Composite protective cover insulator lightning arrester and producing method thereof

A technology of insulator arrester and composite jacket, which is applied to insulators, overvoltage protection resistors, electrical components, etc., can solve the problems of difficulty in controlling gap discharge voltage, complexity, and inability to promote composite insulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

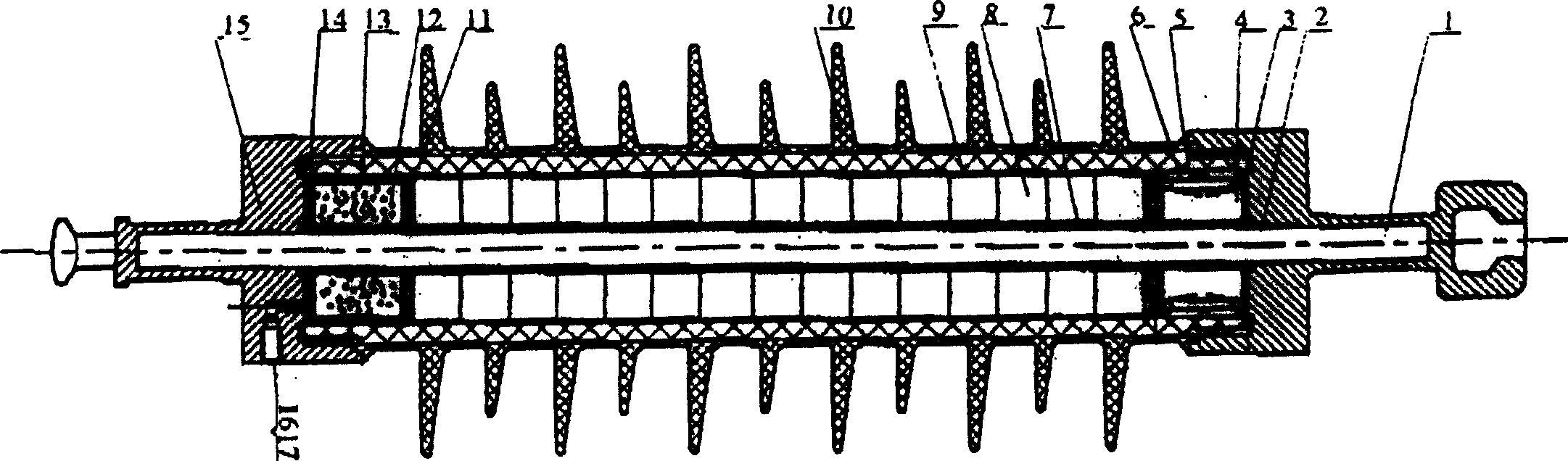

[0021] In order to better understand the present invention, two examples of 35 kV and 110 kV are introduced below to further illustrate the process of the present invention.

