Ion generating apparatus

An ion generating device, ion generator technology, applied in the chemical/physical/physical chemical process of applying energy, ozone preparation and other directions, can solve the problems of dangerous accidents, ion generator failure, easy to be broken down, etc., to avoid danger effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

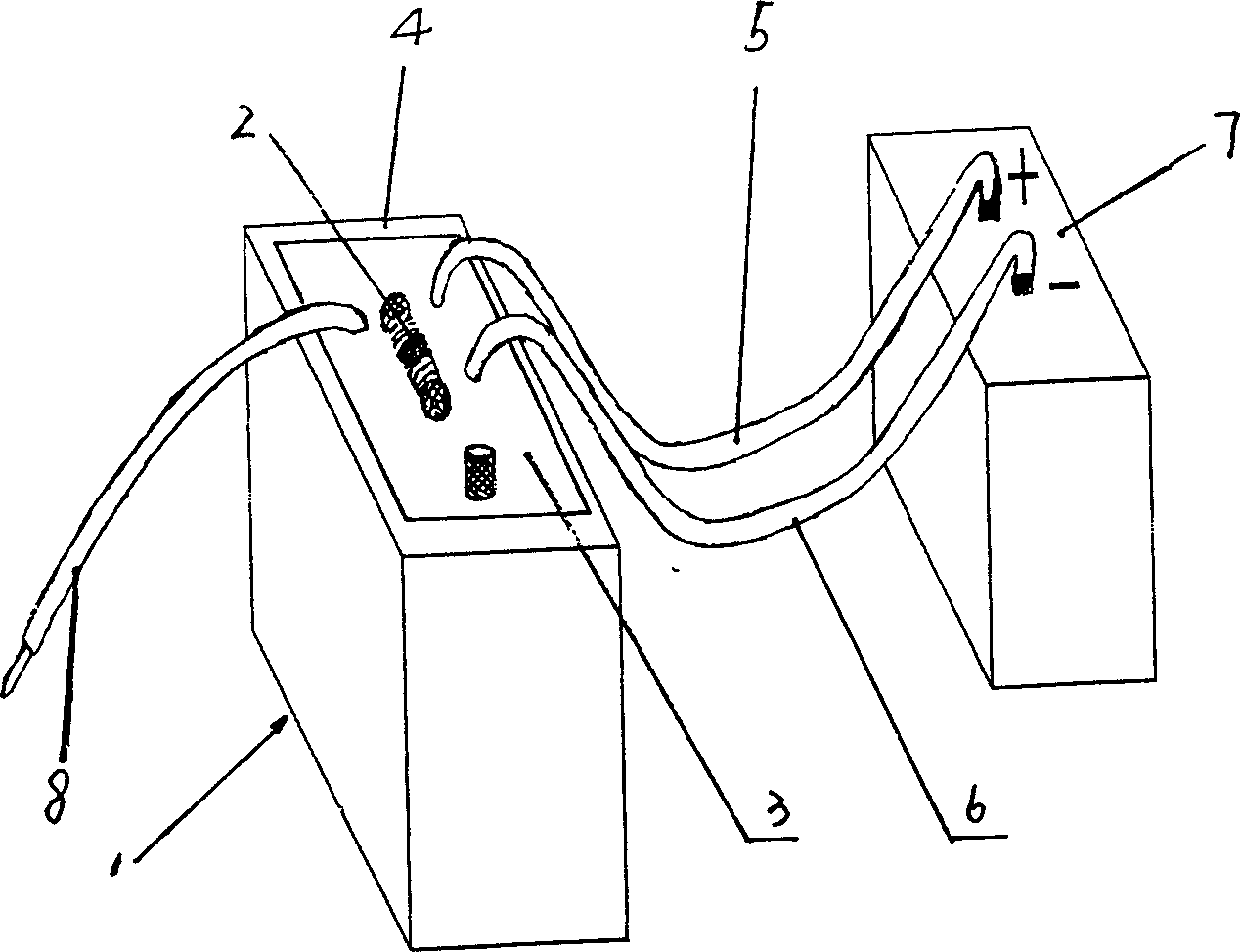

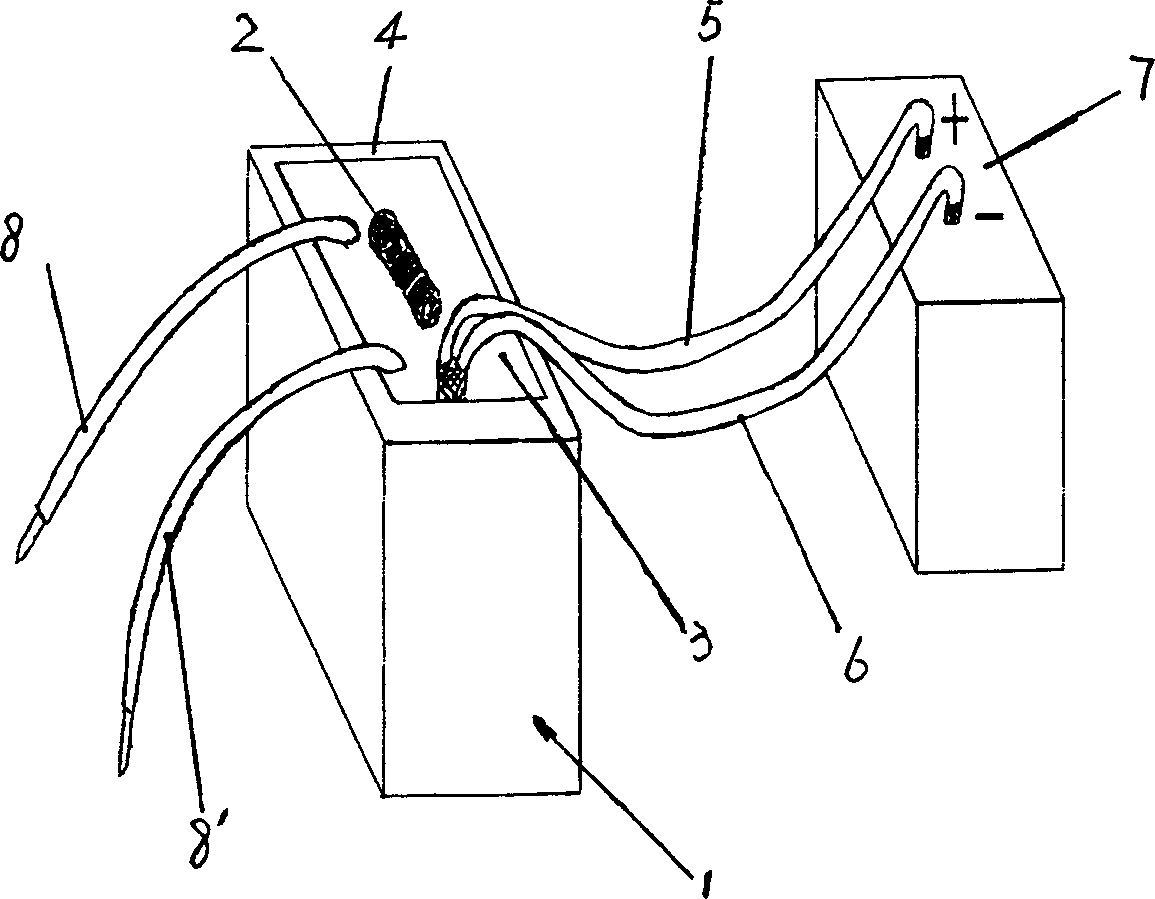

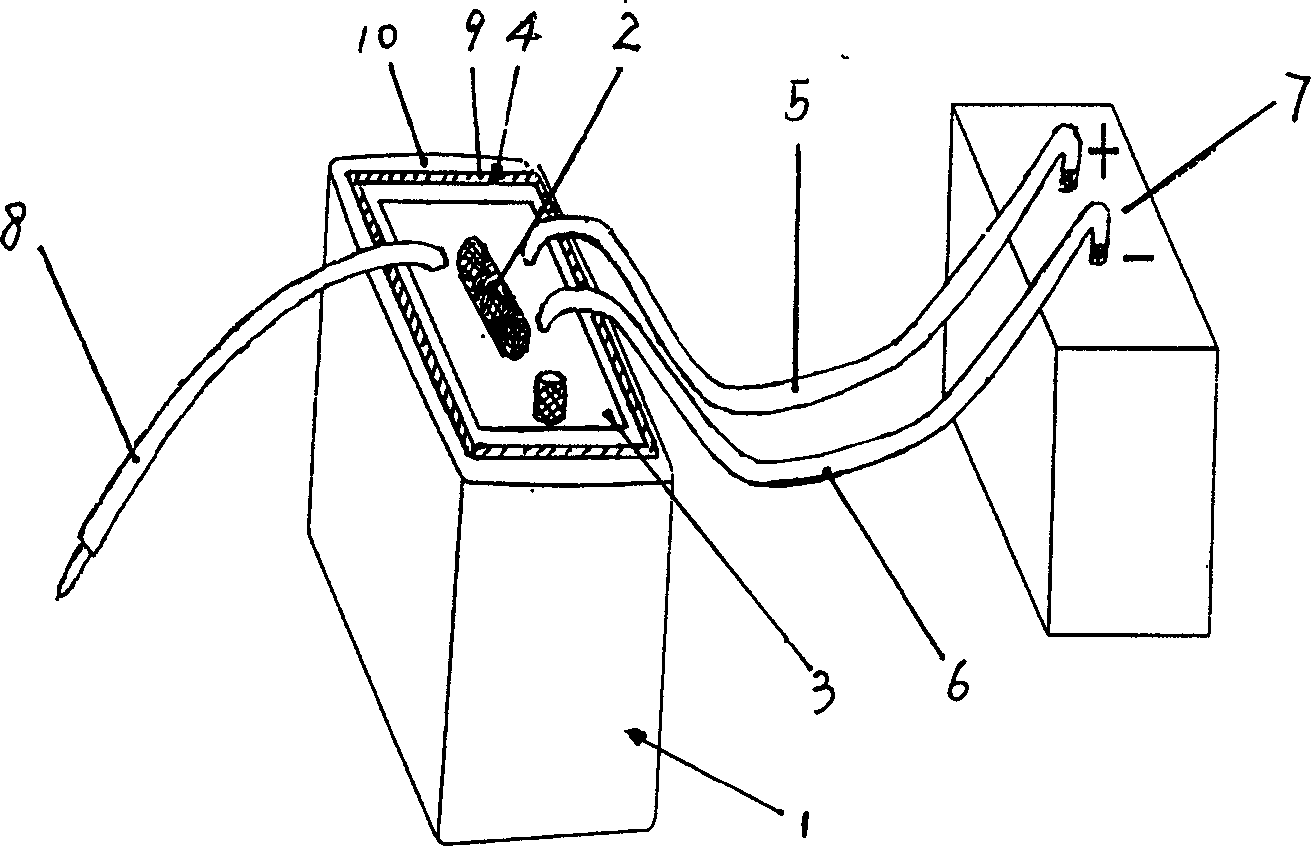

[0010] See attached figure 1 - attached image 3 , an ion generating device, comprising an ion generator 1, a power supply 7, the ion generator 1 is electrically connected to the power supply 7 through a power line 5 and a power line 6, and the ion generator 1 has a high-voltage discharge wire drawn out 8. The ion generator 1 includes a shell, an oscillating high voltage generator 2 arranged in the inner cavity of the shell, and at least one layer of the shell is a high-voltage shell 4 .

[0011] See attached figure 1 , the high-voltage housing 4 is made of high-voltage ceramic material. The ceramic material can withstand both high pressure and high temperature. For the ion generator 1 with higher power, the high voltage output up to 7.5kv will not break down the high voltage resistant shell 4, and the resulting high temperature is also due to The protection of the pressure-resistant shell 4 cannot damage the ion generator. See attached image 3 , in order to protect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com