Whole sealing oil pump for transformer

A transformer oil, fully-sealed technology, applied in the field of transformer oil pumps, can solve the problems affecting the smooth operation of the transformer, the hidden danger of oil leakage of the pump body and the base, etc., so as to solve the problem of oil leakage of the oil pump, improve the service life, and eliminate the hidden danger of oil leakage of the oil pump. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

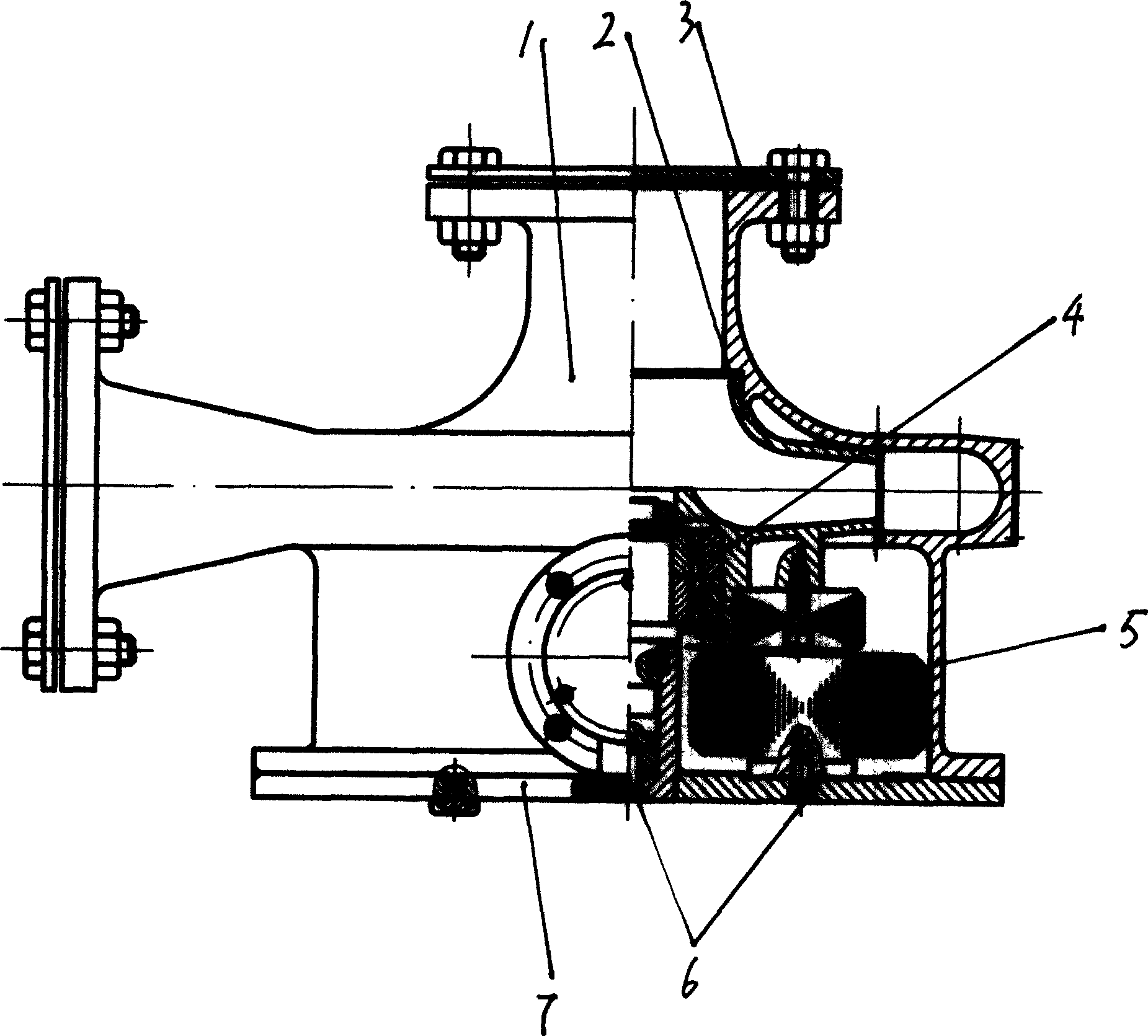

[0007] As shown in the figure, the transformer oil pump mainly includes pump body 1, impeller 2, plug cover 3, motor 5, base 7, junction box and sealing connector, etc. The paired thrust bearing 4 is welded and sealed between the oil pump housing 1 and the cover 3, and between the base 7 and the pump body 1, and the joints fixed with screws 6 at the bottom of the pump body are all welded and closed after installation. Grinding, so that the entire pump body is in a fully sealed state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com