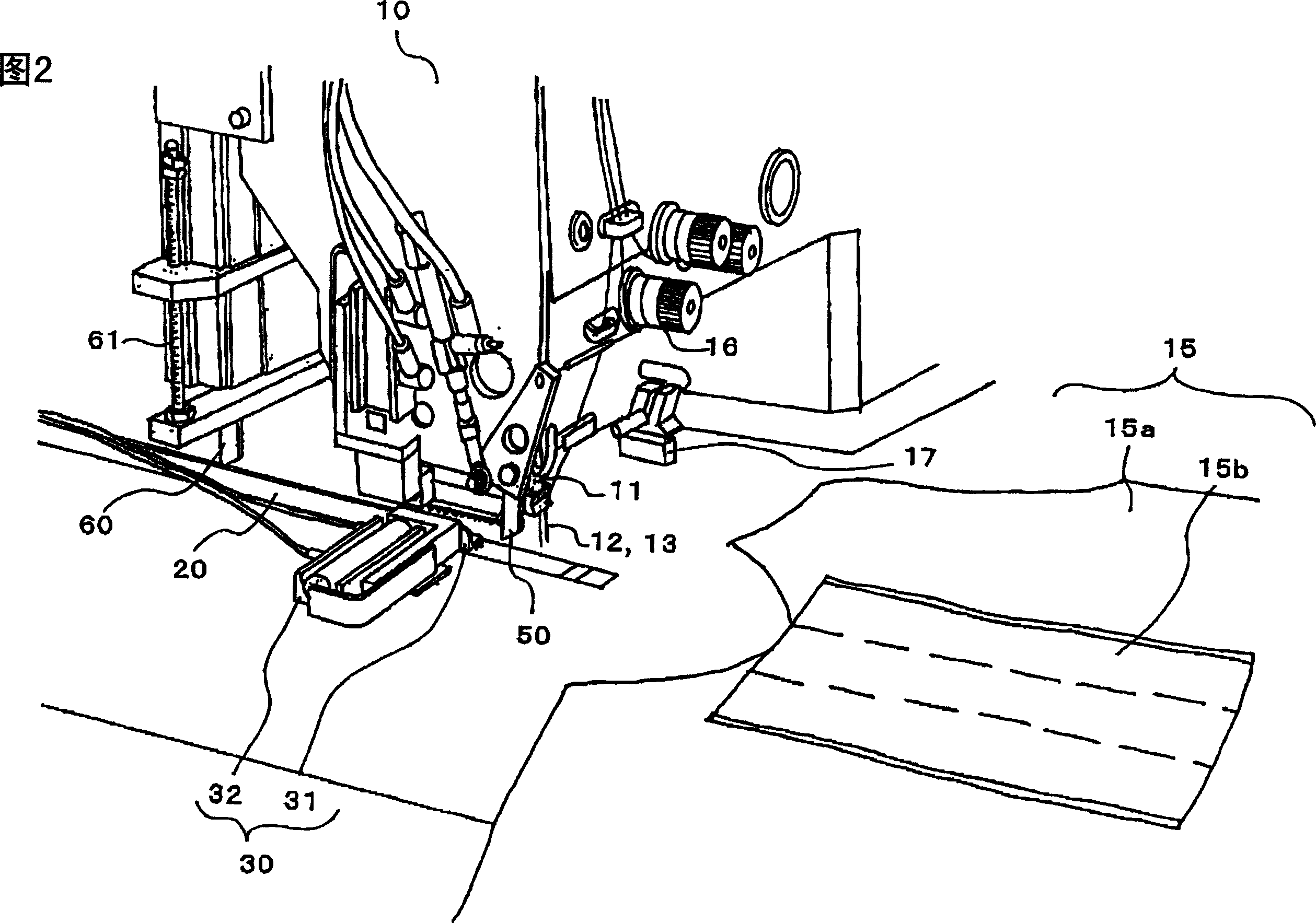

[0039] Referring to the drawings, the best embodiment for carrying out the present invention will be described based on the embodiments. The sewing machine of this embodiment is an example of an industrial sewing machine that automatically sews front gussets of knitted goods. FIG. 1 is an external view showing the industrial sewing machine with double needles according to the present invention. Fig. 2 is a perspective view of the automatic front gusset sewing machine for the knitwear seen in the horizontal direction.

