Controlling method and apparatus for feeding motor transfer of optical record player

A technology of feed motor and control method, which is applied in magnetic recording, data recording, recording information storage, etc., can solve problems such as spinning, interference, and optical pickup cannot move, and achieve stable feed transfer, stable tracking track, Reduce the effect of joint properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The implementation of the method and device for controlling the transfer of the feed motor of the optical record player of the present invention will be described in detail below with reference to the embodiments of the accompanying drawings.

[0053] The structure and function of the present invention are described using an embodiment, and the structure and function of the present invention as described above are not limited to the embodiment shown here.

[0054] The present invention utilizes the rotation information of the disc, and after the feed motor moves to the track pitch every time one revolution is made, the existing feed and transfer servo drive unit and tracking servo drive unit are used to control residual errors that occur thereafter.

[0055] Here, the track pitch differs depending on the type of optical disc. DVD series is 0.74um, CD is 1.6um.

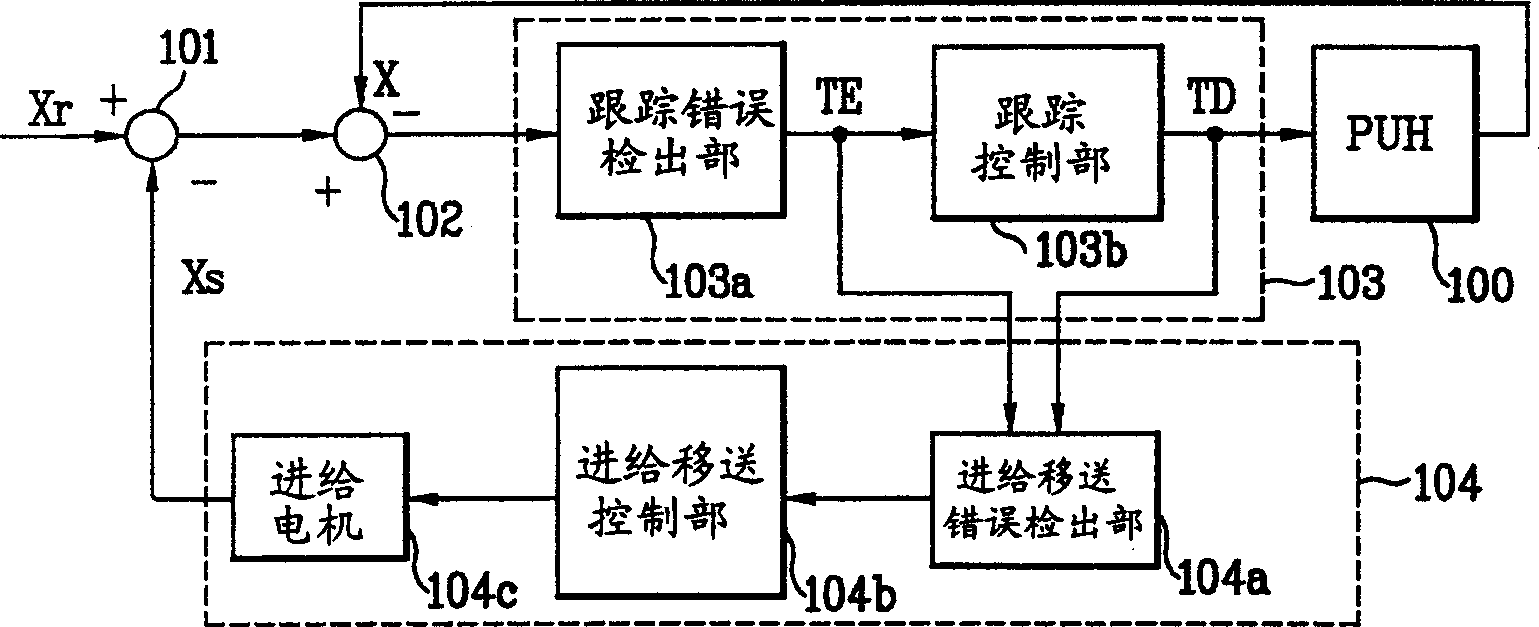

[0056] Figure 4 It is a structural diagram of an optical disk drive system according to the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com