Electromagnetic plunge pump

A technology of electromagnetic plunger and plug pumps, which is applied in the direction of pumps, liquid variable displacement machines, engine components, etc., and can solve problems such as low oil supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

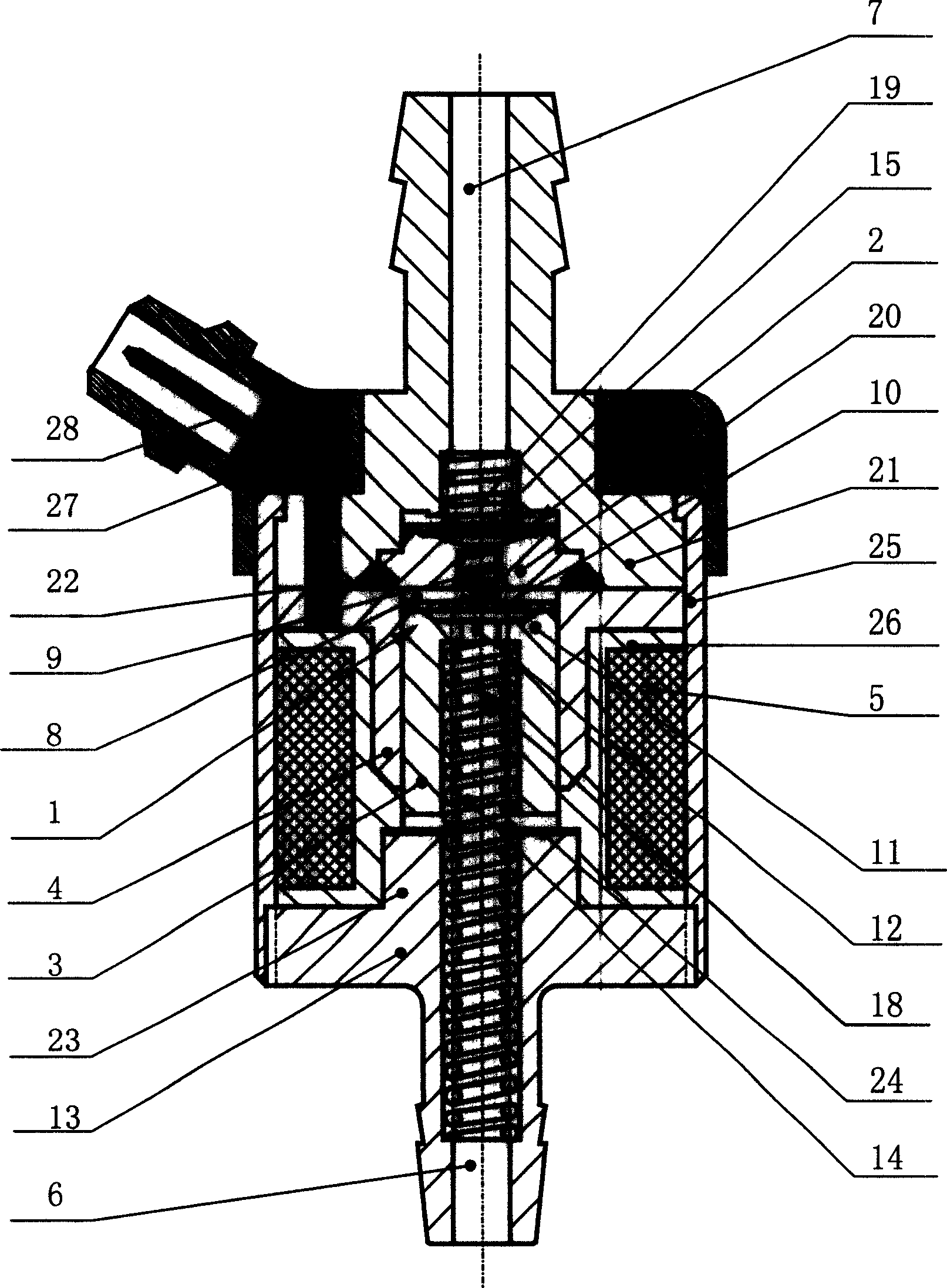

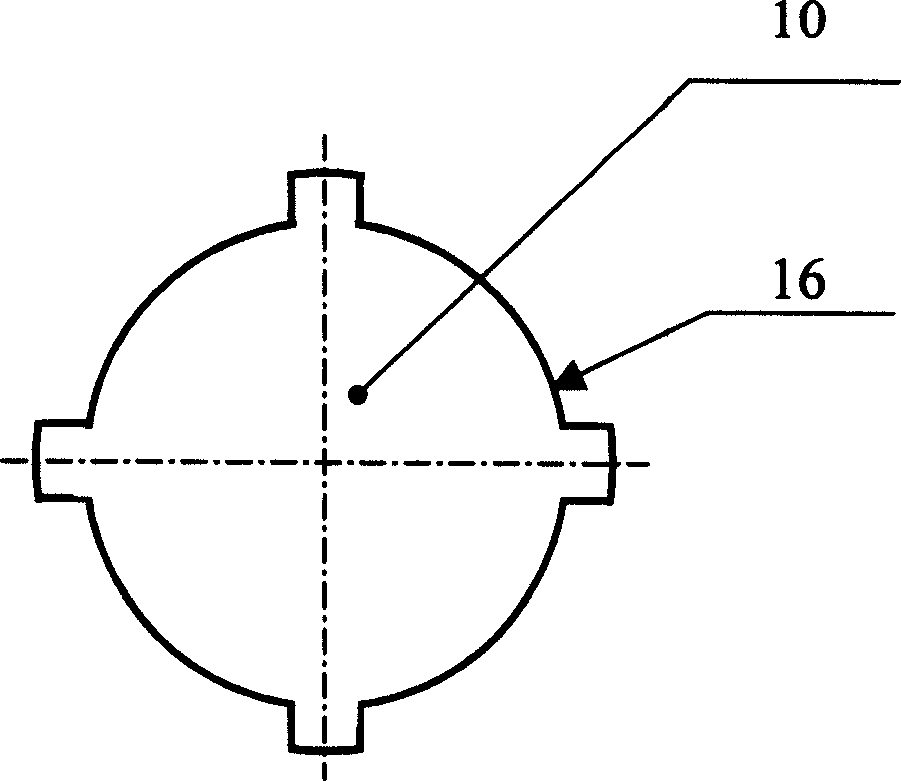

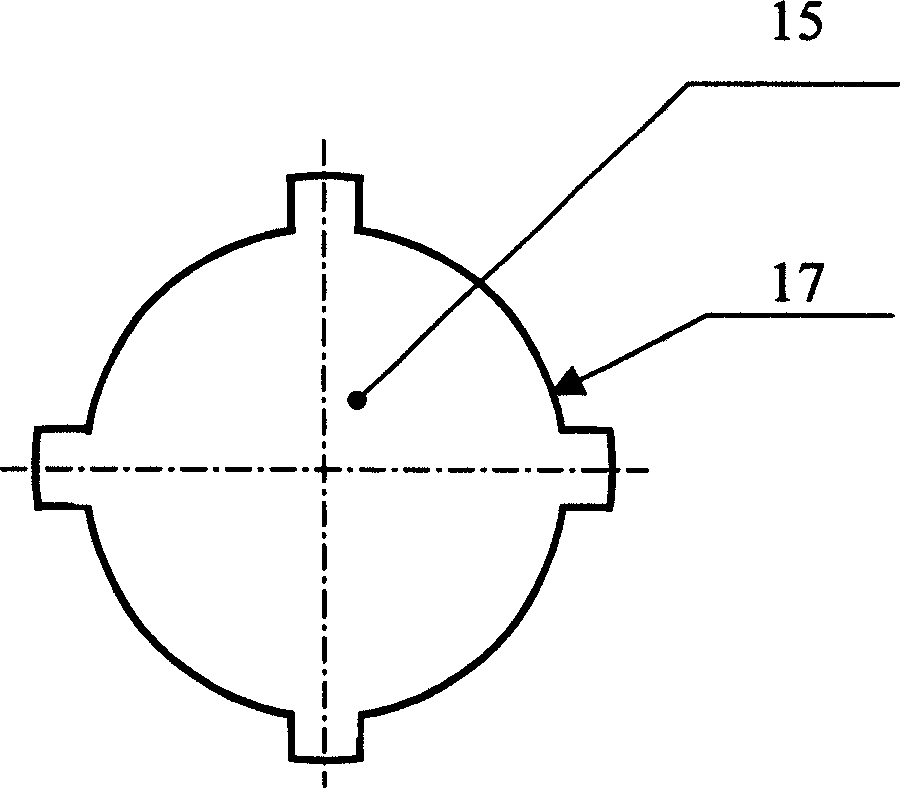

[0009] Below in conjunction with accompanying drawing, the present invention will be further described (with reference to figure 1 ). The principle is as mentioned above, the plunger 3 and the plunger sleeve 4 belong to a dynamic sealing fit, and the coil 5 drives the plunger 3 to move in the plunger sleeve 4 . There is an oil inlet hole 12 and a cylindrical spring chamber 18 inside the plunger 3 , so that the oil inlet 6 communicates with the oil inlet valve 1 . Between the plunger 4 and the lower end cover 13, a plunger return spring 14 is arranged along the axis line of the plunger 3, and about 1 / 3 of the length of the plunger return spring 14 is installed in the spring chamber 18, and the top of the spring and the spring chamber top surface contact. The valve seat 11 of the oil inlet valve is designed on the top of the plunger, which is beneficial to further reduce the volume of the compression chamber 8 . The shape of the oil inlet valve spool 10 is as figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com