Dual water phase extracting system and process for separating and purifying alpha-amylase inhibitor by said system

An amylase inhibitor and two-phase water-phase technology, which is applied in the field of separation and purification of protein bioactive target products, can solve the problems that are not conducive to industrial scale-up application, long operation cycle, high cost, etc., to shorten the process operation cycle, save dosage, The effect of maintaining biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Crude extraction of α-amylase inhibitors:

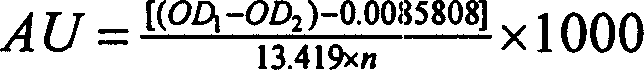

[0028] ●Weigh 4kg of flour, add 16L, 0.1mol / L NaCl solution, put it in a stirring tank with a rotation speed of 100rpm / min and stir and extract for 3 hours. The concentration is 3.543mg / ml, the inhibitory activity is 103.4AU, and the specific activity is 29.18.

[0029]The centrifuged supernatant was concentrated to a volume of 2.5 liters with an ultrafiltration membrane with a cut-off molecular weight of 6000, the measured protein concentration was 17.76 mg / ml, the inhibitory activity was 538.4 AU, the calculated specific activity was 30.3, and the ultrafiltration concentrate was 25% The saturated ammonium sulfate was salted out and centrifuged to obtain a solid, then dissolved with 0.1mol / ml phosphate buffer and centrifuged again to obtain 1L of supernatant, the measured protein concentration was 12.88mg / ml, the inhibitory activity was 1218.9AU, and the specific activity was calculated as 94.6,.

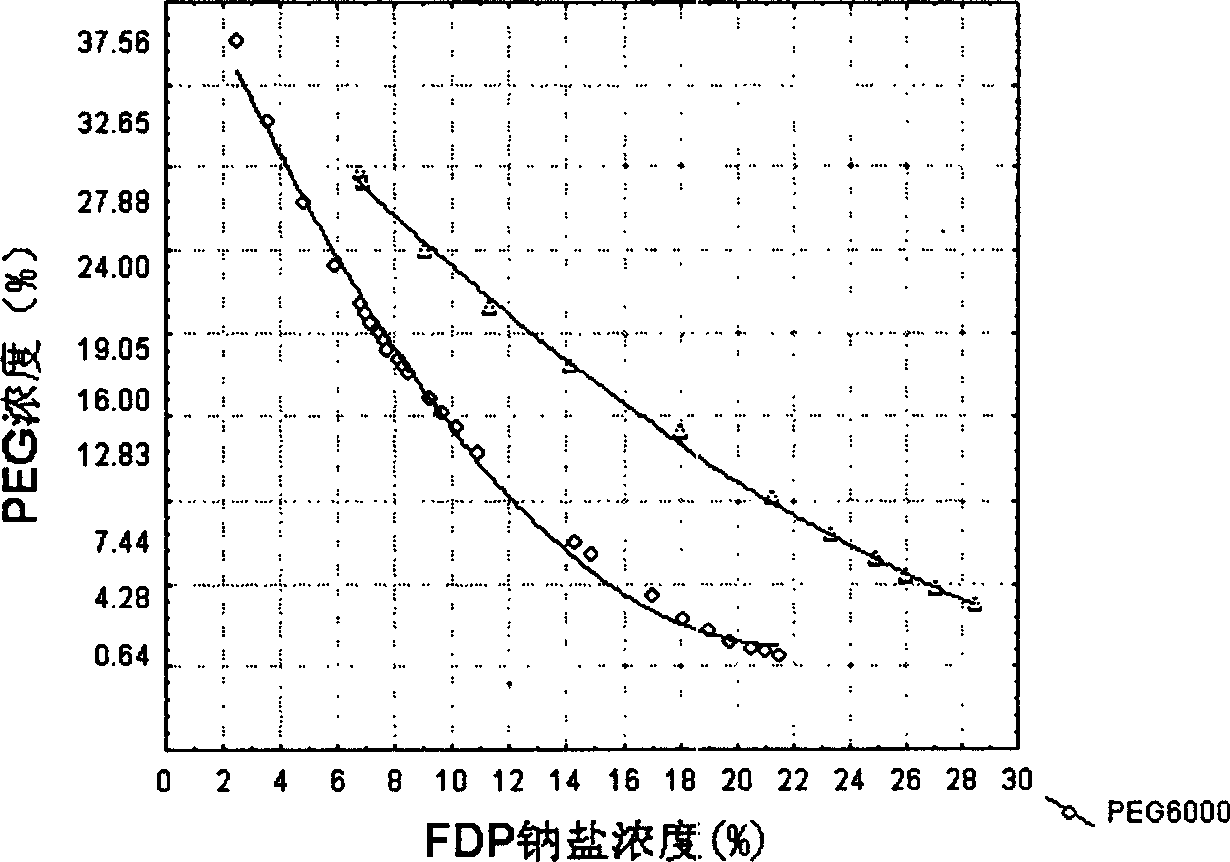

[0030] 2. Polyethylene...

Embodiment 2

[0078] 1. Crude extraction of α-amylase inhibitor: as in Example 1.

[0079] 2. Polyethylene glycol / fructose-1,6-diphosphate magnesium salt two-phase system separation and extraction of α-amylase inhibitors

[0080] The crude clear solution of α-amylase inhibitor is desalinated with an ultrafiltration membrane with a molecular weight cut-off of 6000, and concentrated to a volume of 405ml, and the pH of the concentrated solution is adjusted to between 4 and 5, and the protein concentration at this time is measured as 27mg / ml, the inhibitory activity is 2750.8AU, and the calculated specific activity is 101.

[0081] In a 1L separating funnel, add 114g of polyethylene glycol with a molecular weight of 6000, 340g of magnesium fructose-1,6-diphosphate, and 405ml of concentrated solution, shake and mix well, and let stand for 10 minutes to complete the phase formation. Emit the lower phase solution from the bottom to obtain the upper phase solution with a volume of 118ml. The prote...

Embodiment 3

[0085] 1. Crude extraction of α-amylase inhibitor: as in Example 1.

[0086] 2. Polyethylene glycol / fructose-1,6-diphosphate potassium salt two-phase system separation and extraction of α-amylase inhibitors

[0087] The crude clear solution of α-amylase inhibitor is desalinated with an ultrafiltration membrane with a molecular weight cut-off of 6000, and concentrated to a volume of 420ml, and the pH of the concentrated solution is adjusted to between 4 and 5, and the protein concentration at this time is measured as 30mg / ml, the inhibitory activity is 2830.8AU, and the calculated specific activity is 94.4.

[0088] In a 1L separating funnel, add 120g of polyethylene glycol with a molecular weight of 6000, 360g of fructose-1,6-diphosphate potassium salt, and 420ml of concentrated solution, shake and mix well, and let stand for 10 minutes to complete the phase formation. Emit the lower phase solution from the bottom to obtain the upper phase solution with a volume of 140ml. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com