A fully automatic control device and control method for a sewing machine mop wheel

A control device and control method technology, applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of complex structure of the mop wheel control mechanism, limit the work efficiency of operators, and affect the quality of sewing, etc., to achieve fully automatic Control and guarantee the sewing quality and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

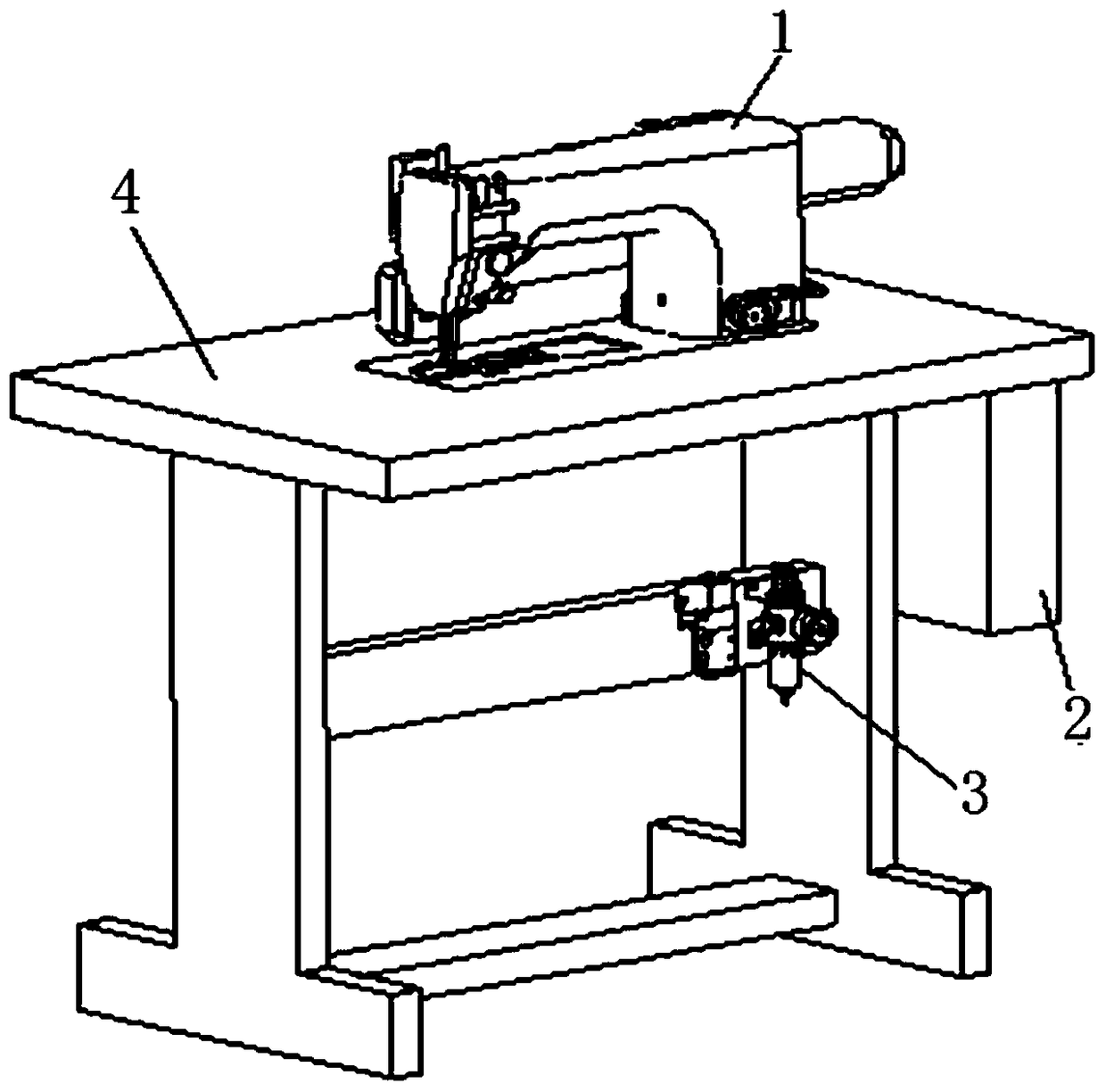