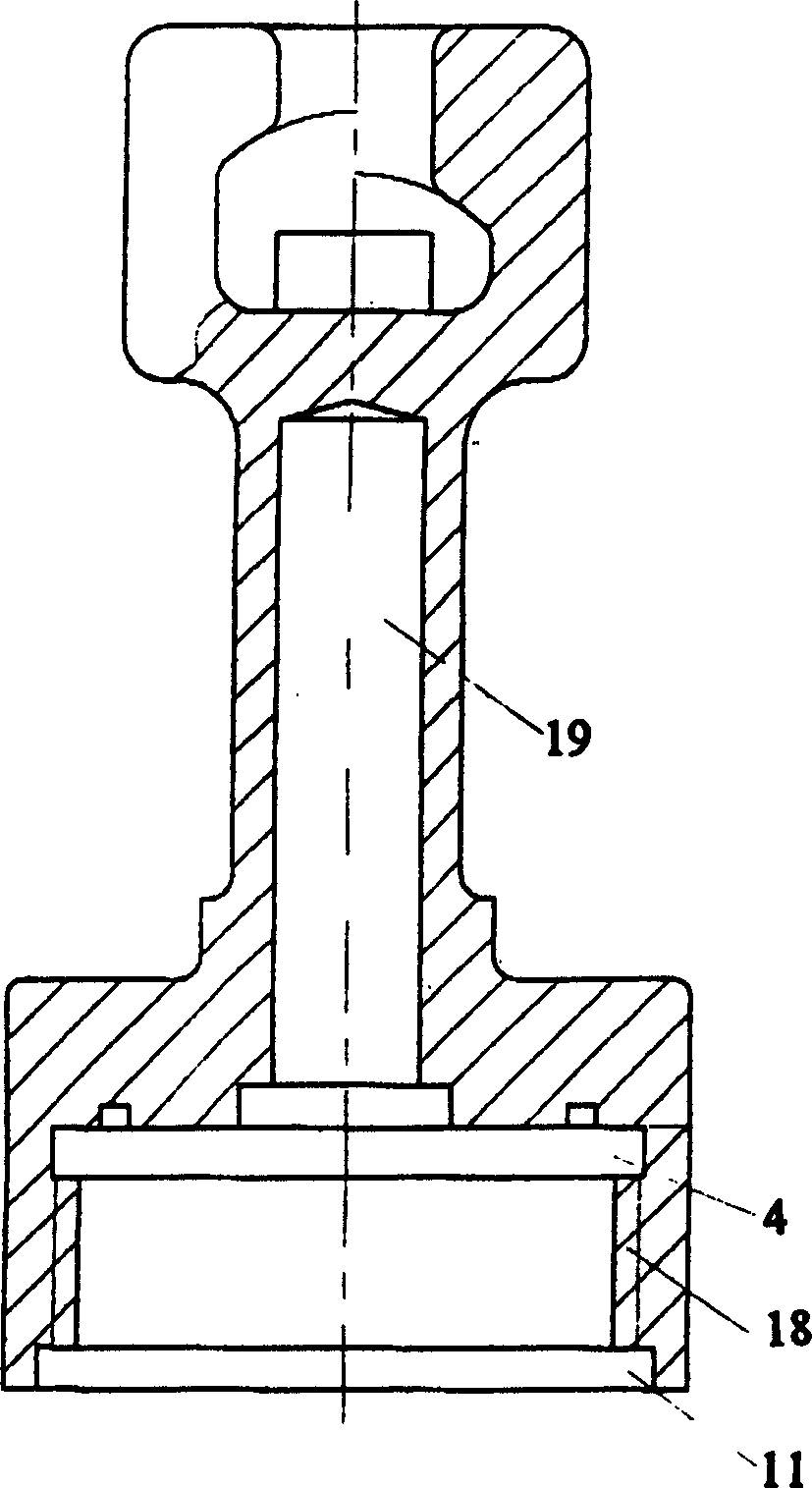

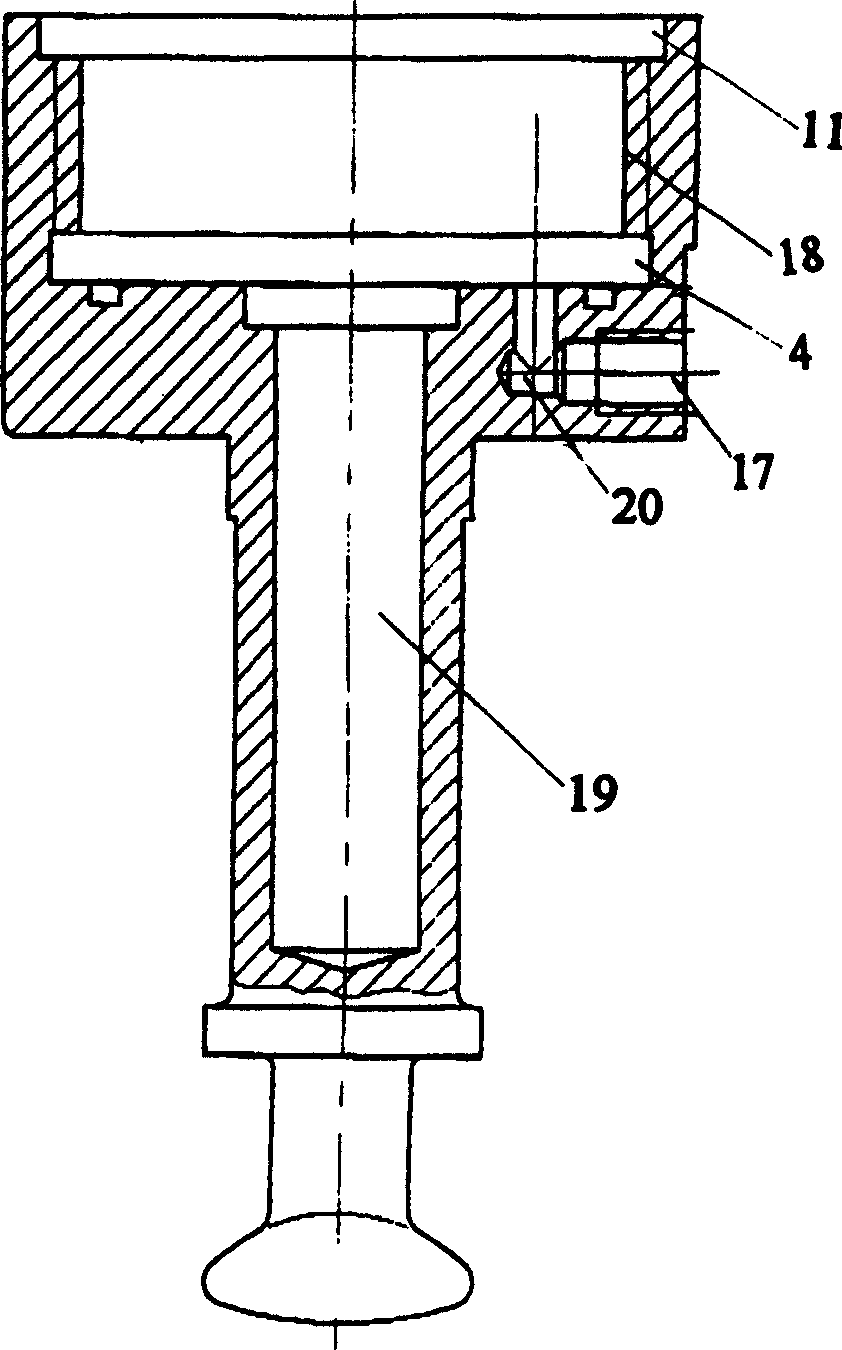

[0022] The first step: use glass fiber and epoxy resin to glue together and solidify to form an insulating mandrel 2 and an insulating sleeve 9, and coat a silicone protective layer 7 on the outside of the insulating mandrel and the sleeve.

[0023] In order to ensure the dryness inside the insulator arrester and avoid bringing in moisture, all the spare parts used, including zinc oxide ring, desiccant box, conductive tape, compression spring, upper and lower fittings, mandrel and sleeve, etc., are scrubbed with alcohol in advance After cleaning, put it in a 90°C oven for later use.

[0024] Step 2: Put the carefully selected mandrel in a special mold and inject glue to form a protective layer with a thickness of 5-10mm to buffer the impact on the mandrel in case the arrester explodes. The length of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com