Efficient and stable roller car for back stitching

A roller car and stable technology, applied in the field of sewing machinery, can solve the problems of increasing labor intensity of workers, reducing sewing efficiency, and increasing sewing cost, so as to reduce labor intensity of workers, improve sewing efficiency, and reduce sewing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

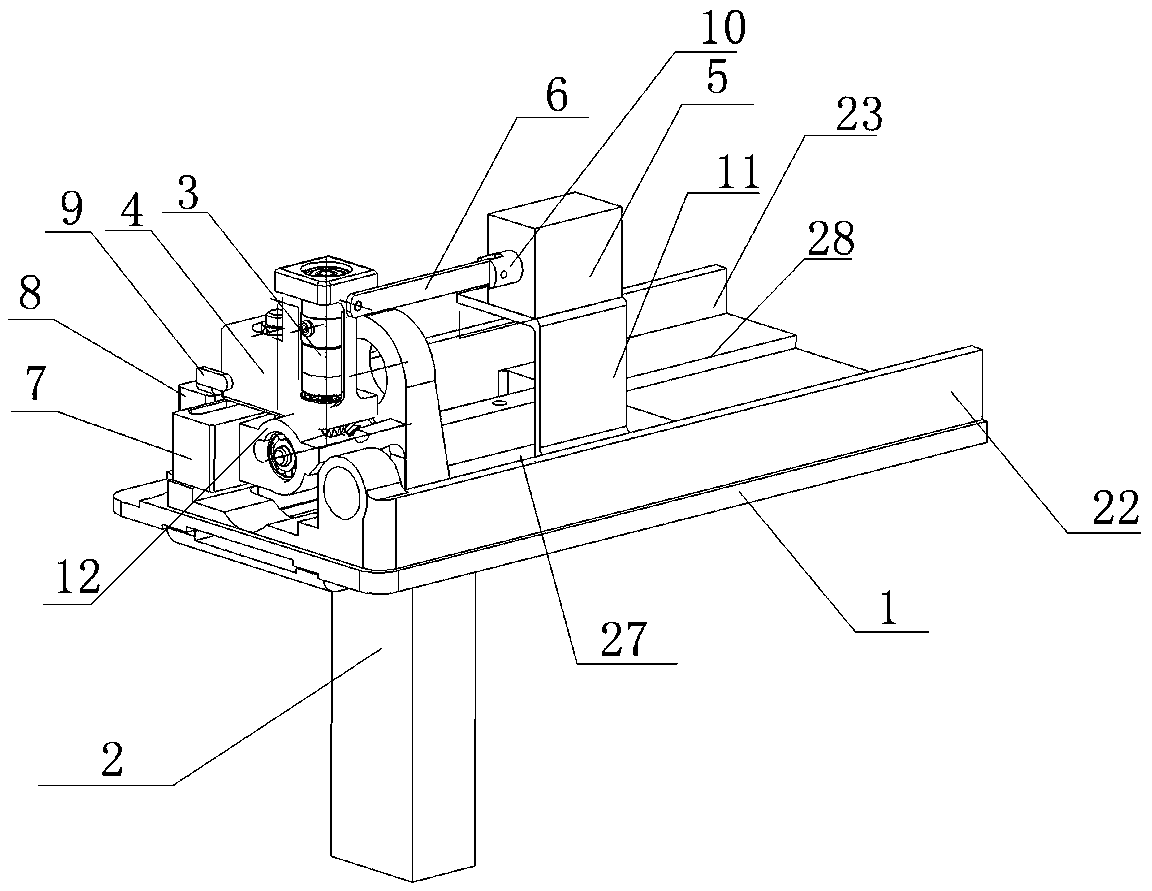

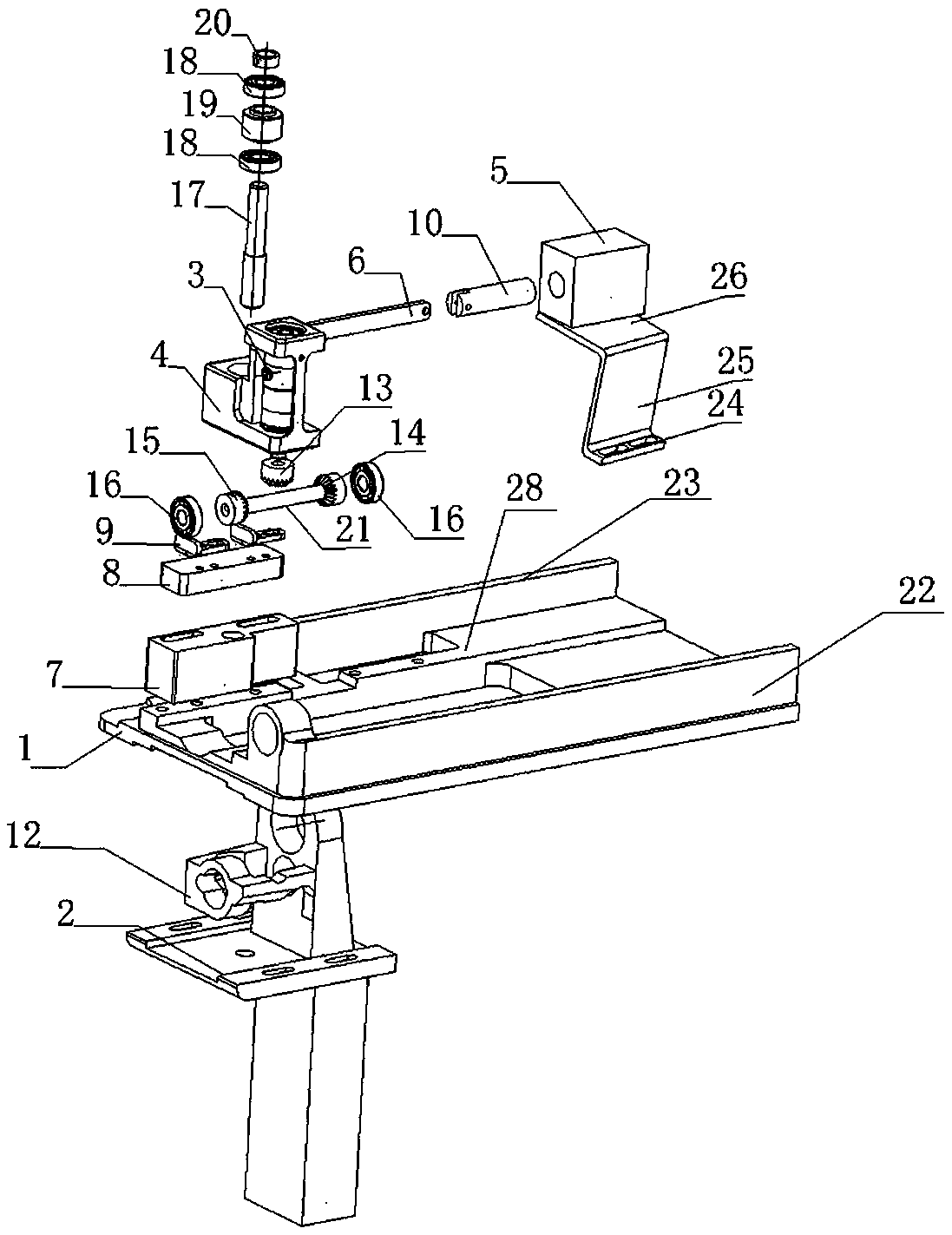

[0043] Such as Figure 1-2As shown in and 5-6, a roller car capable of efficient and stable reverse sewing includes a machine head and a middle seat structure, and the machine head includes a machine head casing and a first electromagnet and a first magnetic steel shaft arranged in the head casing And the first one-way bearing rotation mechanism, the middle seat structure includes the bottom plate 1, the middle seat 2 arranged on the bottom plate 1, the gear transmission mechanism arranged on the middle seat 2 and the second one-way bearing rotation mechanism connected to the gear transmission mechanism Mechanism, the first electromagnet and the first one-way bearing rotating mechanism are connected by an eccentric shaft structure, the first one-way bearing rotating mechanism includes the first one-way bearing shaft, the one-way bearing seat, the first one-way bearing Palin shaft bearings are arranged at the upper end of the Palin shaft; the structure of the eccentric shaft in...

Embodiment 2

[0046] Such as Figure 3-4 As shown, the horizontal mounting section 24 is fixed on the right fixed platform 28 by fastening screws.

