Bearing assembly with brazing or soft soldering connecting part

A technology for bearing assemblies and connecting parts, which is applied in bearing assembly, bearing components, rolling contact bearings, etc., can solve the problems of high carbon steel welding cracks, welding slag splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

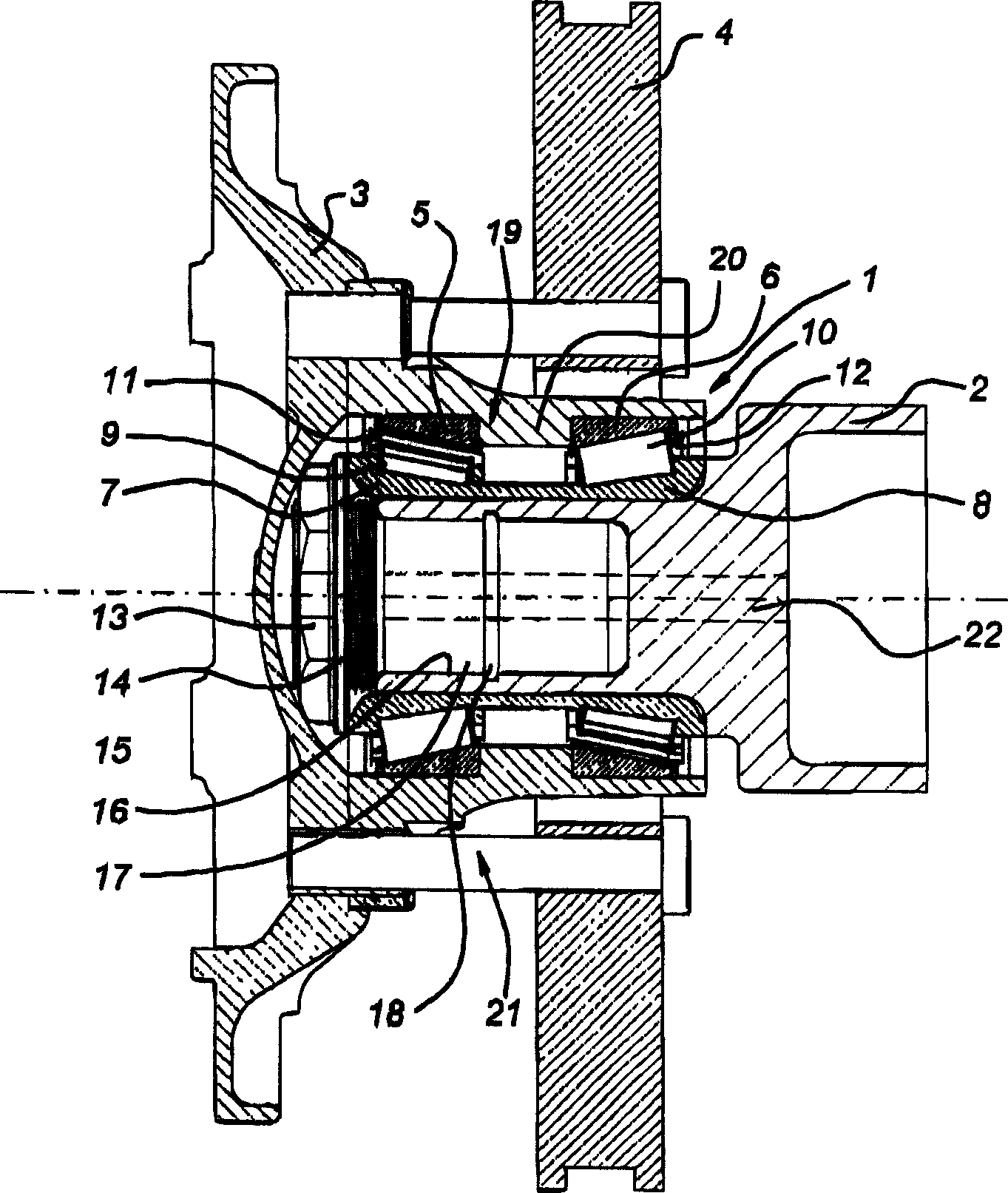

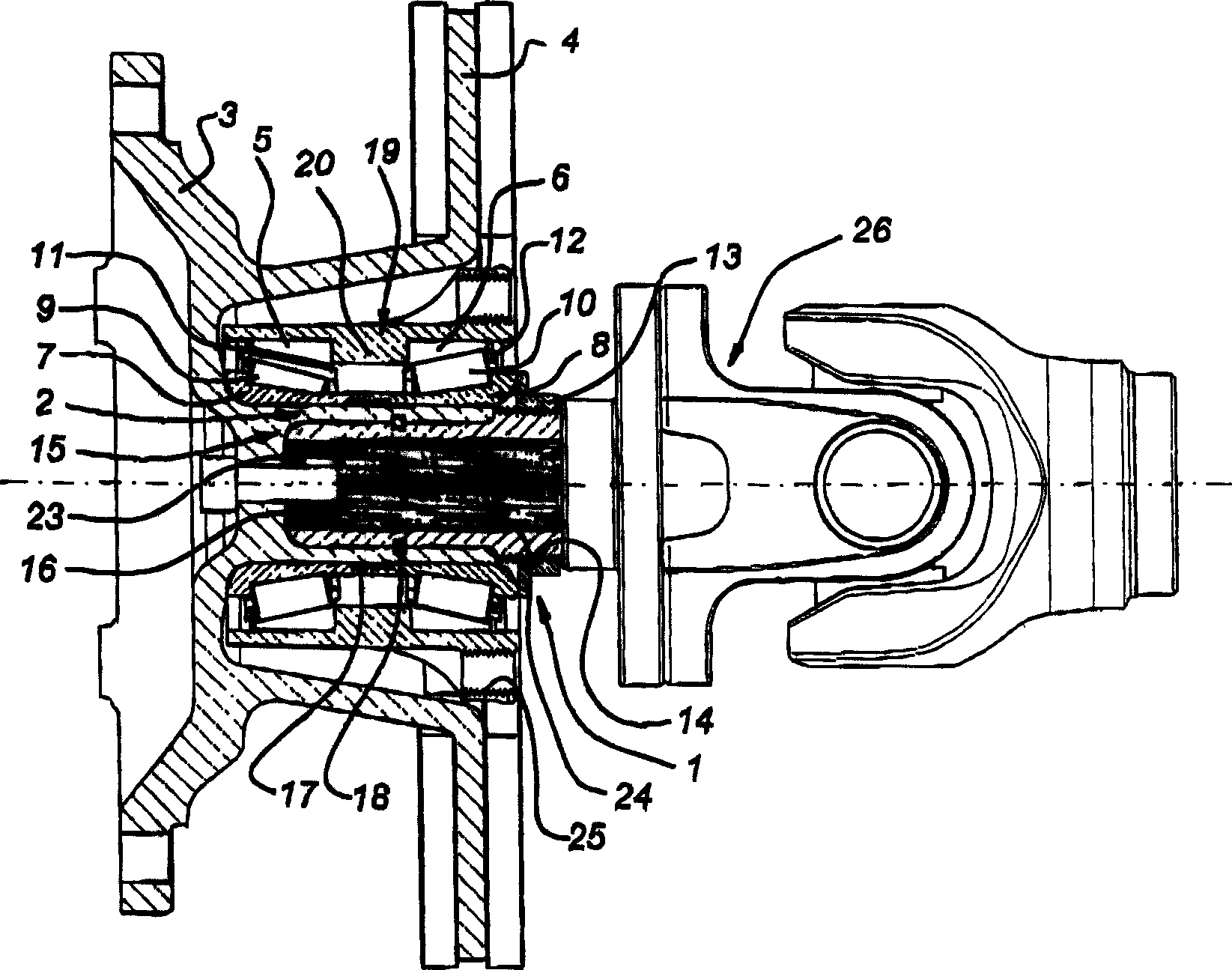

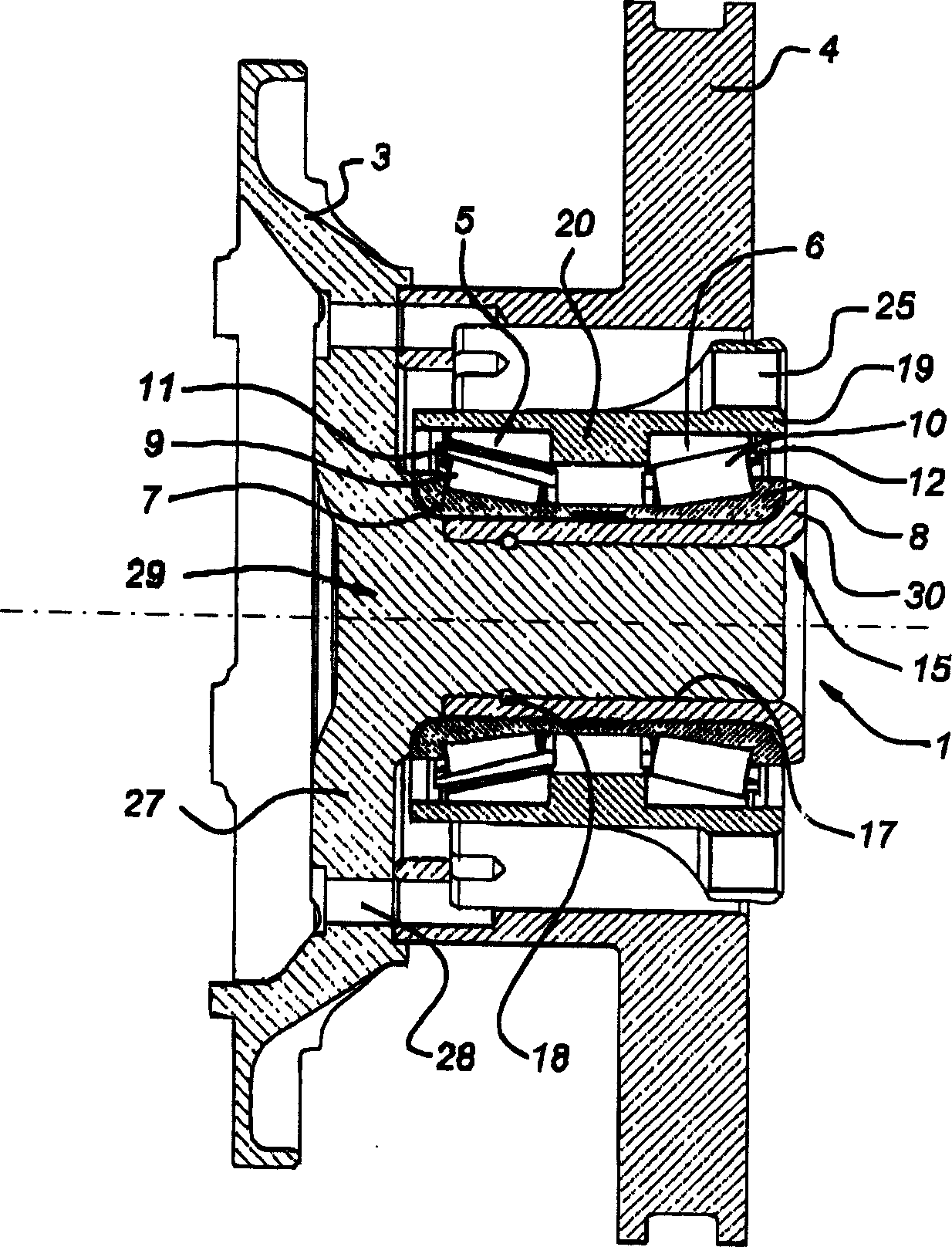

[0048] figure 1 The truck hub assembly shown in includes a bearing assembly 1 according to the invention attached to a steel hub element 2 fixed to the wheel suspension (not shown). A wheel rim 3 and a brake disc 4 are mounted on the bearing assembly 1 . The hub element 2 may comprise a tube end, which may have any cross-sectional shape, such as circular, square, triangular, conical, pyramidal, etc.

[0049] The bearing assembly 1 is of the double row tapered roller type with two outer retainers 5,6 and two inner retainers 7,8. A set of tapered rollers 9 and 10 are accommodated between the retaining rings 5, 7 and 6, 8, respectively, and these tapered rollers are held in a known manner by cages 11, 12, respectively.

[0050] In order to achieve proper performance of the bearing assembly 1, a certain axial preload should be applied to the tapered roller bearing. The preload is applied to the inner retainers 7 , 8 by means of nuts 13 which are screwed onto the threads 14 of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com