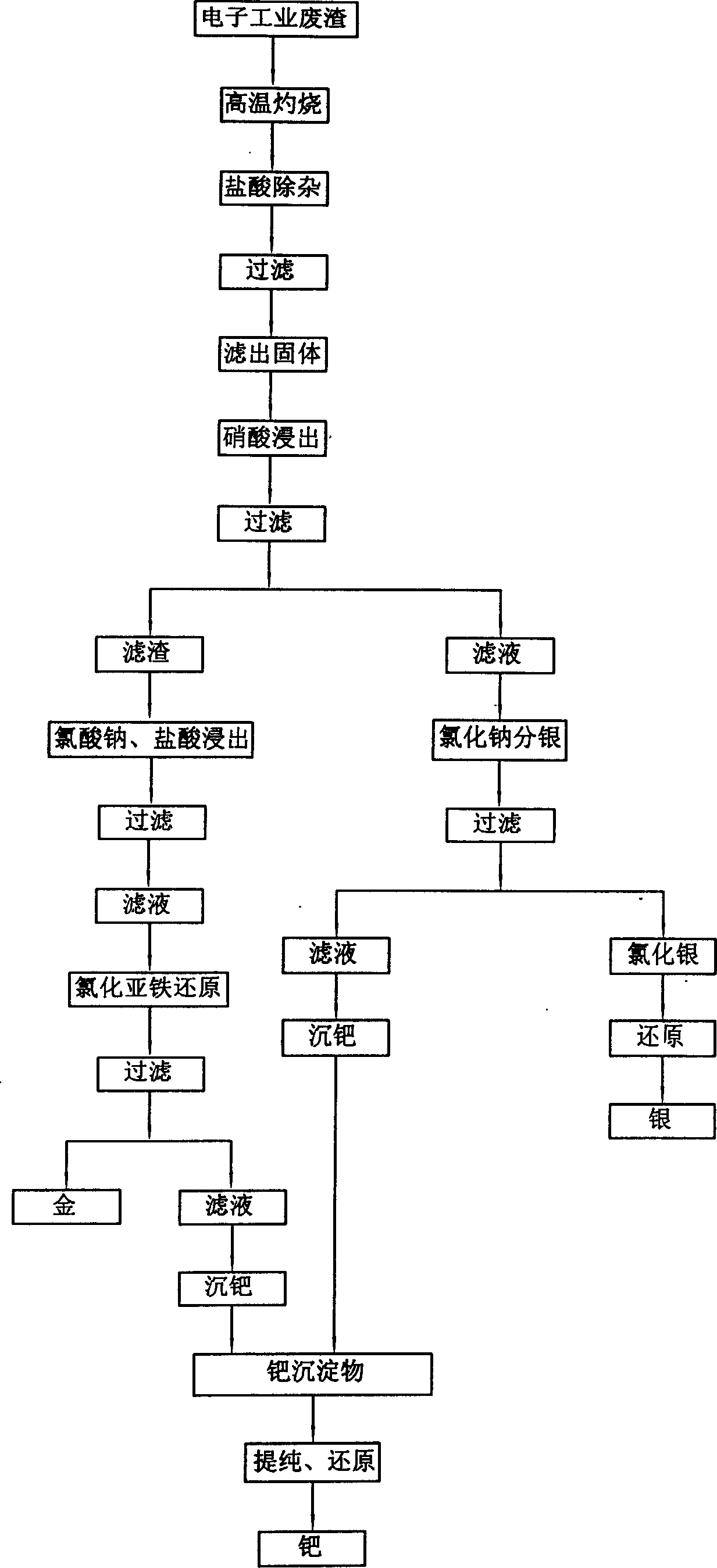

Technological process for extracting gold, silver and palladium from electronic industry waste

A process method, a technology of the electronics industry, applied in the direction of improving process efficiency, etc., can solve problems such as poor operating environment, and achieve high-efficiency extraction and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Dry the solid slag such as the solid slag produced by the display production line, the solid slag produced by the mobile phone, computer and other circuit board production lines at a temperature of 105 ° C, and crush it with a ball mill after drying, and sieve to remove impurities.

[0027] (2) Using an X-ray fluorescence spectrometer (XRF) to analyze the content of each element to determine the specific parameters of the process.

[0028] (3) The solid slag contains organic matter, and the organic matter will consume the oxidant during the extraction process and will adsorb precious metals, resulting in additional loss of precious metals. Therefore, the pulverized solid slag is burned in a muffle furnace, and the temperature is controlled between 450 and 500 ° C. Because the temperature is too low, the burning is not sufficient, and the temperature is too high, which will cause the metal palladium Pd to oxidize into palladium oxide PdO. Palladium oxide is difficult...

Embodiment 2

[0046] Other conditions remain unchanged, the firing temperature in the muffle furnace in (3) of Example 1 is controlled between 400-450° C., and the firing time can be about 11 hours.

Embodiment 3

[0048] With other conditions unchanged, the hydrochloric acid in (4) of Example 1 was replaced with sulfuric acid with a volume ratio of 1:6, and the weight ratio of sulfuric acid to solid slag was 5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com