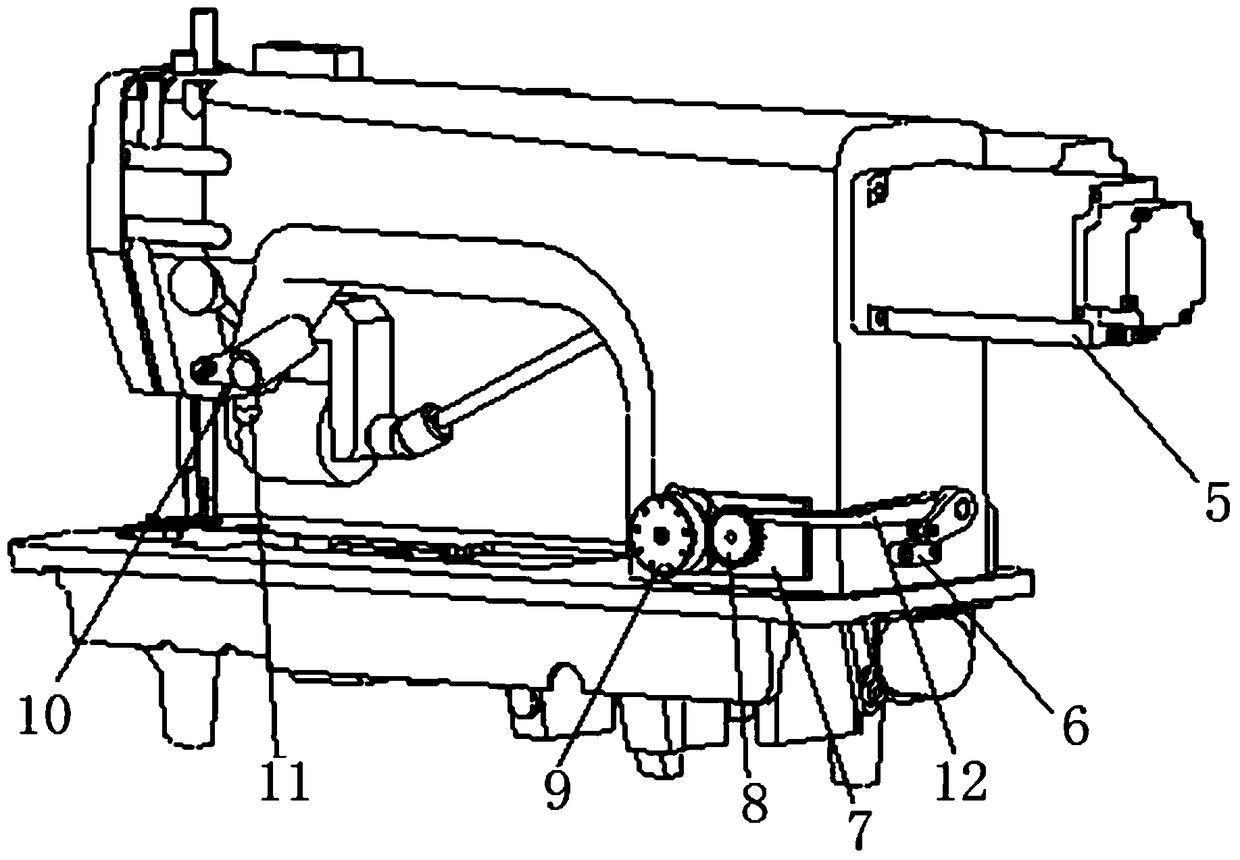

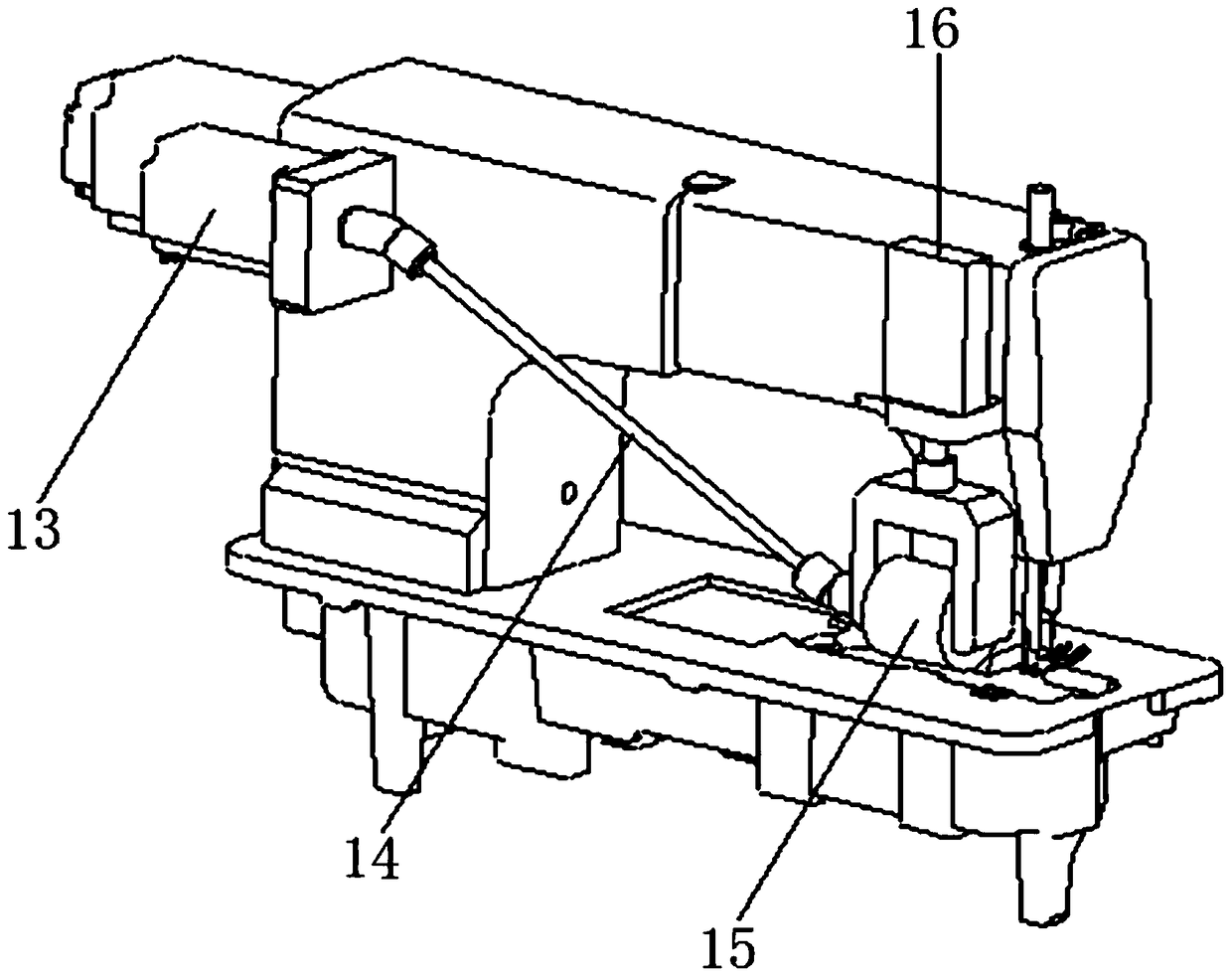

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0031] The present invention realizes the full automation of the control of the sewing machine mopping wheel by controlling the mopping wheel of the sewing machine and synchronously adjusting the sewing machine needle distance adjustment mechanism, reverse stitching action and sewing speed.

[0032] For this reason, the scheme that the present invention adopts mainly comprises following two aspects:

[0033] 1. The feeding amount of the mop wheel of the sewing machine is controlled by the stepping motor, and it is adjusted synchronously with the needle pitch adjustment mechanism. Specifically, firstly, by compiling the internal program of the stepping motor driver, each stitch value corresponds to a stepping motor of the mop wheel The electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com