Power source chassis of wireless electric hot-water pot

A technology for power bases and hot water pots, which is applied to cooker brackets and heating devices, etc. It can solve problems such as poor contact between the electrodes of the water pot and power base, damage to the surface of the power base, and easy warping of plastics. To achieve the effect of enriching styles and varieties, increasing styles and varieties, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

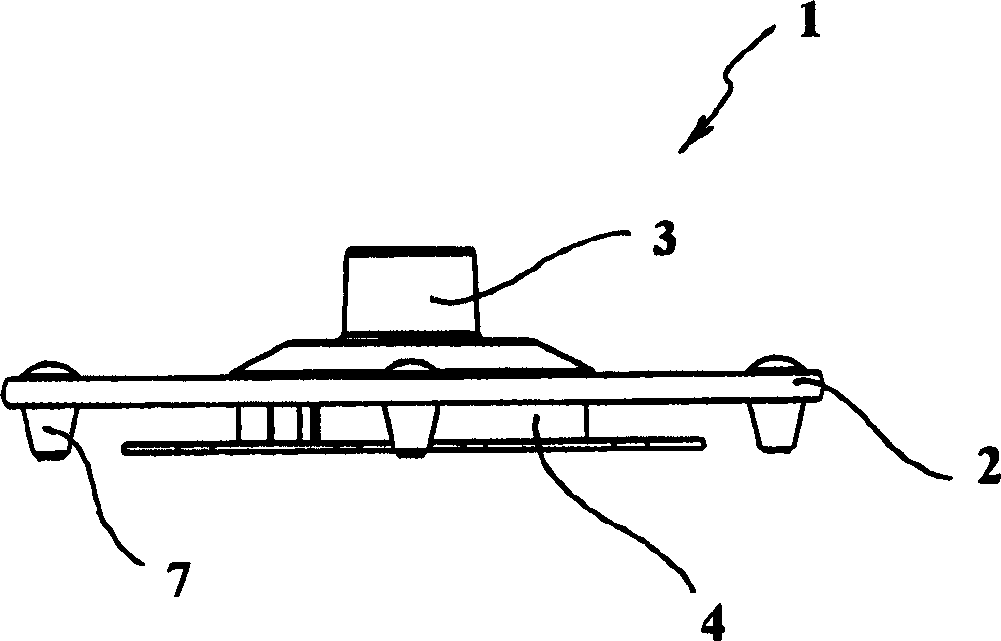

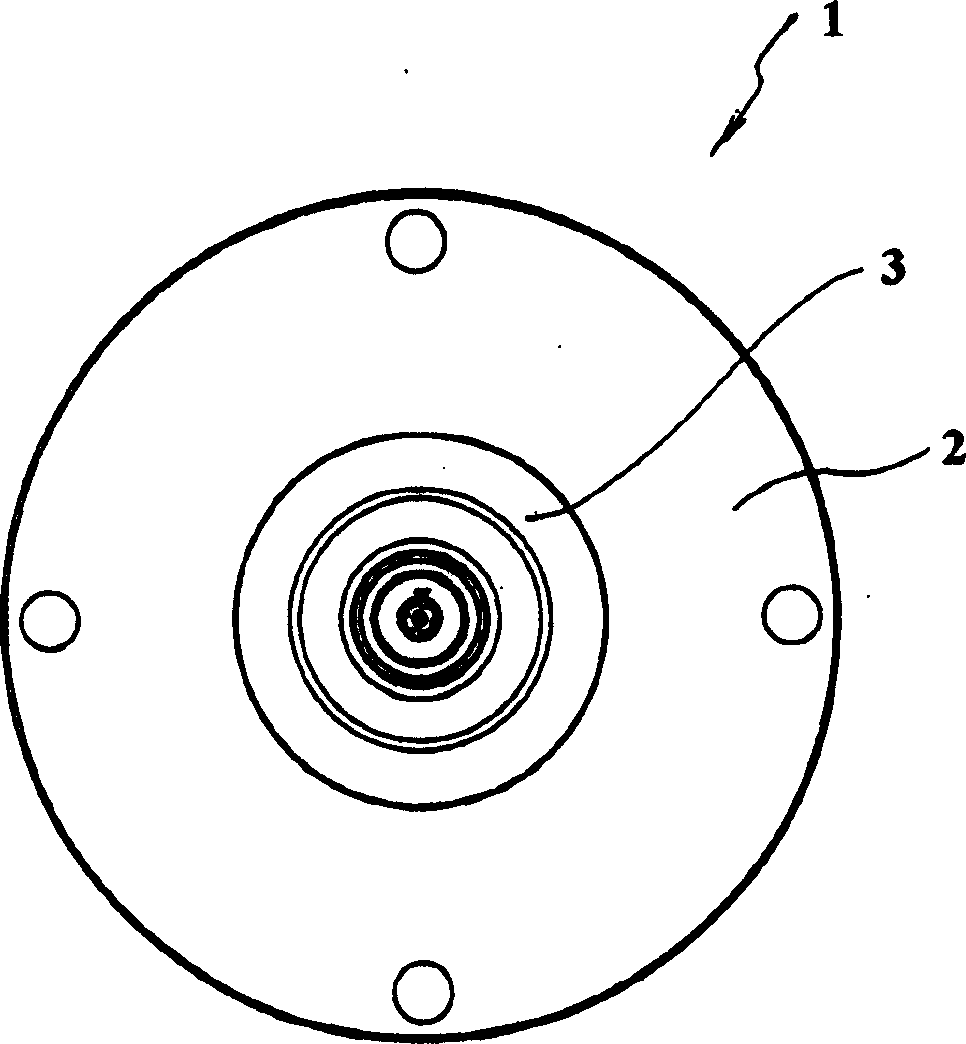

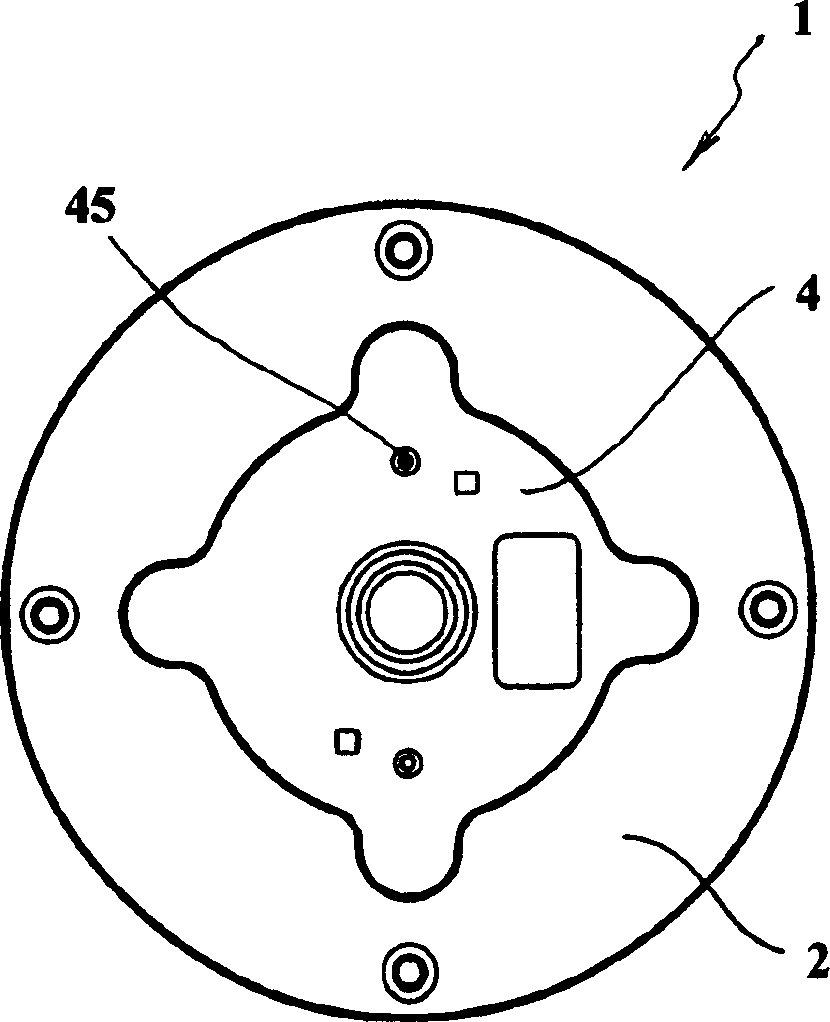

[0018] Combine below Figure 1-4 The structure of an embodiment of the power supply base 1 of the wireless electric hot water cooker of the present invention will be described in detail. Such as Figure 4 As shown in the figure, the power base 1 includes a transparent or translucent base plate 2, a base upper shell 3, a base lower shell 4, a power connector 5 arranged between the base upper shell 3 and the base lower shell, and Power cord power plug 6 and multiple base feet 7.

[0019] The base plate 2 is mainly a circular glass plate 21, preferably made of strengthened glass, with a large hole 22 in the middle, and at least two upper shell mounting holes 23 are provided along the periphery of the large hole 22. A plurality of base foot mounting holes 24 are provided near the outer circumference, and there are four in this embodiment. The above big hole 22 is in Figure 4 It is shown as a round hole, but it is not limited to the round hole shape, and other shapes are also possible....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com