Controlling nozzle touch force

A control system and nozzle technology, applied in the field of nozzle contact force control system, can solve problems such as increasing nozzle contact force, reducing mold life, and deteriorating molded product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

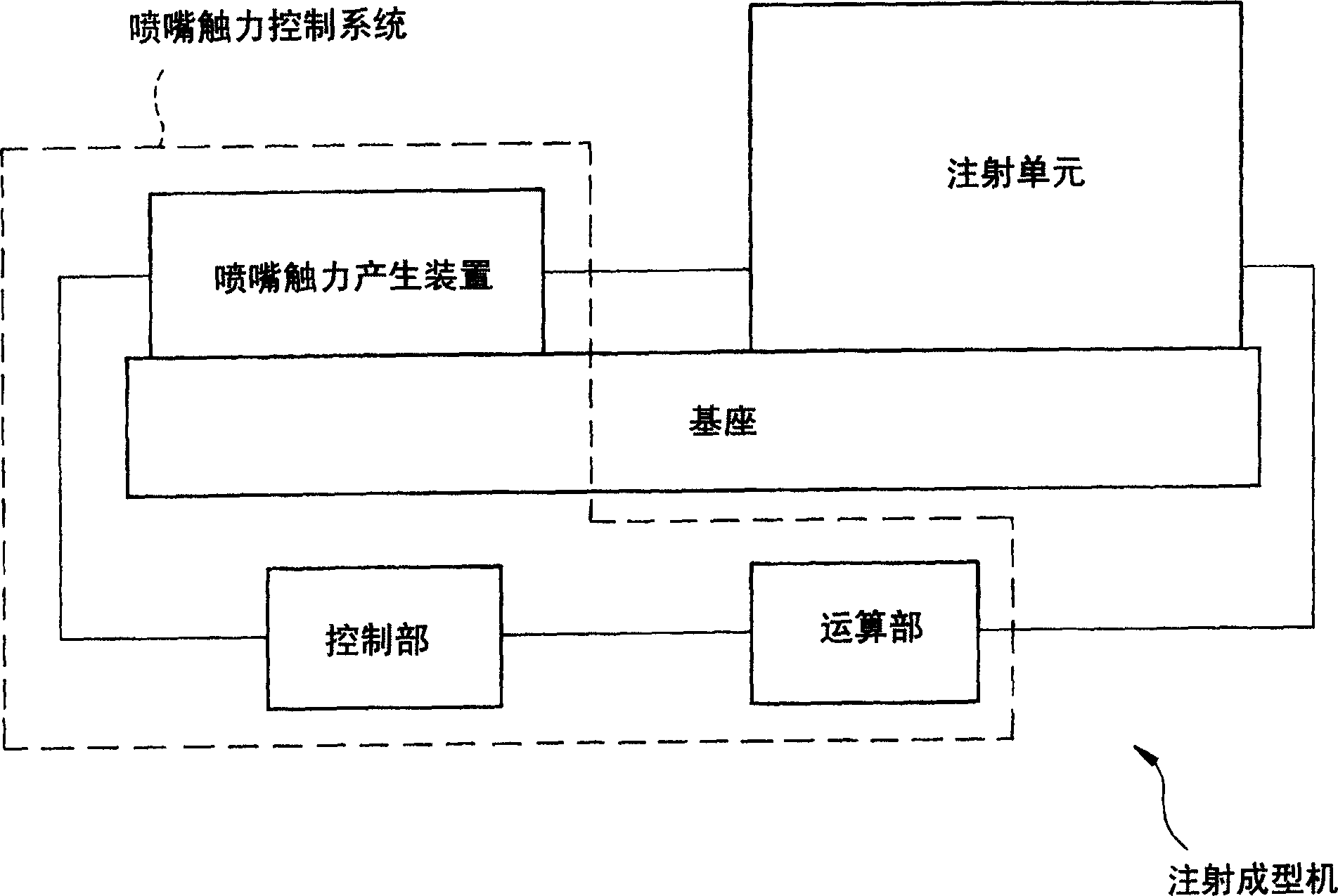

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

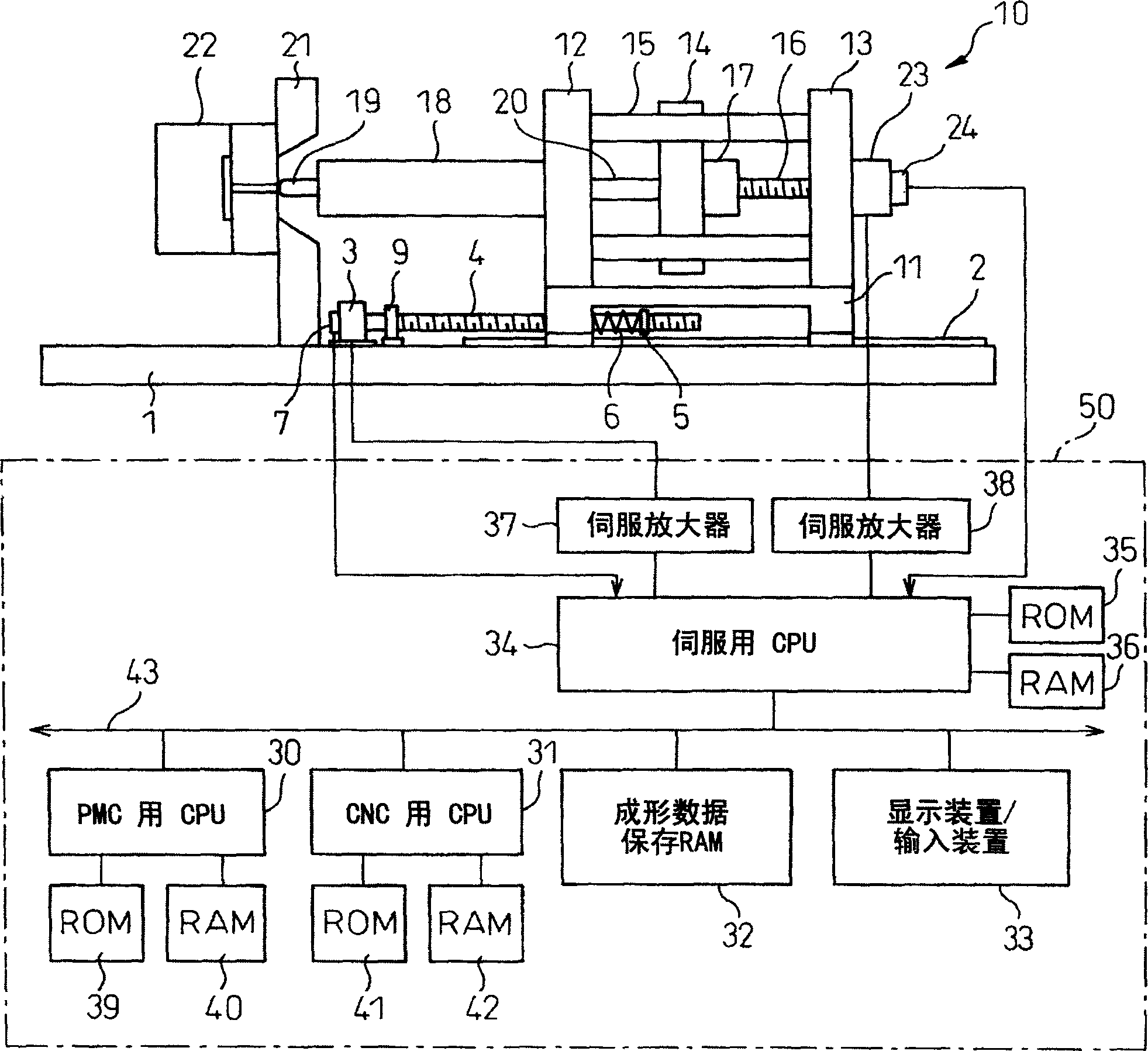

Embodiment Construction

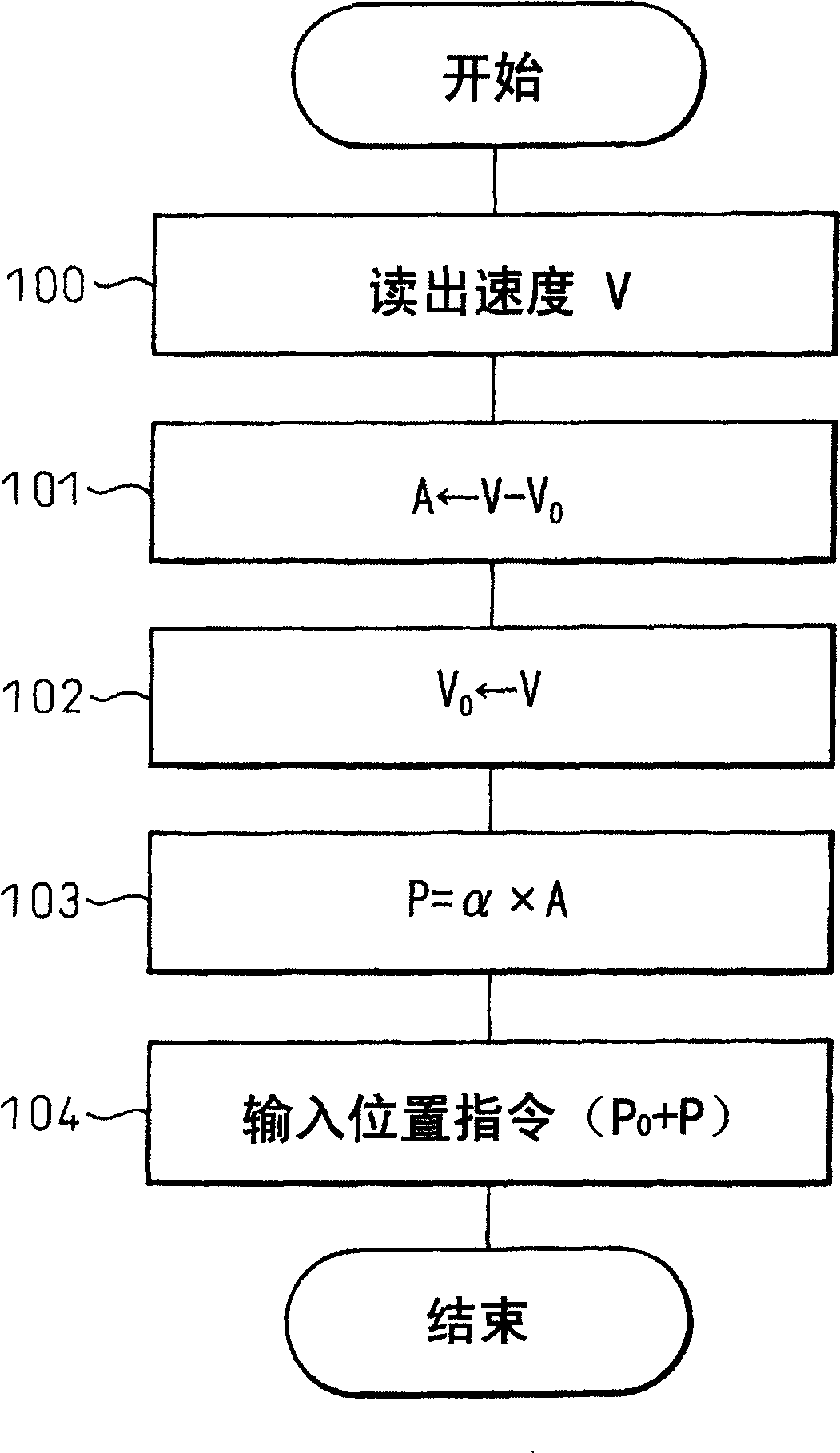

[0028] The present invention is to remove the influence of the inertial force of the movable part during the injection acceleration and deceleration during the injection, to always keep the nozzle contact force constant, to obtain the acceleration during injection (injection spiral acceleration), and to obtain the nozzle contact force based on this acceleration. The influence that controls the force generated by the nozzle contact force generating device. During injection, the molten resin is injected by movable parts such as injection screw or push plate, and it accelerates and decelerates. The inertial force is obtained by multiplying the acceleration during acceleration and deceleration by the mass of the movable part to be accelerated and decelerated. Therefore, the force that influences the nozzle contact force can be obtained by multiplying the acceleration during injection with a predetermined constant. In the present invention, the inertial force accompanying the accel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com