Method for locally shaping of glass sheet and glass sheet or glass ceramic sheet having locally deformed zone

A technology of glass ceramics and partial deformation, which is applied in glass forming, glass rolling, glass reshaping, etc. It can solve the problems of costly and time-consuming operation steps, and achieve the effect of saving energy and processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] According to the invention, it is possible in particular to provide a glass-ceramic plate for the cooking surface, which is designed upwards or downwards in the region of the cooktop level and which can be produced cost-effectively with a high degree of flexibility by combining the starting material, prefabricated glass blanks Thinning in the area to be deformed. This purposefully placed thinning of the material facilitates the deformation process by simple gravitational sinking during the thermal ceramization process.

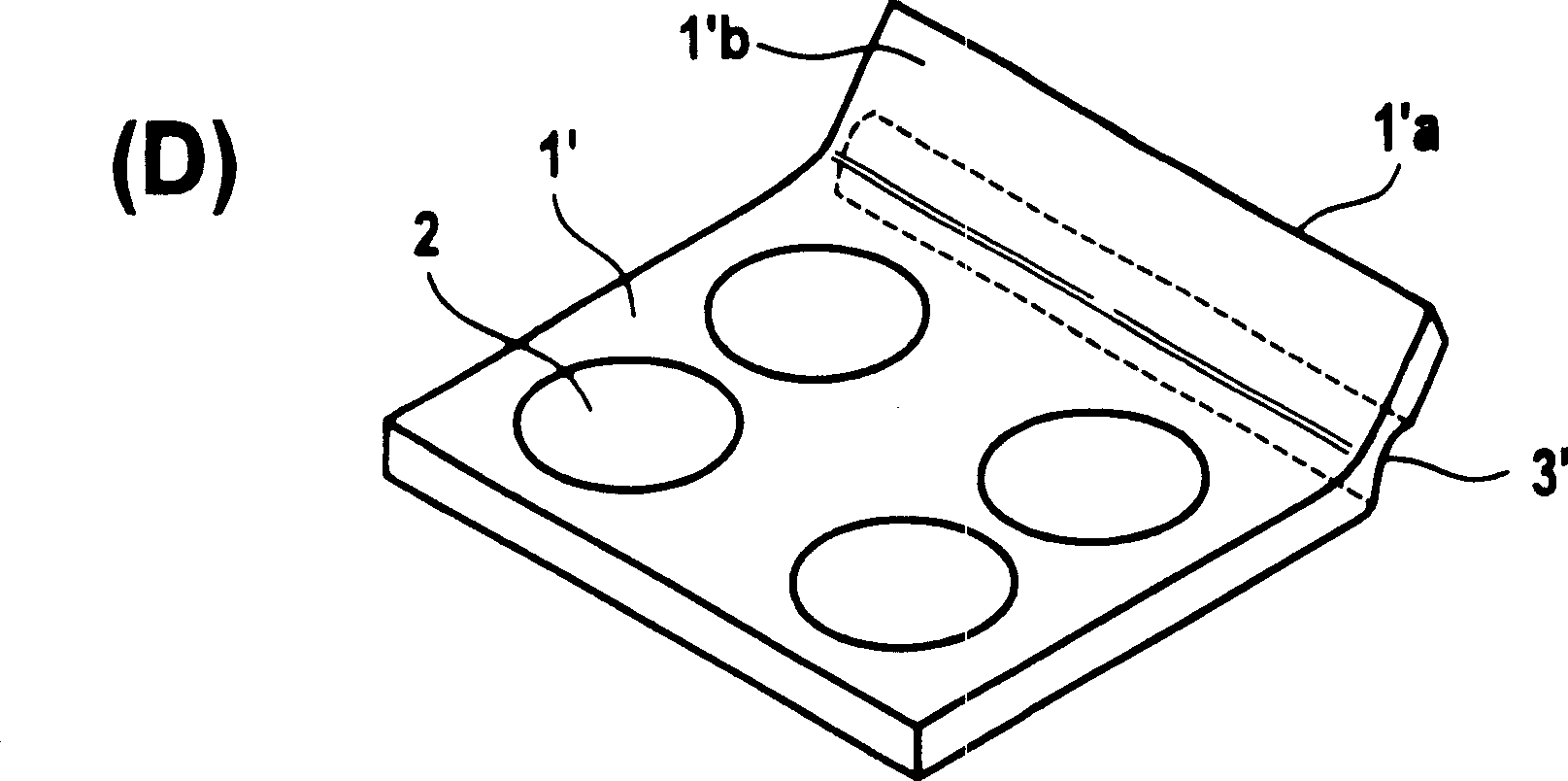

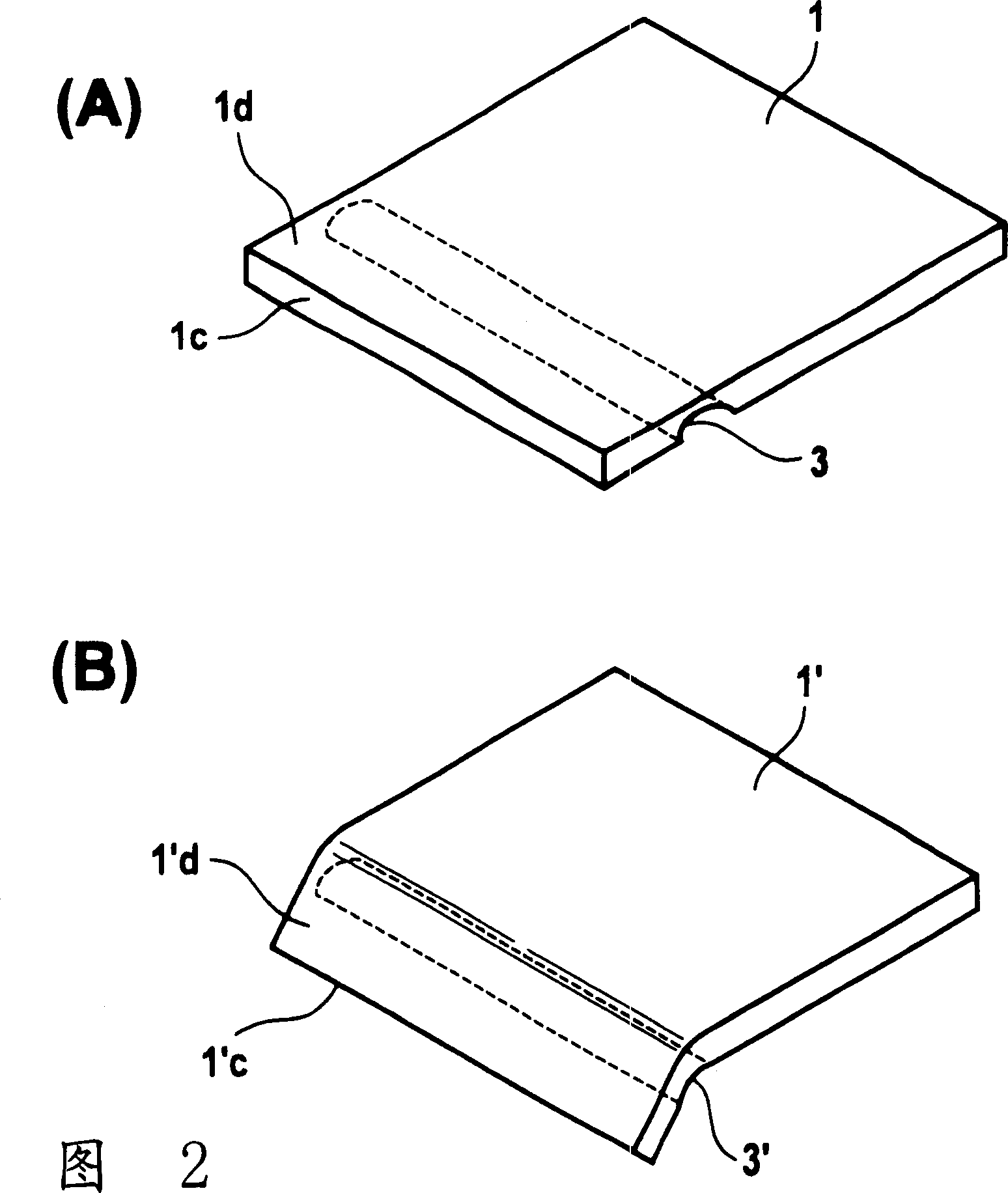

[0048] figure 1 An embodiment of the variant on a cooking panel is shown, where the rear end area is raised. Part A of the figure shows a prefabricated glass blank 1 with the cooking zone 2 shown. On the glass blank 1, a material thinning zone 3 is arranged in the rear end region 1b parallel to the rear edge 1a, preferably during the rolling process of the glass blank. In case the total thickness of the sheet is in the range of 4-6 mm, the remaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com