High-frequency throwing structure

A wire structure, high-frequency technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as difficulty in implementation, counter-effects, contact between two dozen wires, etc., to achieve the best electrical characteristics, best capacitance and inductance matching, avoid The effect of too close between lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

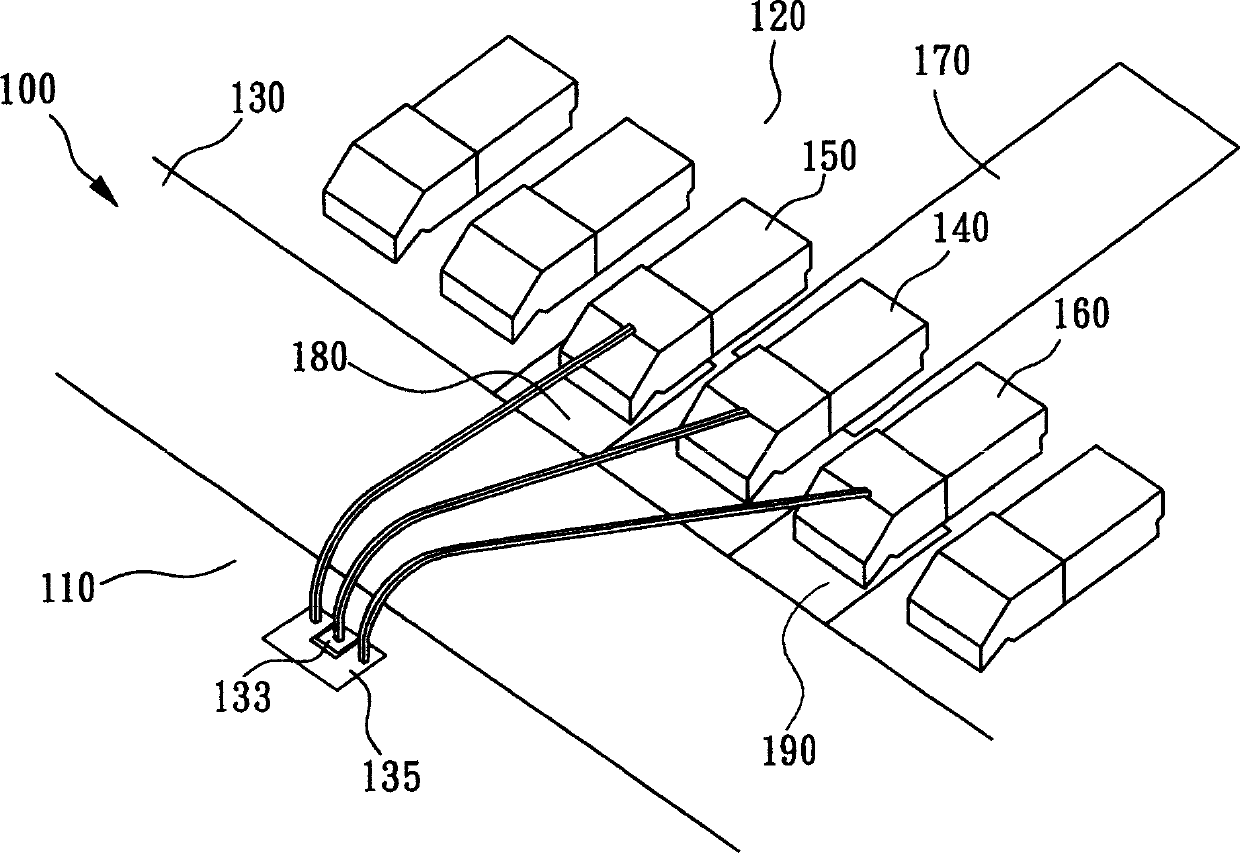

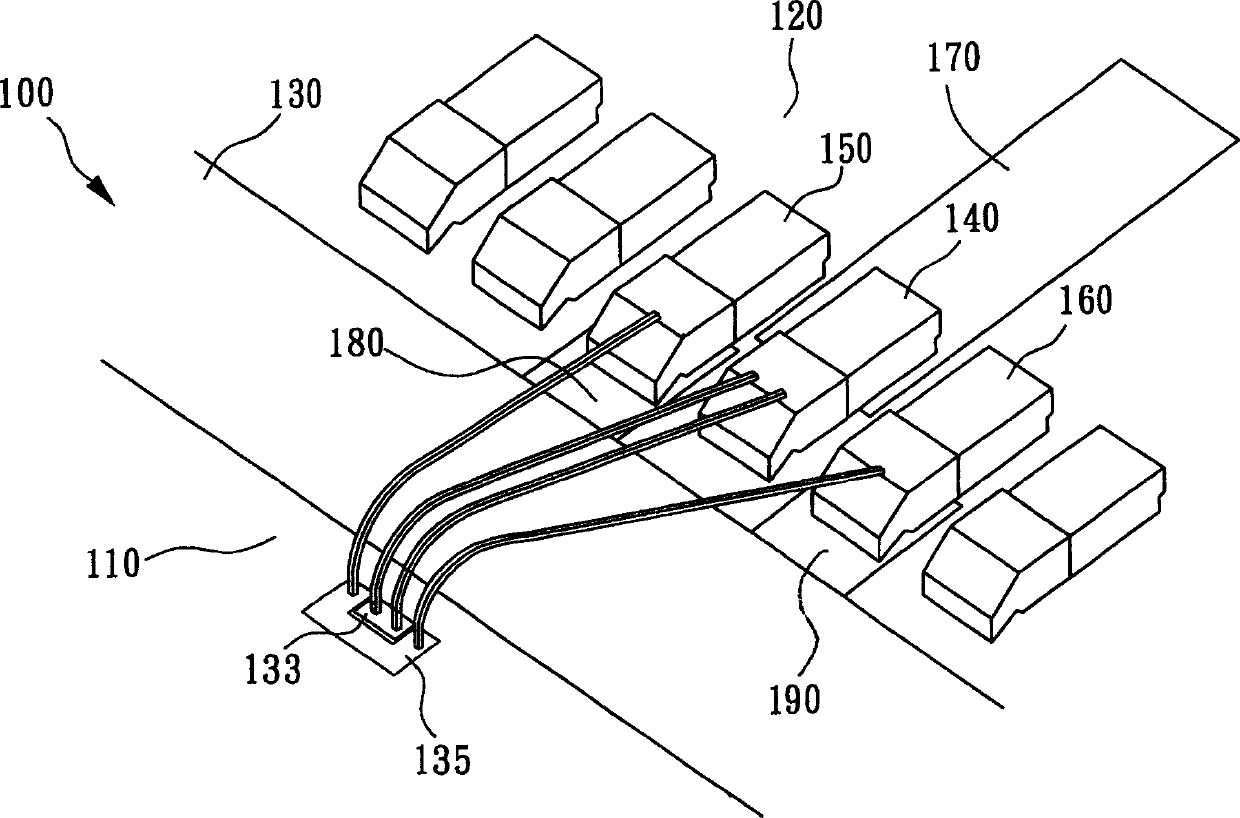

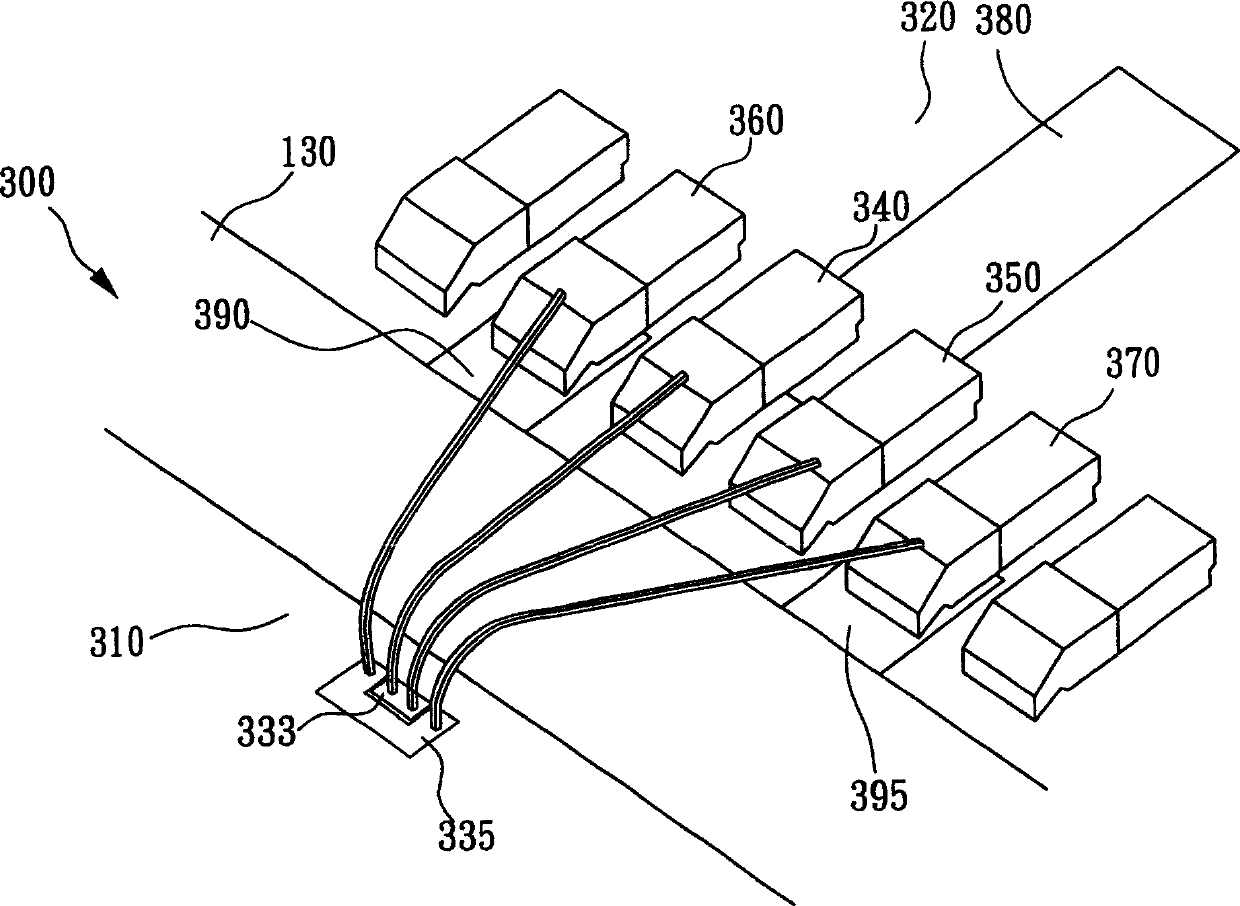

[0040] In order to make the characteristics, purpose and functions of the present invention be further recognized and understood, the detailed description is as follows in conjunction with the accompanying drawings:

[0041] The present invention is based on the high-frequency bonding structure generally used in radio frequency or high-speed circuits. In order to make the electrical characteristics between the chip and the package better, the signals are usually output in parallel, and the two adjacent sides of the signals are respectively Ground loop, so the bonding between the chip and the package is very dense. Therefore, it is difficult to implement wire bonding, and it is easy to cause contact between wires in the future when the adhesive film is applied, thereby greatly reducing the electrical characteristics between the chip and the package.

[0042] Therefore, the present invention considers that in addition to outputting the high-frequency signal bonding pads at the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com