Composite building construction member of cold bending thin wall lattice configuration steel and concrete and its producing method

A technology of cold-forming thin-walled and building components, which is applied in the direction of building components, building structures, buildings, etc., to achieve the effects of avoiding support and formwork engineering, reducing the structure's self-weight, and avoiding steel bar processing engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

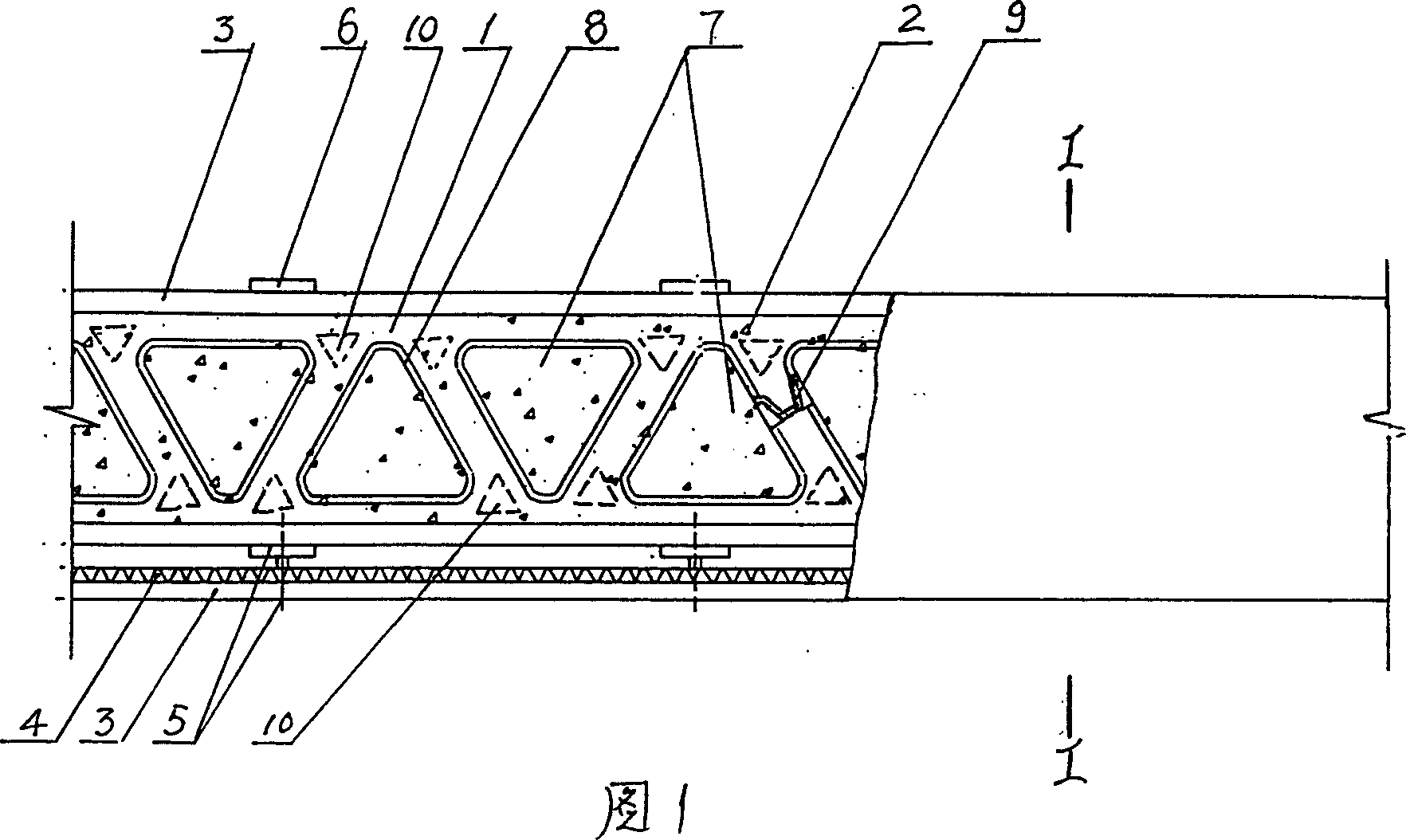