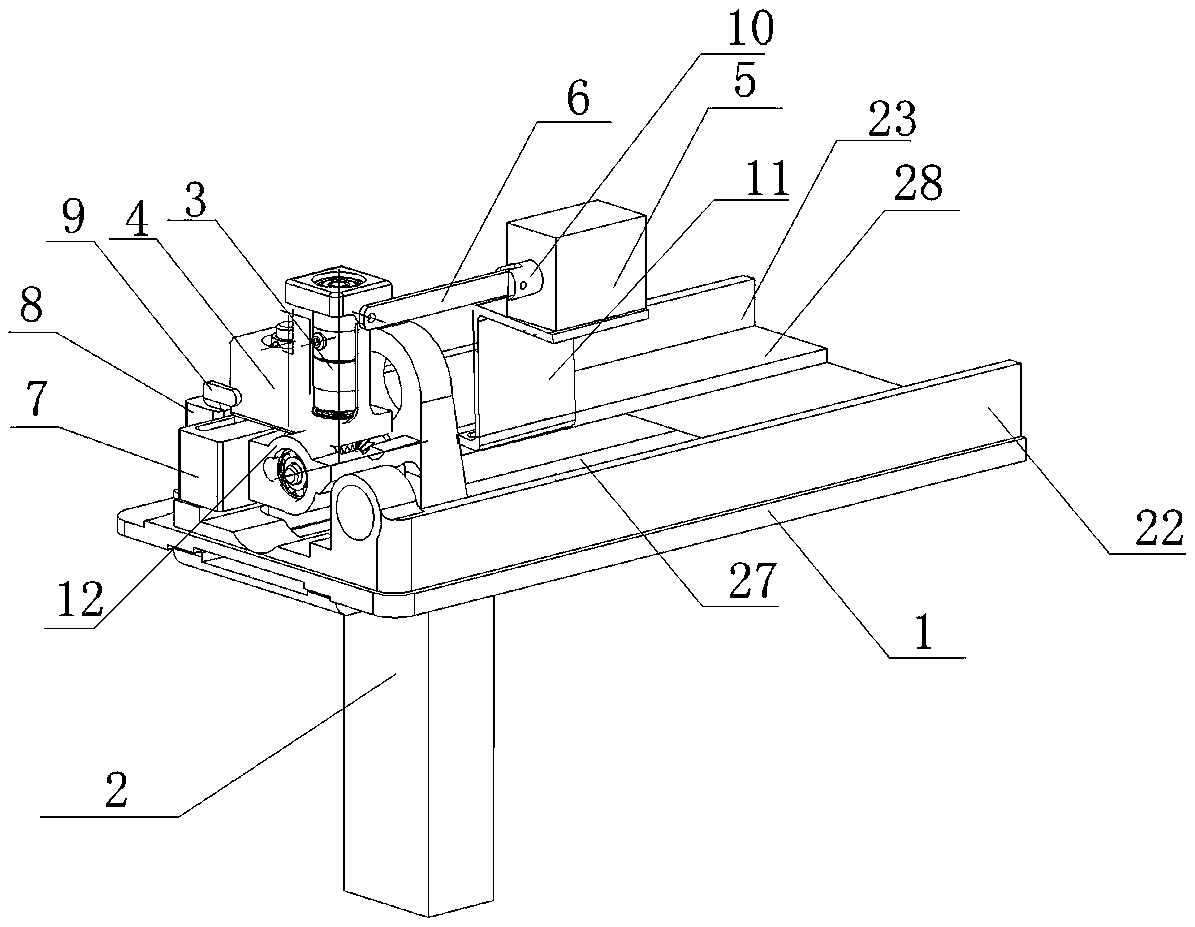

[0047] The working process of the present invention: when the roller cart is sewing normally, the presser foot gear at the head position of the roller cart meshes, and the cloth pressing gear rotates forward; the driving gear on the middle seat structure meshes with the forward rotation gear for transmission, and the forward rotation gear Drive the cloth feed wheel to rotate forward;

[0048] When the roller car needs reverse sewing, the controller automatically controls the second electromagnet of the middle seat structure to be energized, and the second electromagnet pushes the second connecting rod to make the bearing shaft fixing seat swing around the swinging fixed shaft, so that the driving gear moves to the same position as The meshing position of the counter gear is engaged with the counter gear for transmission, and the counter gear d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com