Preparation of bimetal cyanide catalyst using acid treating metal salt

A technology of double metal cyanide and metal salt, which is applied in the field of acid treatment of metal salt to prepare double metal cyanide complex catalyst, can solve problems such as harm and does not involve downstream polyurethane products and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

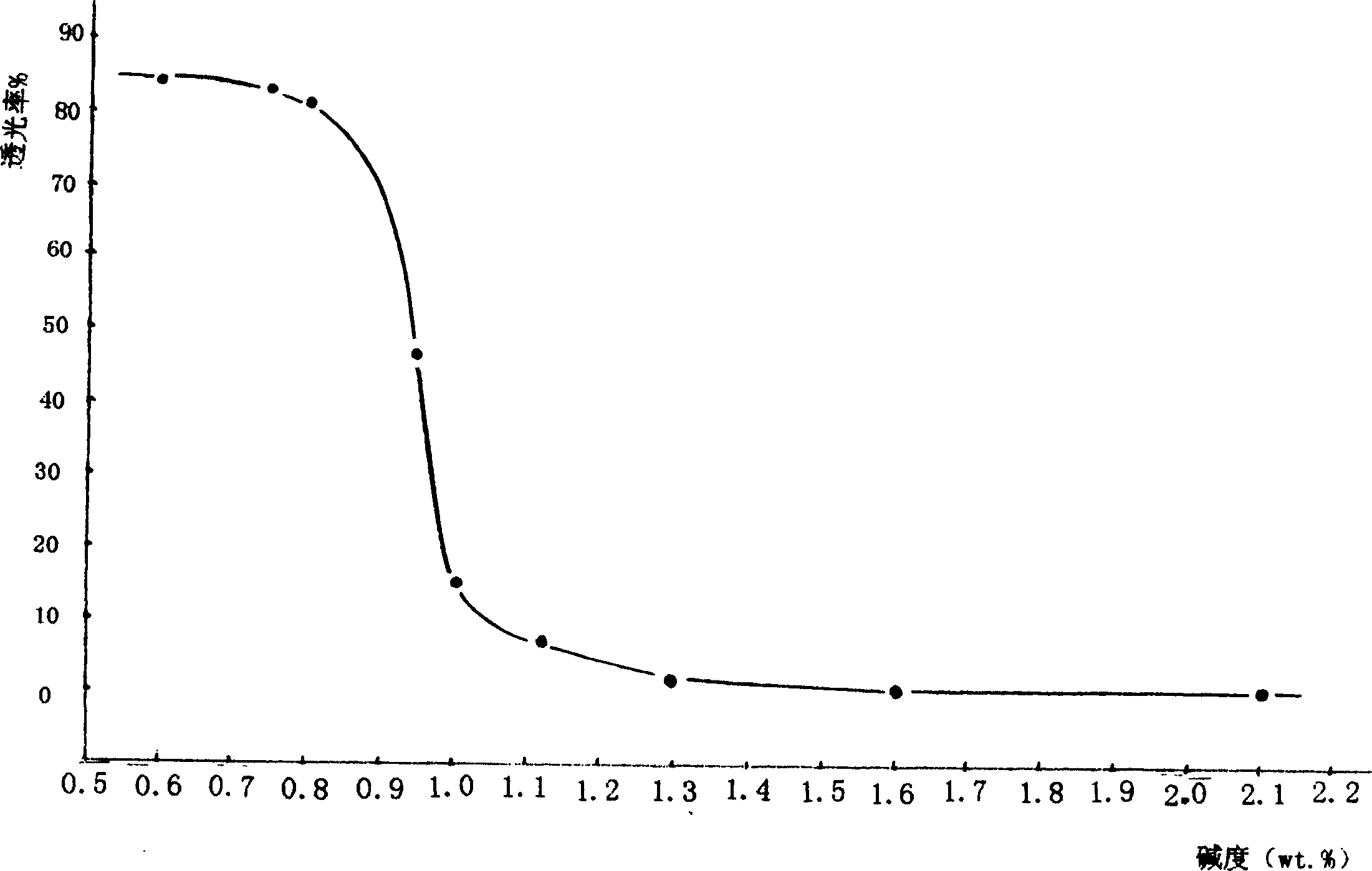

[0042] Take industrial product ZnCl 2 330.1 grams, add 180.2 grams of deionized water, stir to dissolve, and make ZnCl 2 The aqueous solution was filtered to remove solid impurities, and its concentration was analyzed to be 63.40wt.%. Take the ZnCl 2 8.071 grams of aqueous solution, carry out potentiometric titration with 0.1N hydrochloric acid, use graph method to obtain equivalence point (PH=3.7), use the volume of dehydrochloric acid to be 23.60ml, measure its alkalinity value to be 1.88wt.%, this value On the high side and needs adjustment.

