Reciprocating-rotating power converting mechanism without crank, and its engine and compressor

A technology of rotating power and conversion mechanism, applied in the field of compressors and piston engines, can solve the problems of mechanical power conversion efficiency limitation, gear tooth impact, affecting service life, etc., to improve energy conversion efficiency, improve emission performance, piston structure, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

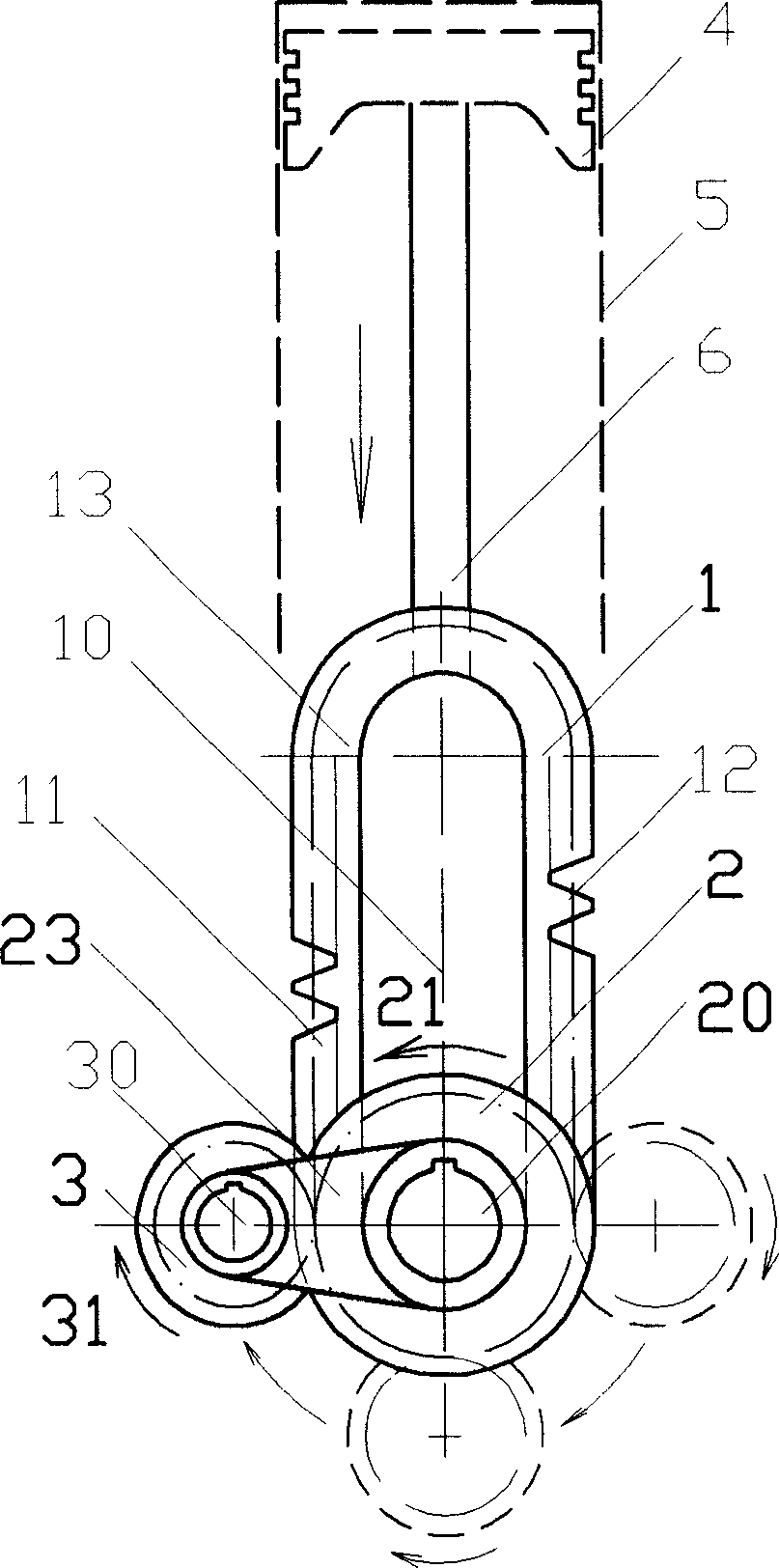

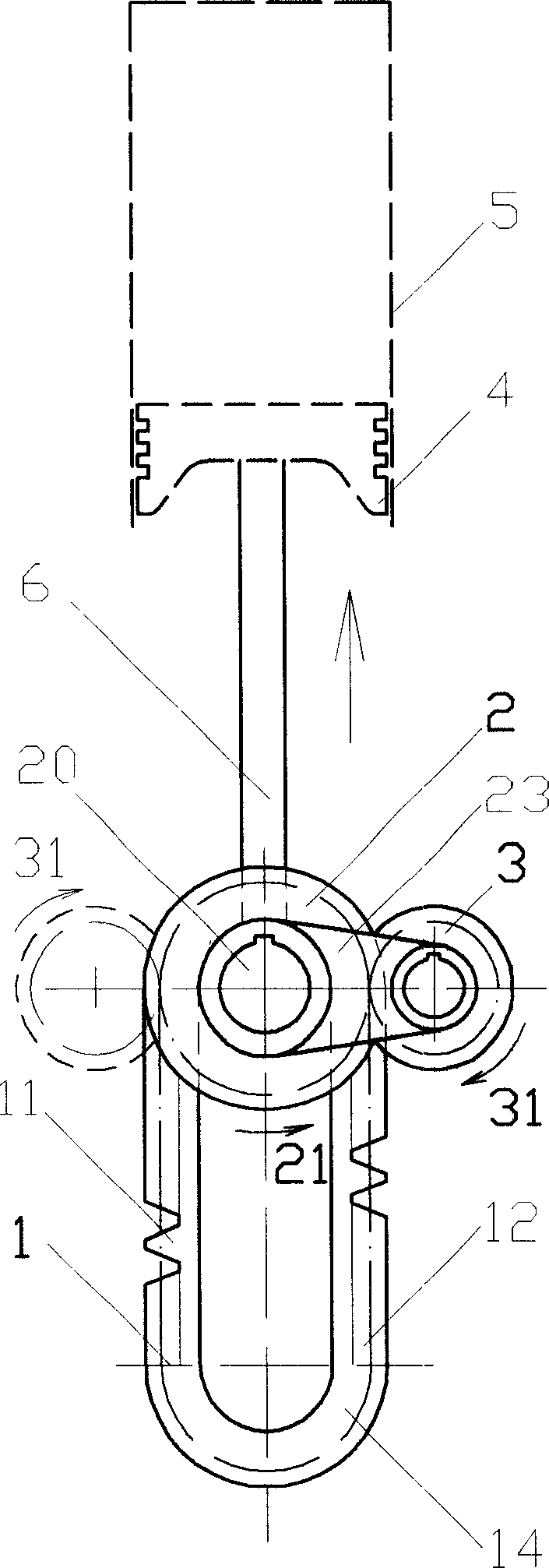

Method used

Image

Examples

Embodiment 8

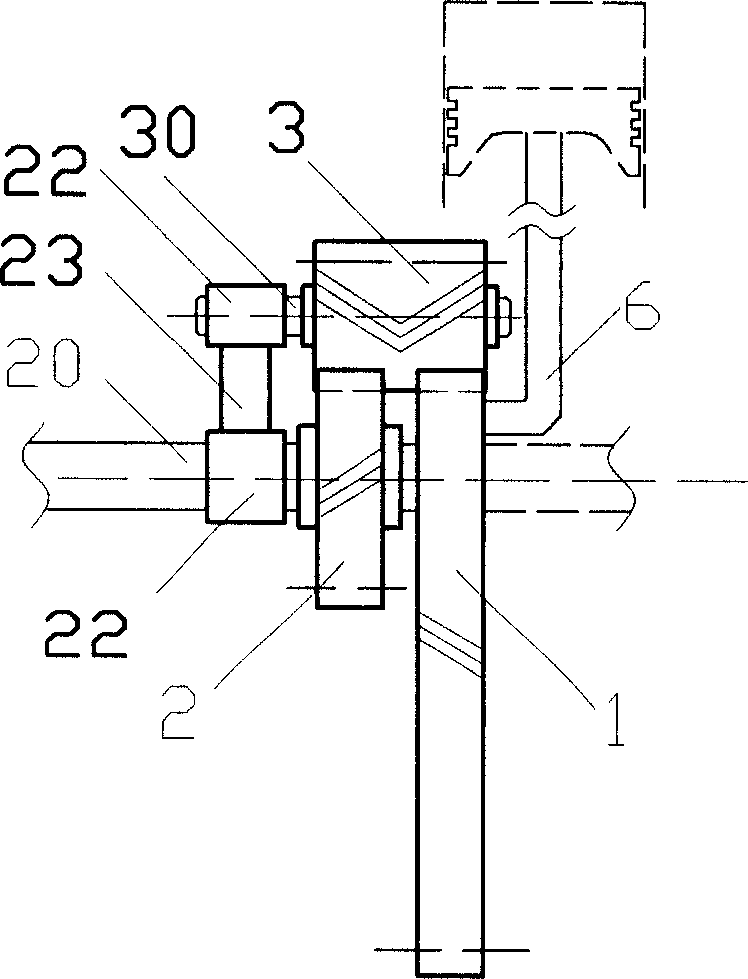

[0065] 2. In the above-mentioned embodiment, the planetary gear 3 can also be a gear train formed by coaxially connecting the front and rear gears 32, 33 (such as Figure 4 As shown), the front gear 32 is always directly meshed with the power gear 2, and the rear gear 33 is always directly meshed with the ring frame 1. The radii of the front and rear gears 32 and 33 can be the same or different: when the radii are the same, they can also be regarded as A long gear, similar to the previous example; when the radius is different, the radius of the power gear 2 and the radius of the semicircular gears 13, 14 at the two ends of the ring frame 1 can be different, so in the design, the relative size of their radii can be adjusted. Obtain different ratios of speed and torque output.

[0066] 3. In the above-mentioned embodiments, the power shaft 20 may not pass through the inside of the ring gear frame 1 (such as Figure 5 shown): At this time, the ring gear frame 1 can be a solid ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com