Transparent model alloy device

A model and alloy technology, which is applied in the field of devices for carrying out material science simulation experiments, can solve problems such as unclear photographic images, and achieve the effects of accurate measurement, high temperature control accuracy, and clear photographic images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

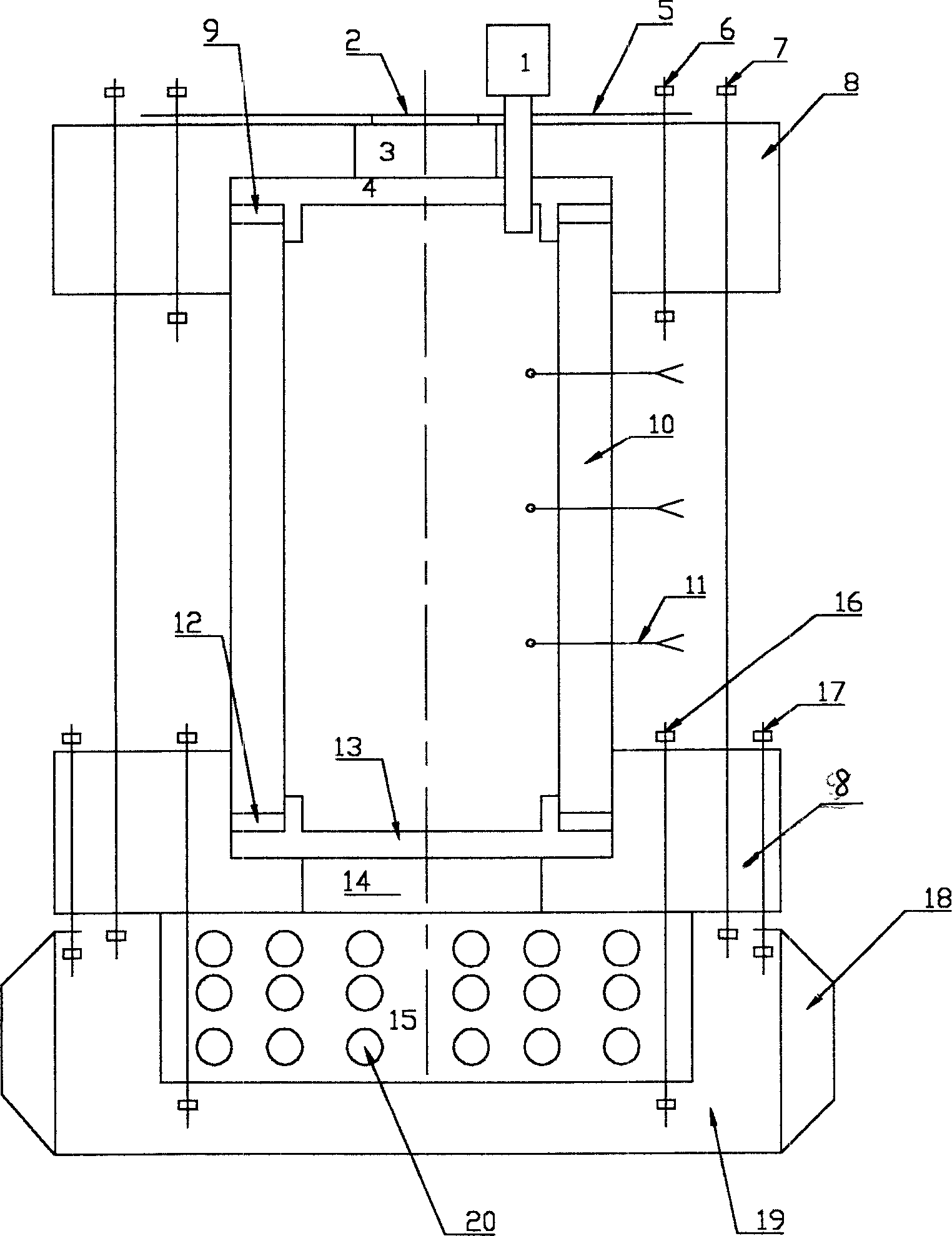

[0018] The transparent model alloy device comprises a quartz glass tube (10) containing the transparent model alloy succinonitrile, a temperature gradient platform and a detection system.

[0019] The temperature gradient platform is vertical, the upper heating platform is heated by a PTC heating module (3), and the lower cooling platform is cooled by a semiconductor refrigeration device (14); the temperature system adopts a Jackson-type temperature gradient platform to realize hot and cold platforms The distance between them can be adjusted arbitrarily, and the interval temperature has a linear relationship with the position change. The temperature of the hot stage and the cold stage is precisely controlled by using a super thermostat and a low-temperature thermostat, and the temperature in the quartz glass tube (10) is detected by a thermocouple (11). The temperature gradient hardly changes with the change of the moving speed of the sample. The PTC heating module (3) is pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com