[0043] After setting the adjusted ZnCl 2 The alkalinity value of the aqueous solution is 0.60 wt.%. Take 450.5 grams of this solution, and calculate according to formula-1 that 9.40 ml of hydrochloric acid with a concentration of 9.6N needs to be added. Slowly add hydrochloric acid to the ZnCl with stirring 2 In the aqueous solution, stir evenly for 3 to 5 minutes after adding, take a sample and analyze the alkalinity to be 0.5...

example 2~4

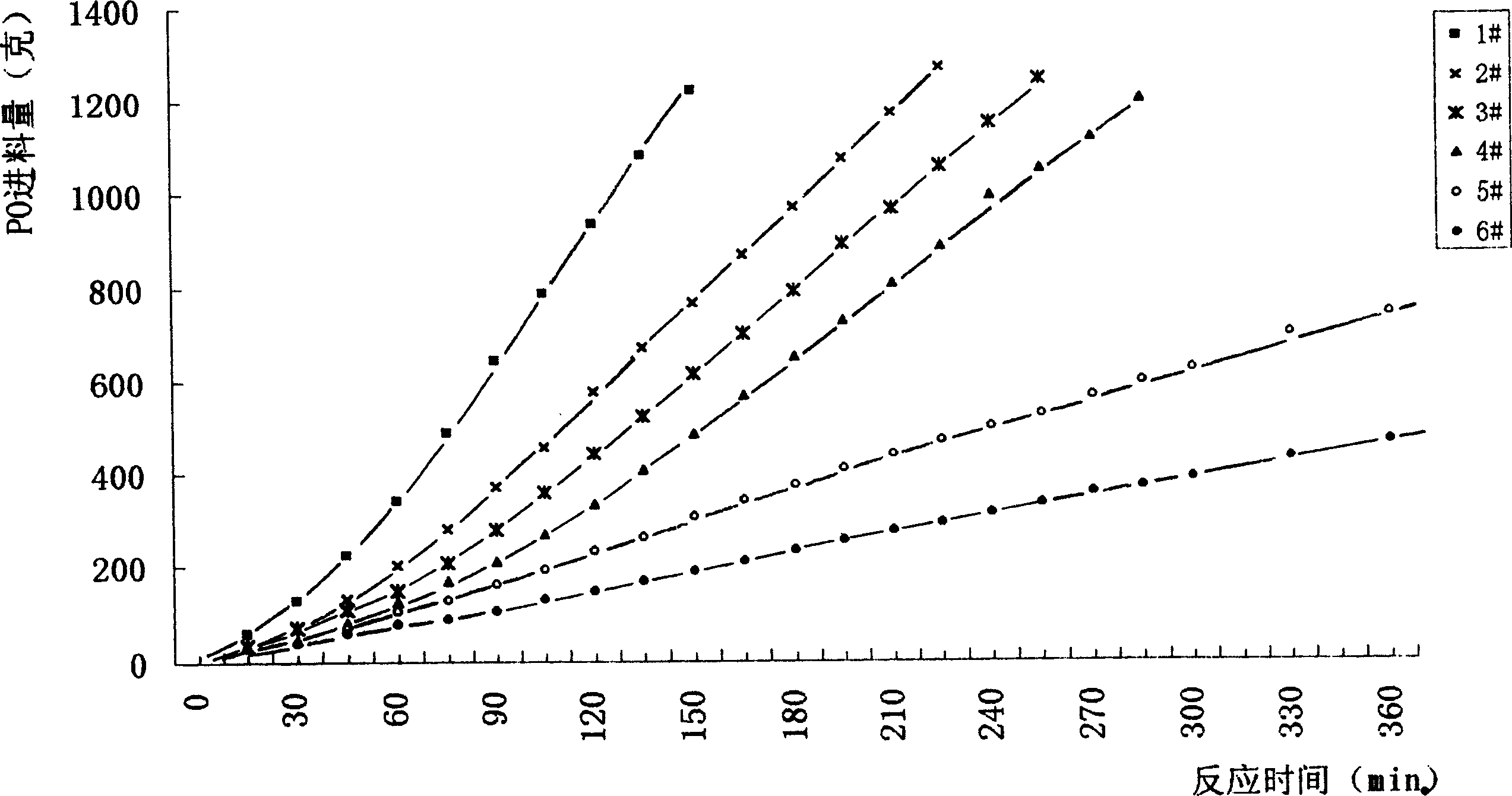

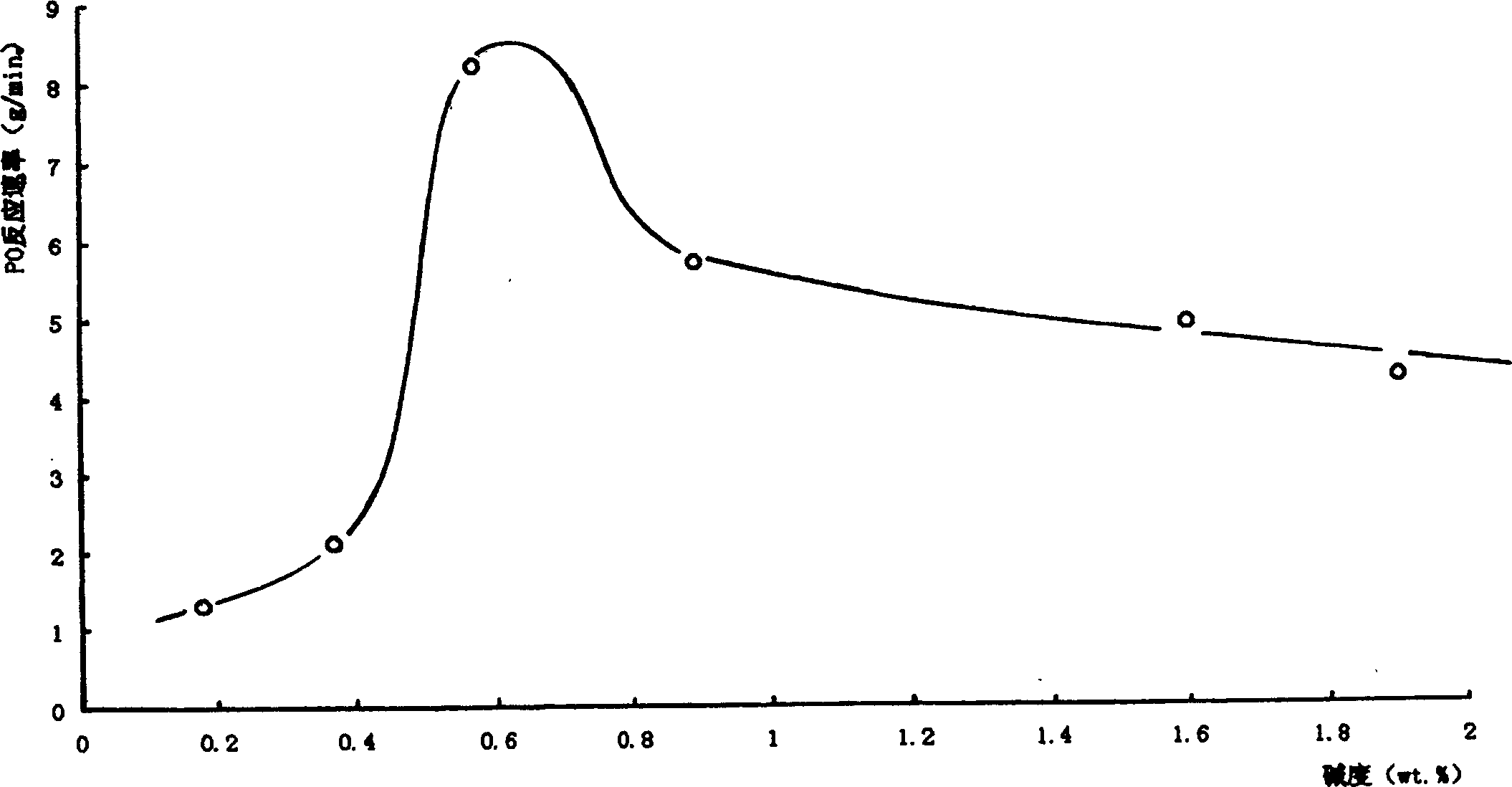

[0046] The method preparation concentration by example 1 is that 62.3wt.% alkalinity 0.89wt.%, concentration are three kinds of ZnCl that 60.9wt.% alkalinity 1.6wt.% and concentration are 61.3wt.% alkalinity 1.9wt.% 2 aqueous solution. Prepare DMC-2 with the technique that example 1 adopts # 、3 # 、4 # catalyst. In the process of preparing the DMC catalyst, use the above three kinds of ZnCl with high basicity 2 When the aqueous solution is mixed with water and tert-butanol to prepare the reaction raw material liquid, different degrees of white precipitates are produced. with DMC-2 # 、3 # 、4 # Catalyst synthesis of PPG-3000, the method is the same as Example 1, the reaction data of PO are listed in Table-4, the catalyst activation time and the performance of the synthesized PPG-3000 are listed in Table-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com