Preparation method low electric conductiving super fine aluminium hydroxide micro powder

An ultra-fine aluminum hydroxide, low conductivity technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve problems such as poor dispersion, increased material viscosity, electrical breakdown, etc. Achieve the effect of broadening the application field, improving the processing performance, and improving the electrostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

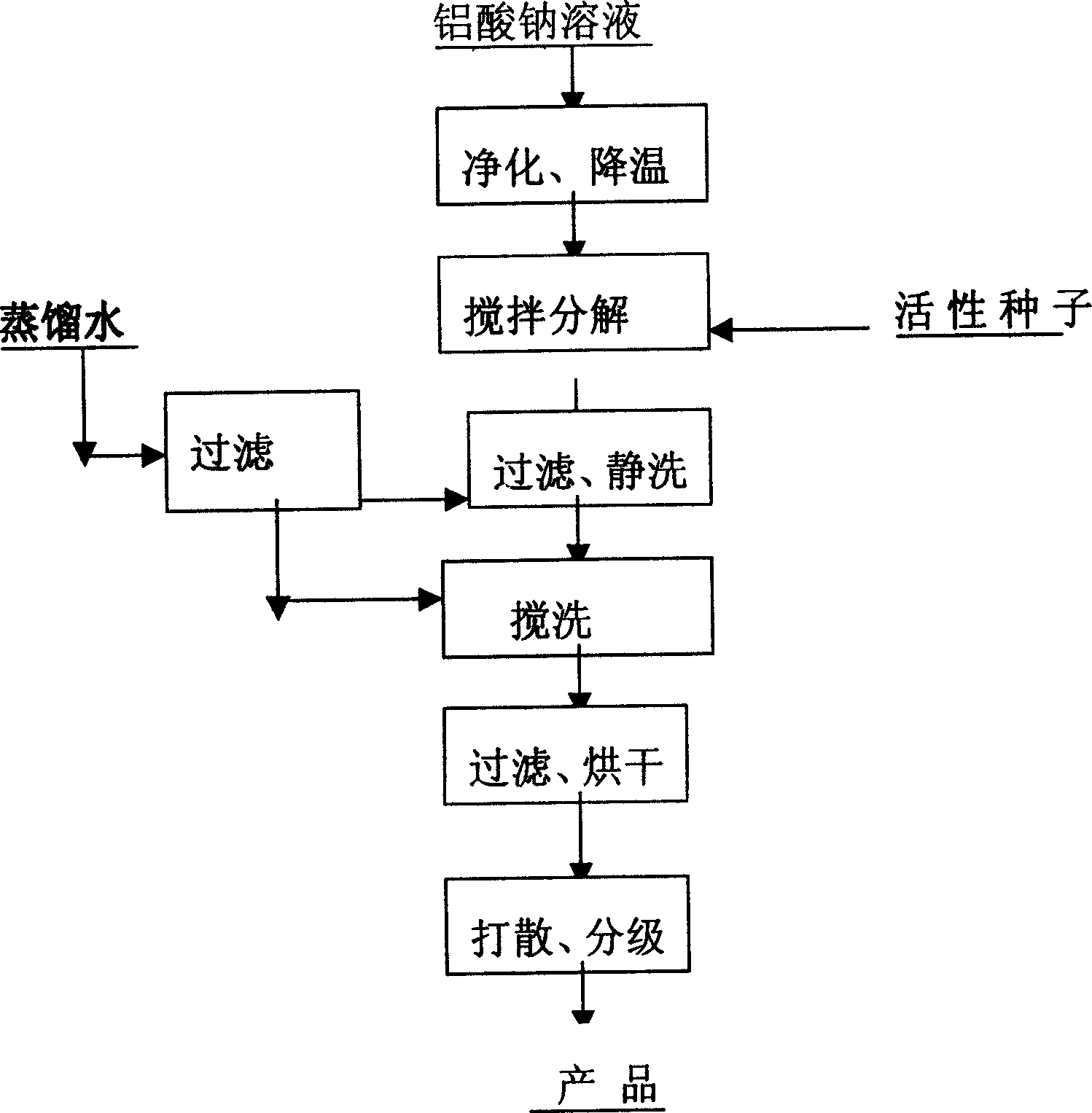

Method used

Image

Examples

Embodiment 1

[0017] The sodium aluminate solution is desiliconized and purified, the silicon content index is 700, and the float is 0.02%. At a temperature of 54°C, add mechanically ground active seeds with a seed coefficient of 10%, and control the temperature at 55°C. Decompose, wash after decomposing for 3 hours, wash with distilled water until the total alkali concentration NaO is 0.05g / L, filter until the water content of the filter cake is 30%, and then carry out intensive drying, breaking up and grading. The obtained product is ultrafine aluminum hydroxide micropowder with a D50 of 0.5-0.7 μm in the crystal form of α-gibbsite, and a resistivity of 140 μS / cm.

Embodiment 2

[0019] The sodium aluminate solution is desiliconized and purified, the silicon content index is 650, and the float is 0.02%. At a temperature of 61°C, add mechanically ground active seeds with a seed crystal coefficient of 4%, and control the temperature at 61°C. Decompose, wash after decomposing for 5 hours, wash with distilled water until the total alkali concentration NaO is 0.05g / L, filter until the water content of the filter cake is 25%, and then carry out intensive drying, breaking up and grading. The obtained product is ultrafine aluminum hydroxide micropowder with a D50 of 0.7-1.0 μm in the crystal form of α-gibbsite, and a resistivity of 110 μS / cm.

Embodiment 3

[0021] The sodium aluminate solution is desiliconized and purified, the silicon content index is 640, and the floating matter is 0.02%. At a temperature of 68°C, add mechanically ground active seeds with a seed crystal coefficient of 12%, and control the temperature at 68°C. Decompose, wash after decomposing for 6 hours, wash with distilled water until the total alkali concentration NaO is 0.05g / L, filter until the water content of the filter cake is 24%, and then carry out intensive drying, breaking up and grading. The obtained product is ultrafine aluminum hydroxide micropowder with a D50 of 1.2-1.8 μm in the crystal form of α-gibbsite, and a resistivity of 90 μS / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com