Fastening method for high-strength concrete epibolic thin-layer and coupled columns

A high-strength concrete and concrete technology, which is applied in the direction of building reinforcement, building maintenance, structural elements, etc., can solve the problems of increasing the cross-sectional area of columns, occupying a large space, and unsightly appearance, so as to increase the cross-sectional area of columns and improve the bearing capacity , good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

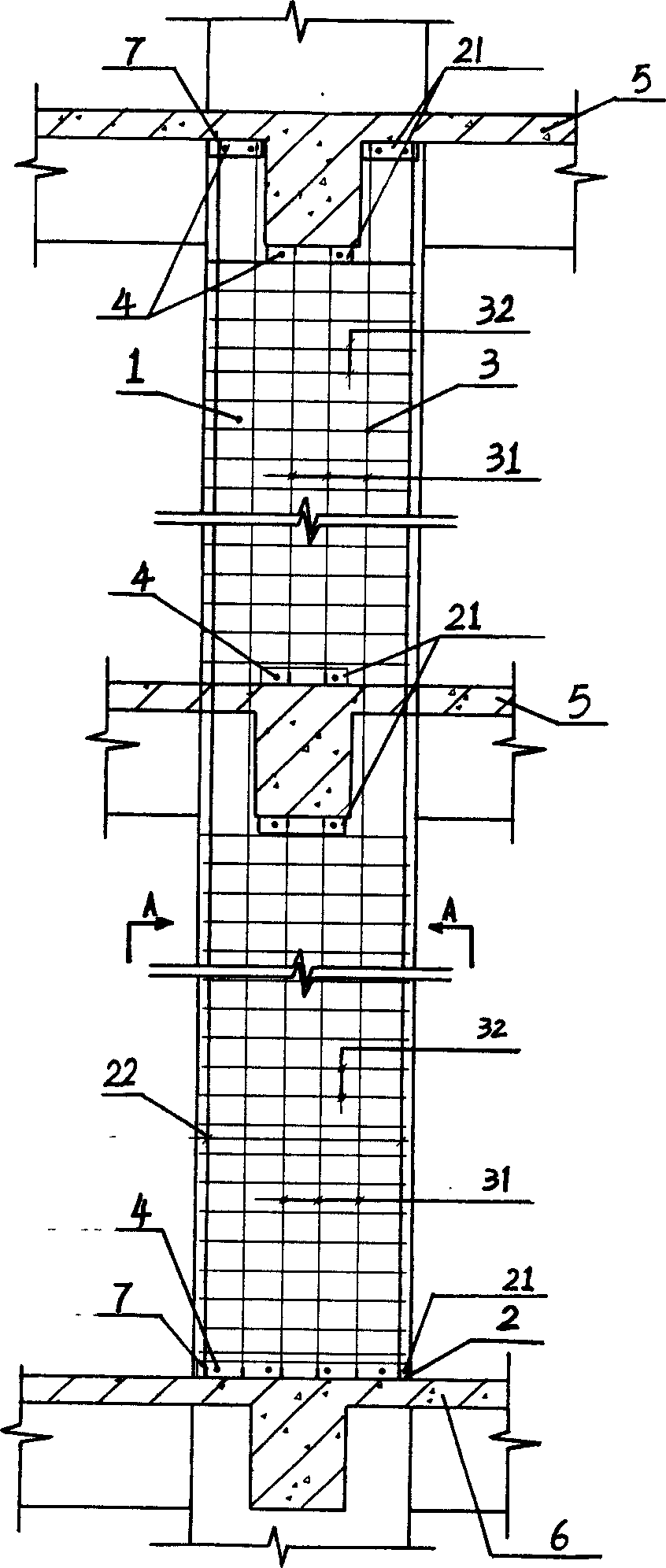

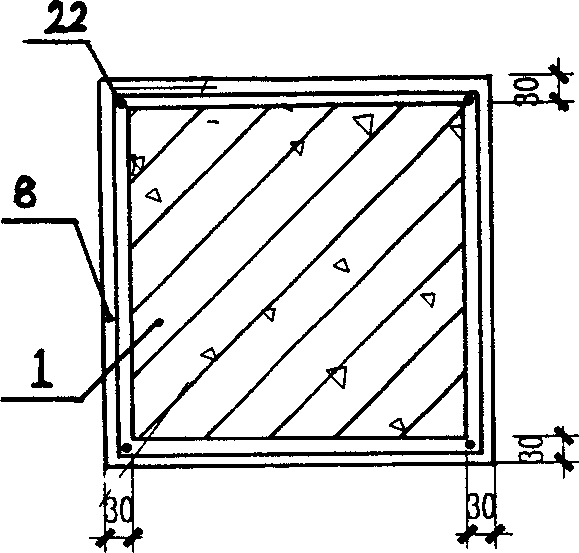

[0023] Such as figure 1 As shown, in this embodiment, a layer of high-strength concrete outer covering thin layer is added on the surface of the column. The outer covering thin layer is composed of concrete with a grade strength of C50 and high-strength steel wire mesh 3, and the high-strength steel wire mesh 3 is fixed on the reinforced The surface of the column 1 is covered with the concrete on the high-strength steel wire mesh 3 to form a high-strength concrete thin layer, and the thickness of the high-strength concrete thin layer is 30mm. In order to enhance the bonding force between concrete and steel wire mesh 3, a small amount of commonly used micro-expansion agent and polymer are added to the concrete. The high-strength steel wire mesh 3 is composed of φ4 cold-drawn steel wires, together with the concrete with a grade strength of C50, it forms a concrete high-strength steel wire mesh with a strength above C50, and the tensile strength of the steel mesh is above 450 MPa...

Embodiment 2

[0033] The characteristics of this embodiment are: the outer thin layer is composed of concrete with a grade strength of C40 and high-strength steel mesh, and the thickness of the high-strength concrete thin layer is 40mm. Concrete construction steps are identical with embodiment 1.

Embodiment 3

[0035] The characteristics of this embodiment are: the outer thin layer is composed of concrete with a grade strength of C60 and high-strength steel mesh, and the thickness of the high-strength concrete thin layer is 25mm. Concrete construction steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com