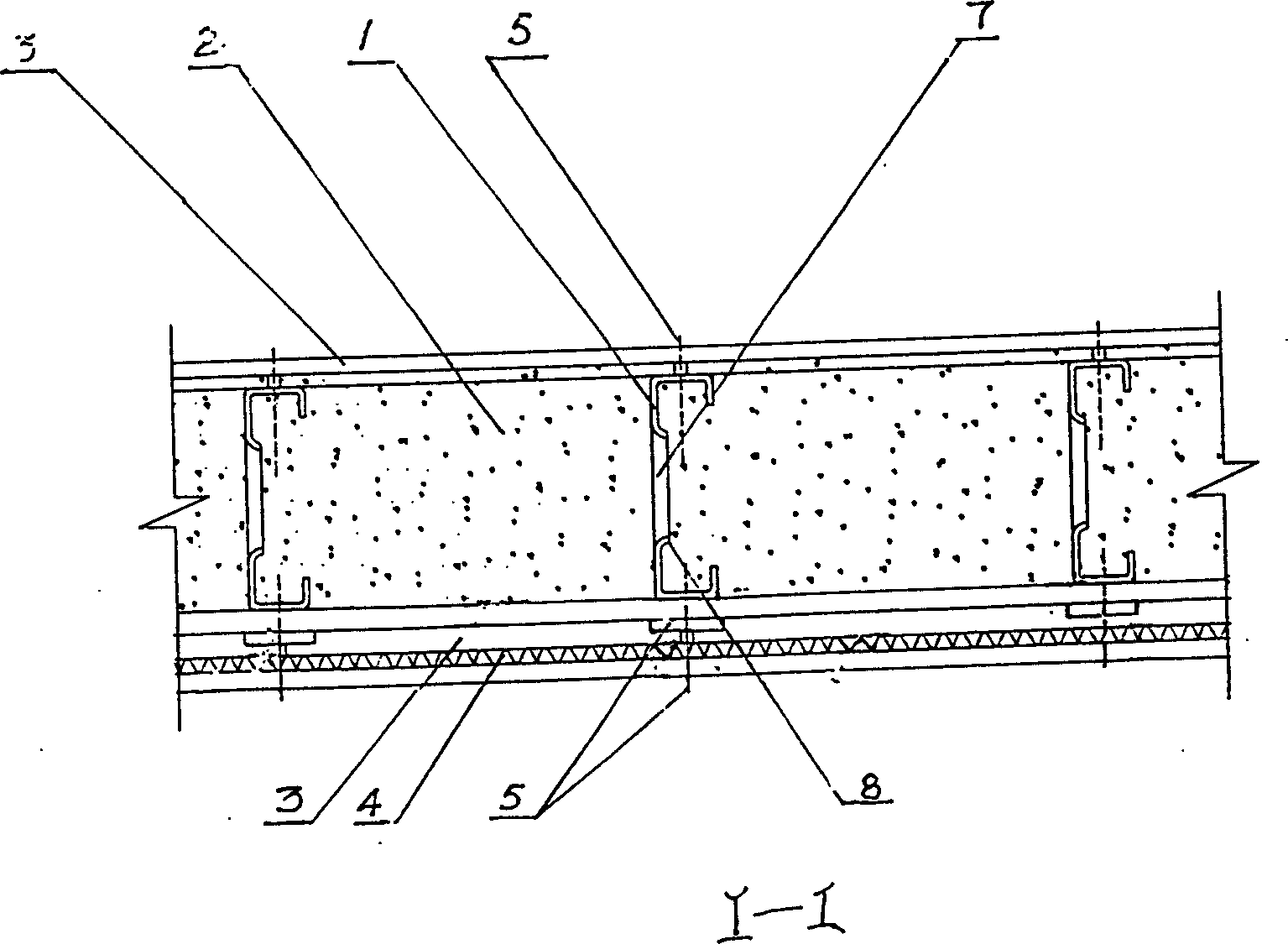

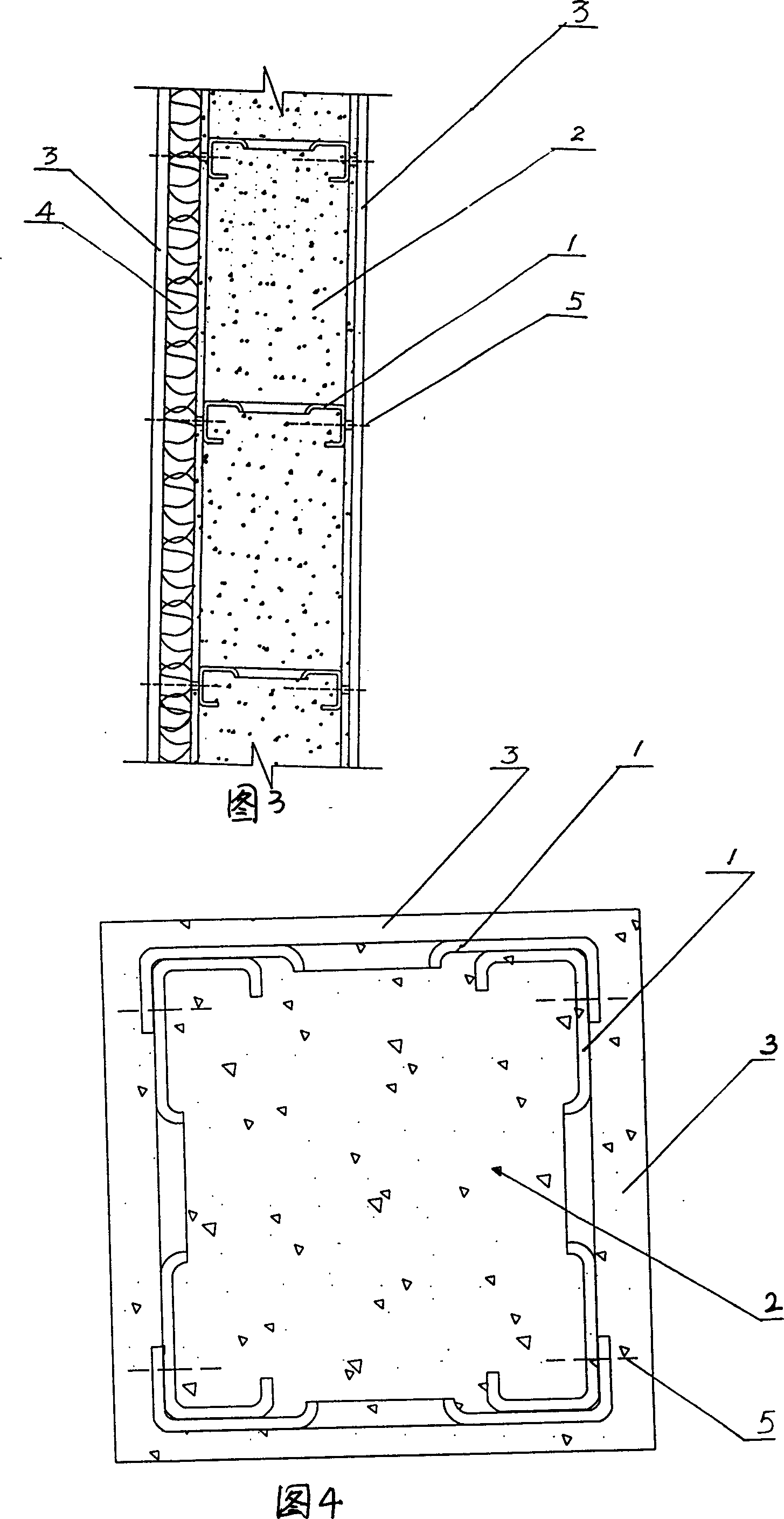

[0027] One of the embodiments shown in Figures 1 and 2 is a building floor member. According to the length × width of the floor, the cold-formed thin-walled lattice steel 1 with a C-shaped cross-section is arranged in parallel at intervals and combined with steel plates. The transition pieces 6 and self-tapping screws 5 are threaded to form a steel skeleton of cold-formed thin-walled lattice steel, and a template 3 connected to the steel skeleton, and the permanent template 3 has an insulating surface layer 4, which is poured into the template. Concrete2. The web surface of the cold-formed thin-walled grid steel with C-shaped cross-section is provided with positively and reversely arranged nearly triangular holes 7, and the periphery of each hole 7 has a curling edge 8 to form a reinforced flange. The two flanges form oblique U-shaped webs 9 between the holes, and nearly triangular pressure grooves 10 are arranged at the joints between the webs 9 and the flanges.

[0028] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com