Digital control correcting method for resonance frequency of piezoelectric transducer and supersonic concentrator

A piezoelectric transducer and resonant frequency technology, applied in the ultrasonic field, can solve the problems of high labor intensity, low production efficiency, and increased production cost, and achieve low labor intensity, high correction efficiency, and low correction cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

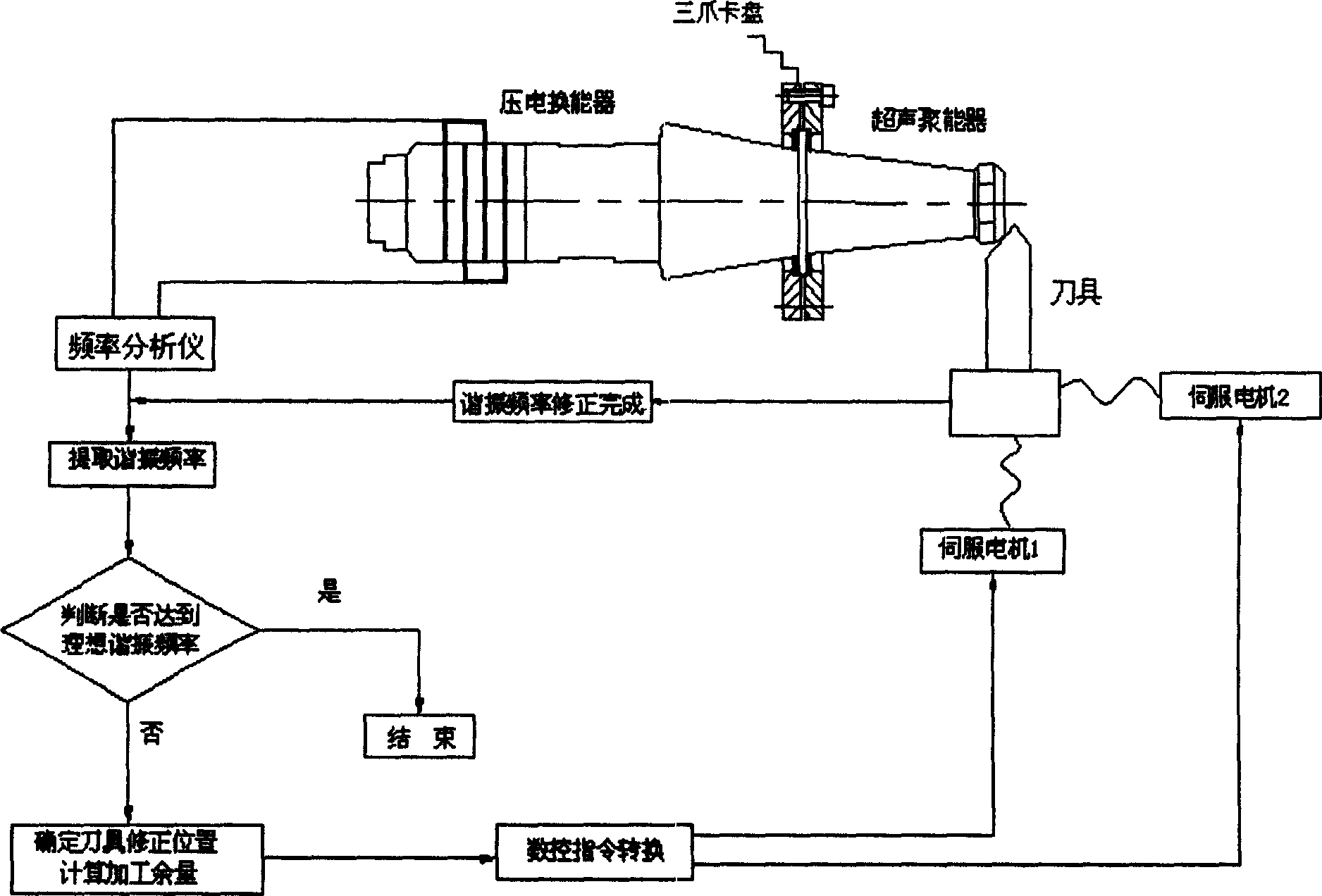

[0054]In the present invention, the piezoelectric transducer and the ultrasonic energy concentrator assembled together are installed on the three-jaw chuck or the special fixture of the numerically controlled lathe through the flange at the node of the ultrasonic energy concentrator. The positive and negative poles of the piezoelectric transducer are respectively connected to the positive and negative poles of the frequency (impedance) analyzer. While the piezoelectric transducer is rotating at high speed with the spindle of the CNC lathe, the frequency (impedance) analyzer measures the resonance frequency of the piezoelectric transducer and the ultrasonic concentrator in real time, and transmits the detected actual resonance frequency parameters to The computer calculates the difference between the actual resonance frequency and the theoretical resonance frequency, the correction position and correction margin of the piezoelectric transducer and the ultrasonic concentrator, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com