Torque adaptive winding type motor

A winding type, electric motor technology, applied in the field of stator and rotor, can solve the problems of discontinuous adjustment of external resistance of the rotor, poor assembly process, rough torque adjustment, etc., and achieve convenient daily maintenance, low production cost and simple manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

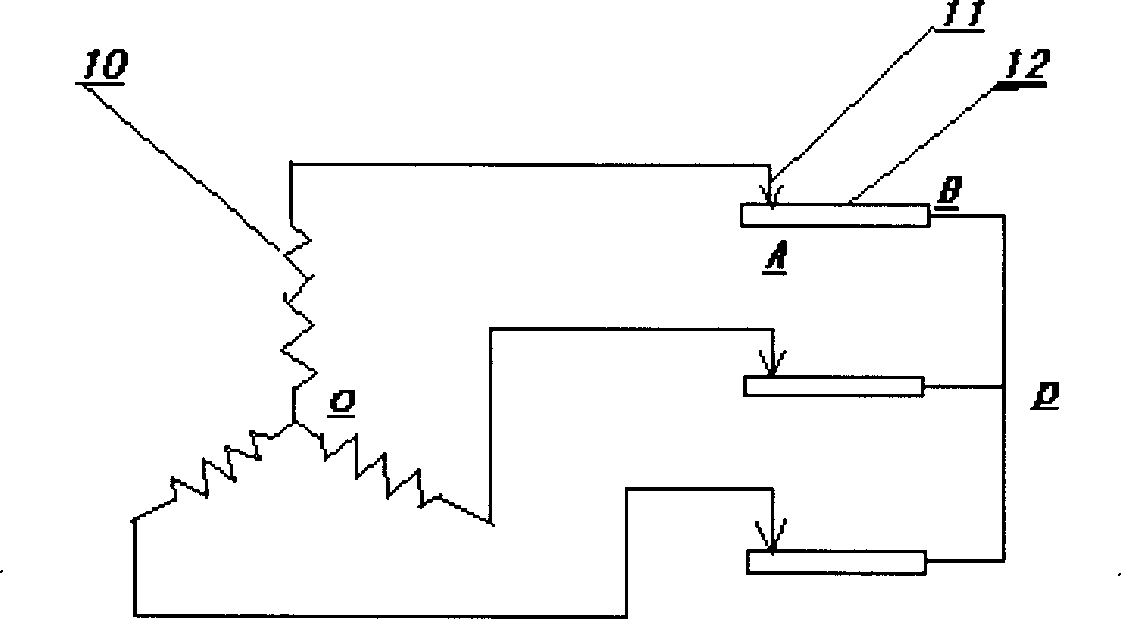

[0017] This example is a torque adaptive winding motor for moving a beam. Set its rated speed as 1460r / min. When the motor speed reaches 1400r / min, it can be considered that the start is completed. Start-up requires a resistance of R 0 , the length of the channel is L.

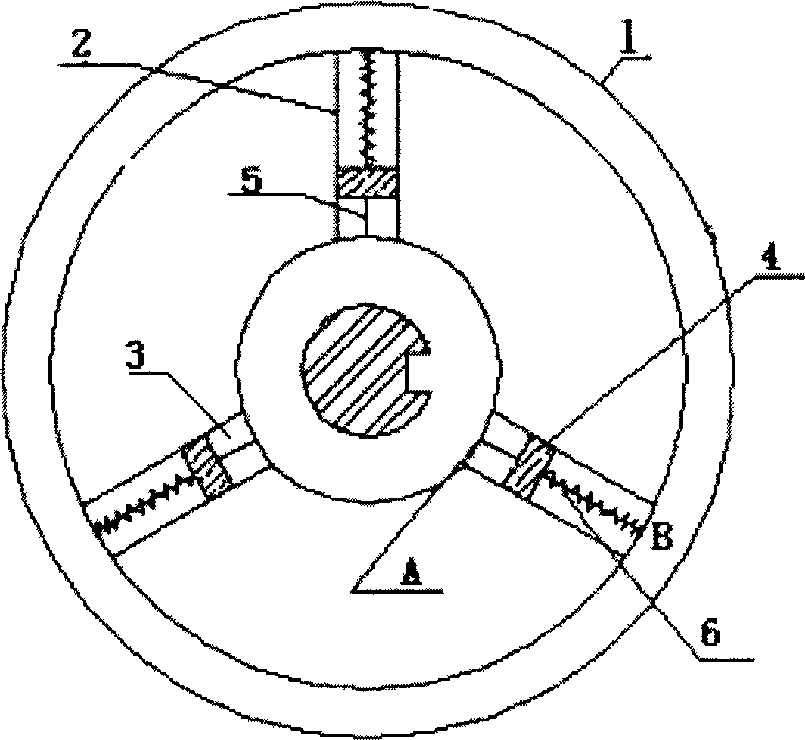

[0018] The wound motor consists of a motor stator with armature windings, a motor rotor equipped with a centrifugal controller, two end covers, a housing, bearings, etc.

[0019] The stator of the motor is composed of a stator core and an armature winding, and its structure is the same as that of a squirrel-cage AC asynchronous motor and its armature winding.

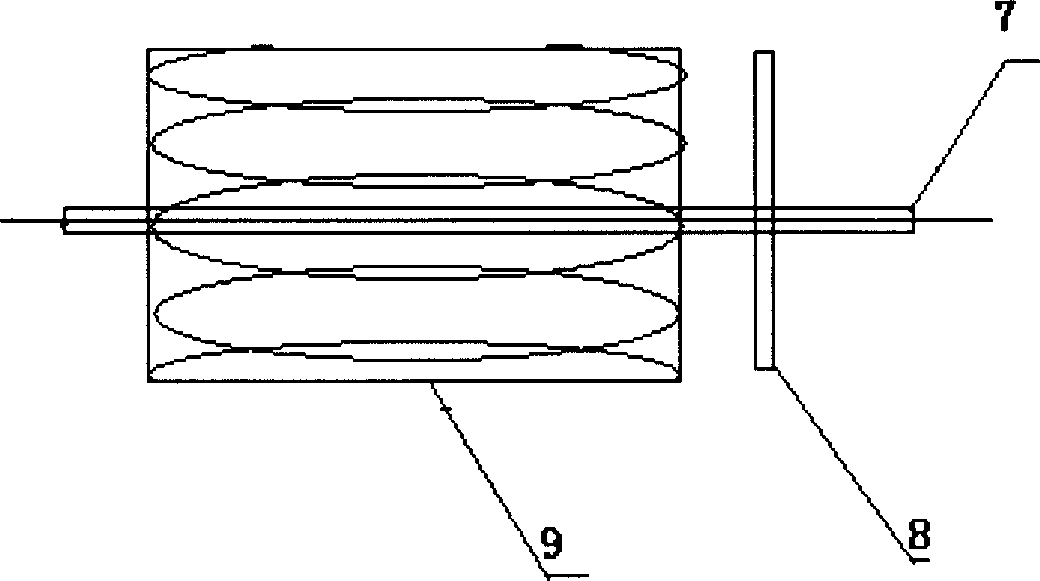

[0020] Its rotor structure see figure 2 , except that the rotor has a rotating shaft 7 and a rotor winding 9 of an ordinary wound motor, a centrifugal controller 8 is fixedly installed on the rotating shaft 7 .

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com