Distributing method for ceramic tile

A ceramic tile and cloth technology, applied in the field of ceramic tile cloth, can solve the problems of insufficient color of seepage tiles, monotonous large-grained bricks, and monotonous color of pure-colored bricks, etc., and achieve the effect of fine and rich colors and natural and smooth texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

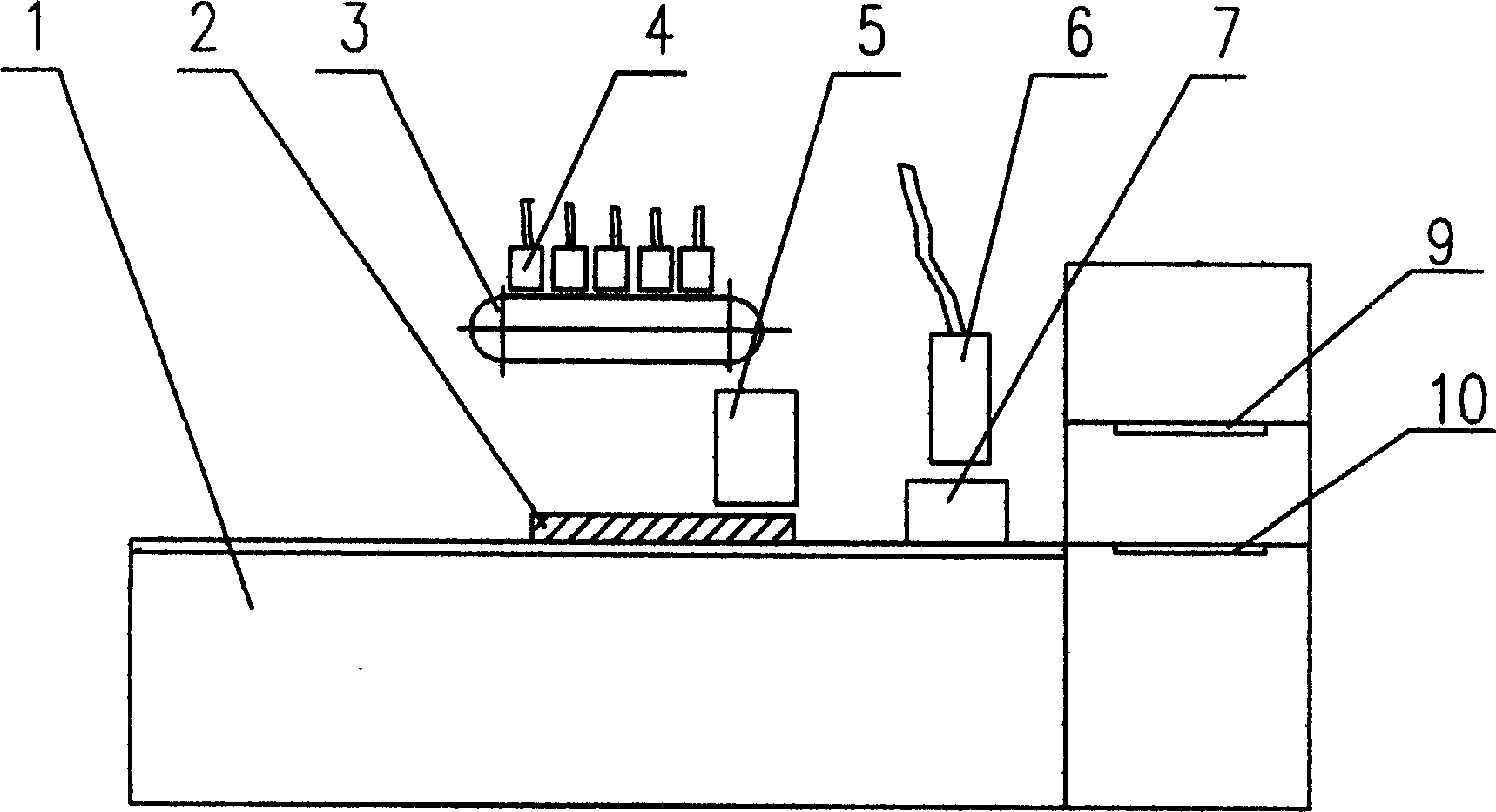

Method used

Image

Examples

Embodiment 1

[0012] By chemical composition (weight percent): SiO 2 73.5%, Al 2 o 3 17.8%, CaO 1.0%, MgO 0.72%, Na 2 O 4.4%, K 2 O 2.55%, the weight percent content of various raw materials is calculated as follows: Guangxi sand 20%, Guangxi 1# sand 15%, lithium china stone 12%, sodium stone 22%, potassium stone 12%, Takahashi white clay 12%, ball Soil 7%, weighed and pulverized to less than 10mm according to the proportion, and ball milled into 250 mesh sieve with a residue of ≤0.8% mud. Add a certain amount and percentage of special coloring materials for the ceramic green body as required, stir evenly, and then spray and granulate to form powders of various colors with a water content of 6-7% for use. The powder ratio of various colors is as follows:

[0013] (1) Deep black material: plain white material + 5% black color material

[0014] (2) Black coloring material: plain white material + 3% black coloring material

[0015] (3) Gray material: plain white material + 0.1% black ...

Embodiment 2

[0021] Carry out according to each step of embodiment 1, only use three sub-hoppers, change the color of powder into:

[0022] (1) Beige material: plain white material + 0.1% orange material + 0.2% titanium dioxide

[0023] (2) Super white material: ordinary white material + 5% zirconium silicate

[0024] Make micropowder and base material respectively according to the following ratio:

[0025] Micropowder Type Toner Weight Percentage Micropowder Weight Ratio Gate Height

[0026] Micro Powder A 100% Beige Color 20% 20cm

[0027] Micro powder B 30% beige color + 70% super white 40% 40cm

[0028] Micropowder C 100% super white material 40% 40cm

[0029] Base material 40% beige color + 60% super white

[0030] Its characteristics are: because the present invention adopts the layer-by-layer belt fabric method, the proportion of micropowder in each layer on the large belt is very uniform, so the patterns and patterns after mixing are consistent. The traditional front molding ...

Embodiment 3

[0032] Carry out according to each step of embodiment 1, only the quantity of sub-hopper is increased to 6. On the basis of five kinds of color micropowder, add a transparent particle of 1-20 mesh (the formula of transparent particle is: 30% wollastonite + 25% quartz + 25% feldspar + 10% high neighbor soil + 5% binding Clay + 5% burnt talc), the specific powder color and pigment ratio are as follows:

[0033] (1) Super white material: ordinary white material + 5% zirconium silicate

[0034] (2) Secondary white material: ordinary white material + 3% zirconium silicate

[0035] (3) Yellow material: plain white material + 5% zirconium silicate + 0.5% orange material

[0036] (4) Praseodymium yellow material: plain white material + 5% zirconium silicate + 0.3% praseodymium yellow material

[0037] The ratio of micropowder and base material is as follows:

[0038] Type Toner Weight Percentage Micro Powder Weight Percentage Ram Height

[0039] Micro powder 100% super white materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com