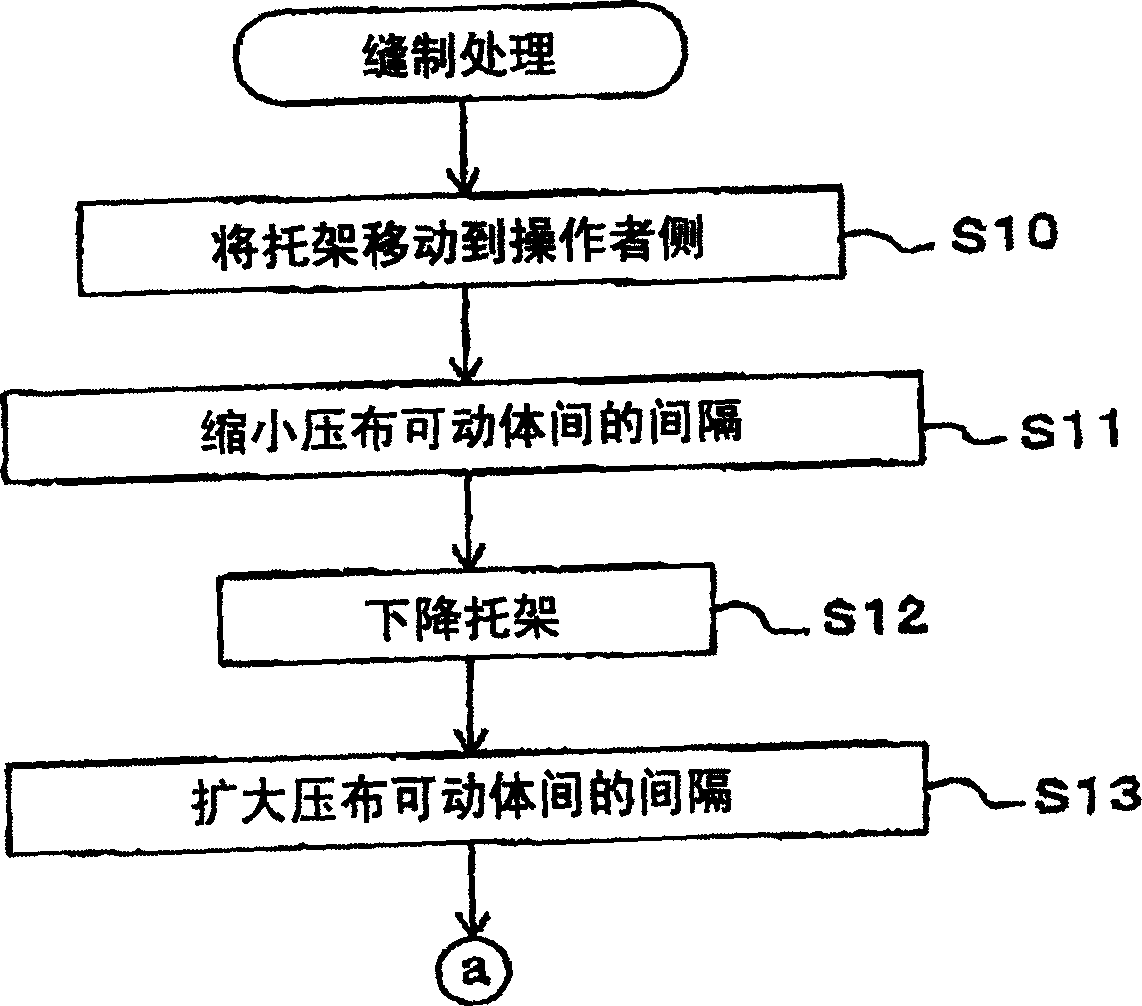

[0040] The sewing machine 100 has a sewing machine main body 10 , a bracket 20 , a movable body for pressing cloth 30 , a control unit 40 , an intermediate cutter 50 , a V-shaped cutter 60 , and an identifier 70 . And, the sewing machine 100 in the present embodiment is controlled by the control unit 40 to the bracket 20, the cloth pressing movable body 30, the middle cutter 50 and the V-shaped cutter 60; Cut the middle of the two sewing lines while sewing whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com