Active aluminium oxide static bactericidal filter for waste water treatment and use

A technology of activated alumina and filtration device, applied in water/sewage treatment, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. Deal with the problems of high cost and construction cost, and achieve the effect of simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

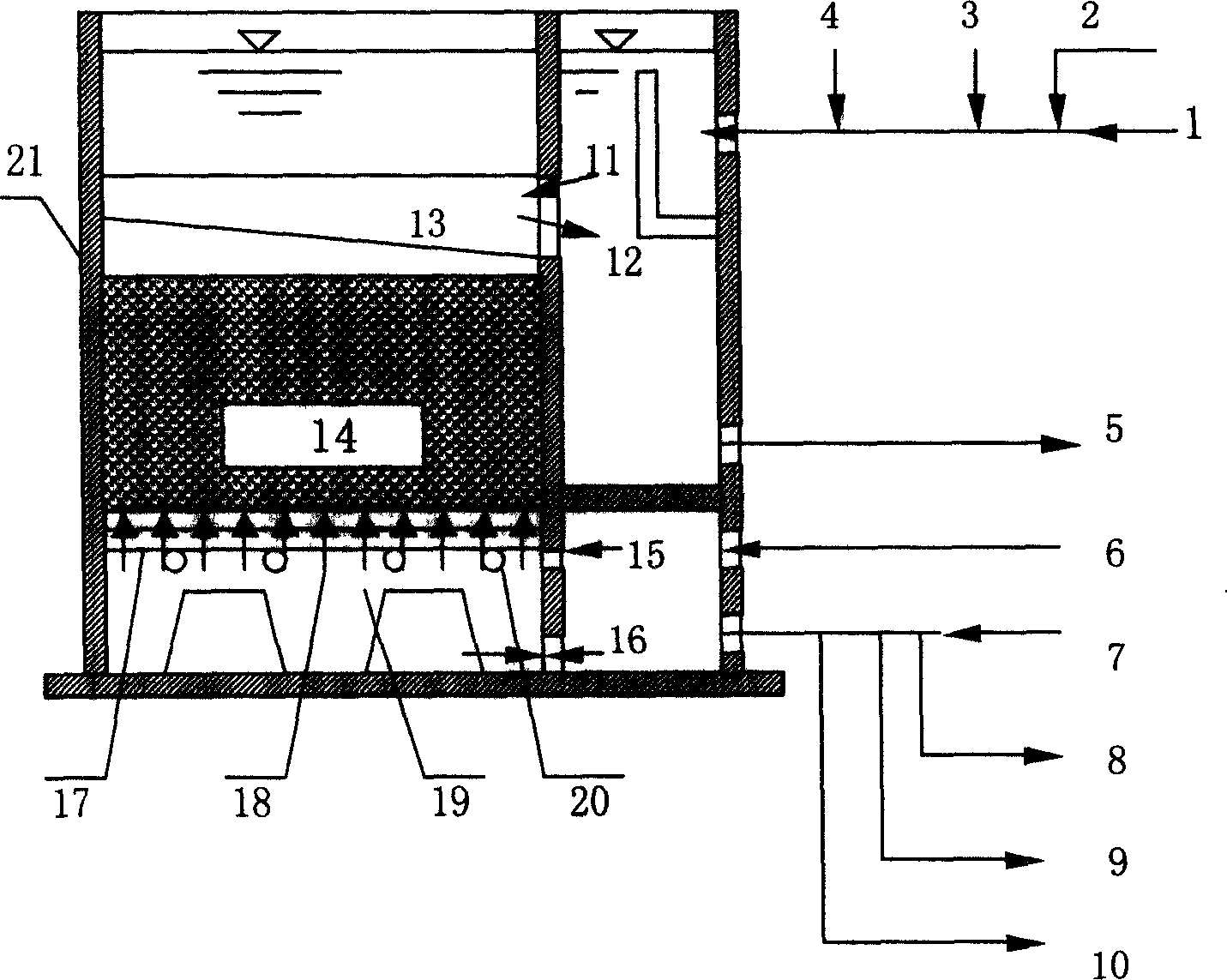

Method used

Image

Examples

Embodiment 1

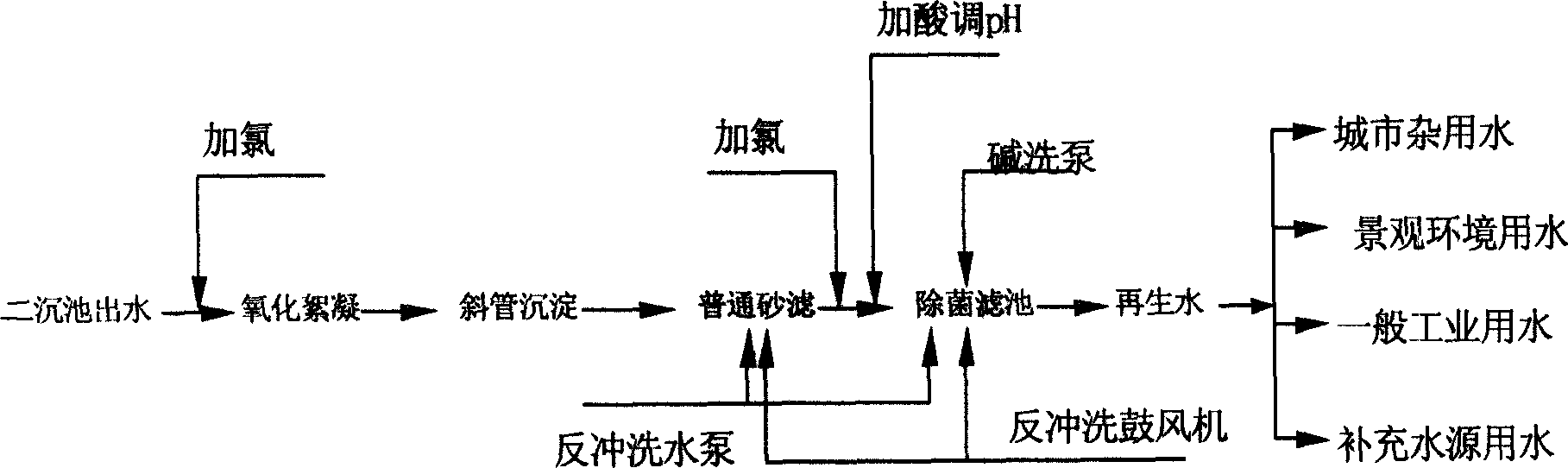

[0030] The first activated alumina electrostatic sterilization process for sewage recycling uses the effluent from the secondary sedimentation tank of the secondary sewage treatment plant as the water source, which is pretreated by adding chlorine, oxidizing flocculation, sand filtration, and then passing through the activated alumina electrostatic sterilization filter device. deal with. The water quality of the effluent fully meets the water quality standard for urban miscellaneous water for urban sewage recycling (GB / T 18920-2002) and the water quality standard for landscape environment water (GB / T 18921-2002).

Embodiment 2

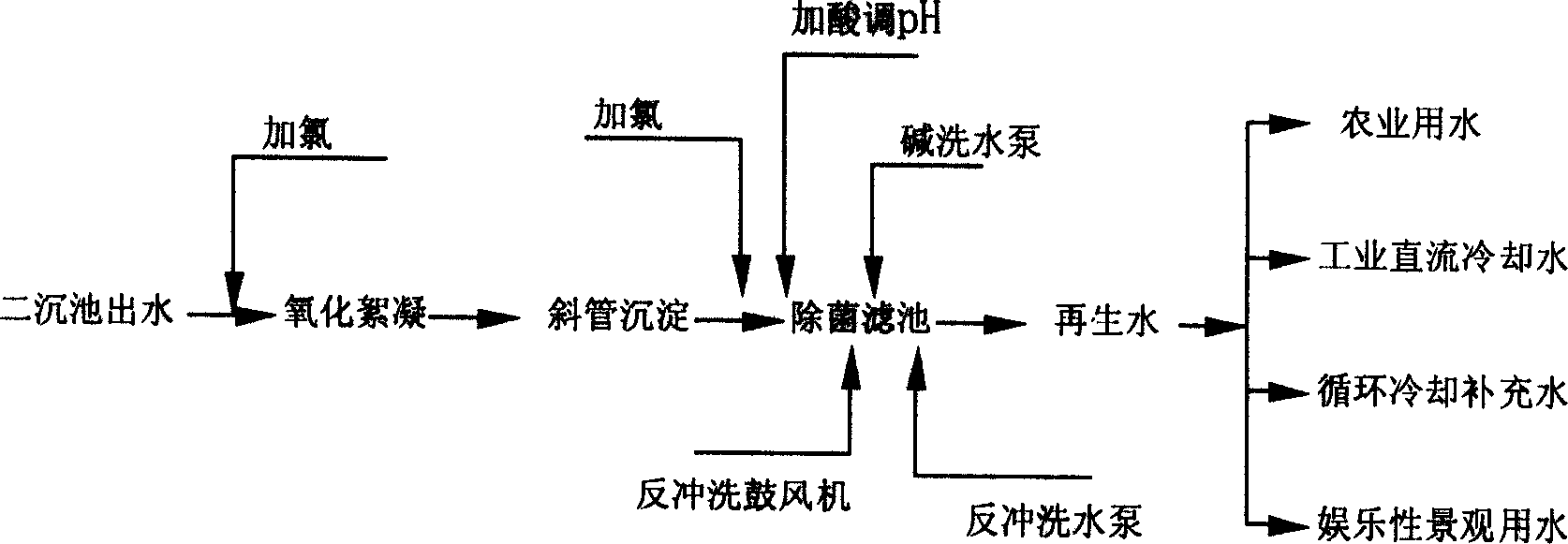

[0032] The second sewage regeneration process utilizes activated alumina electrostatic sterilization process, which uses the effluent from the secondary sedimentation tank of the secondary sewage treatment plant as the water source, pretreatment by adding chlorine, oxidizing flocculation and sedimentation, and then treating it with an activated alumina electrostatic sterilization filter device. The quality of the effluent water conforms to the water quality standard (GB 50335-2002) for reclaimed water used in industrial circulating cooling systems as supplementary water and the water quality requirements for other industrial production water.

Embodiment 3

[0034] The third kind of sewage recycling process utilizes activated alumina electrostatic sterilization process, which uses the effluent of the secondary sedimentation tank of the secondary sewage treatment plant as the water source, adds chlorine, oxidizes, flocculates and precipitates, pre-treats with ordinary sand filtration, and then passes through the activated alumina electrostatic sterilization filter device Treatment, followed by RO desalination and mixed bed treatment. The effluent water quality can meet the requirements of desalted water for power plant boilers and water quality for electronic industries. In the above new process, the removal rate of the total number of bacteria and coliform bacteria in the effluent of the activated alumina electrostatic sterilization filter device can reach 99.99-99.9999%, and the SDI is less than or equal to 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com