Disc and hub assembly for electromagnetic clutch in a compressor

An electromagnetic clutch and assembly technology, applied in the direction of magnetic drive clutches, non-mechanical drive clutches, clutches, etc., can solve the problems of damage to the friction surface of the disc 20 and the pulley, problems with the durability of the leaf spring 30, and reduced power transmission efficiency. , to improve power transmission efficiency, improve noise reduction effect, reduce noise and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the drawings.

[0035] In addition, description of the same configuration and function as conventional ones is omitted.

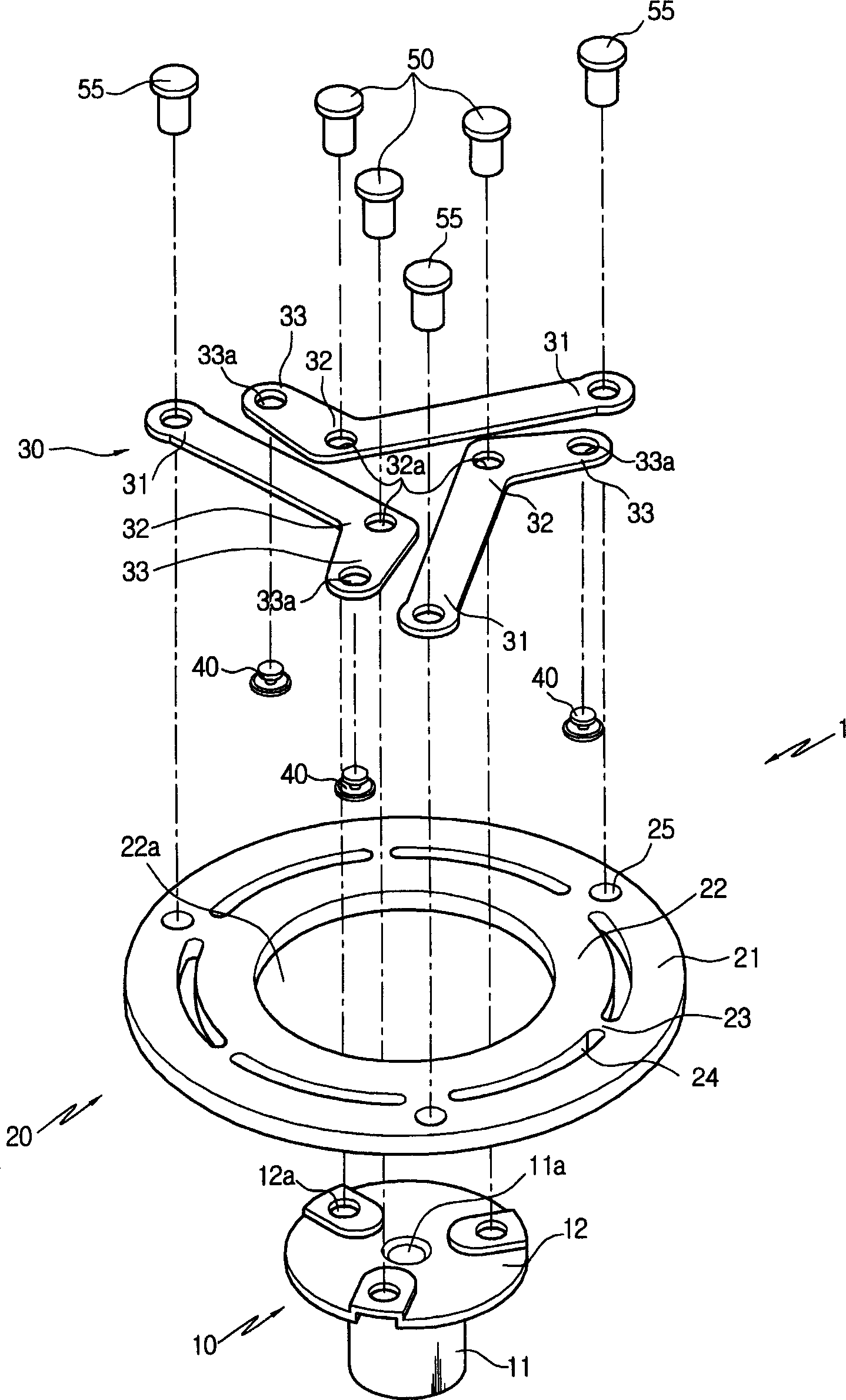

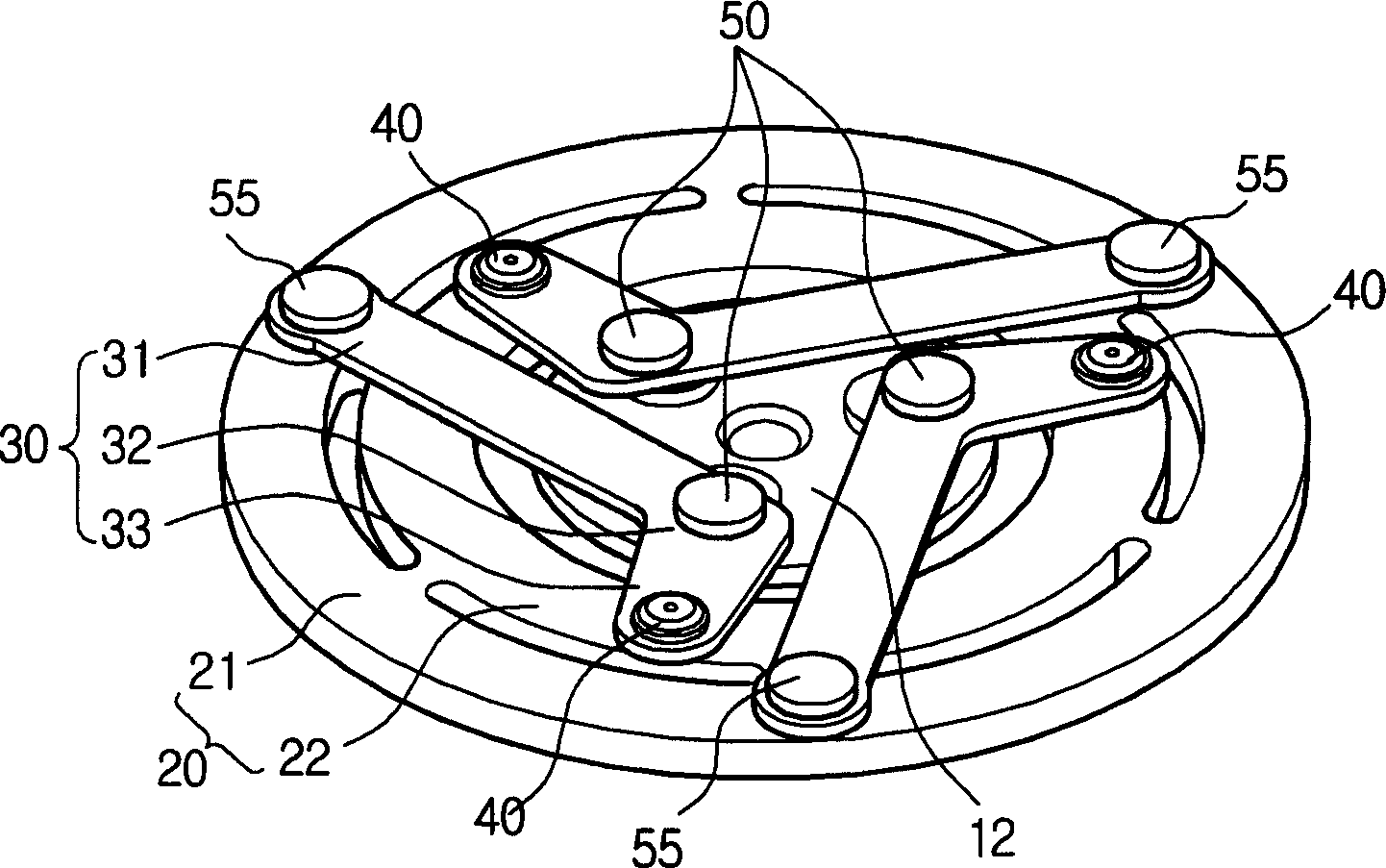

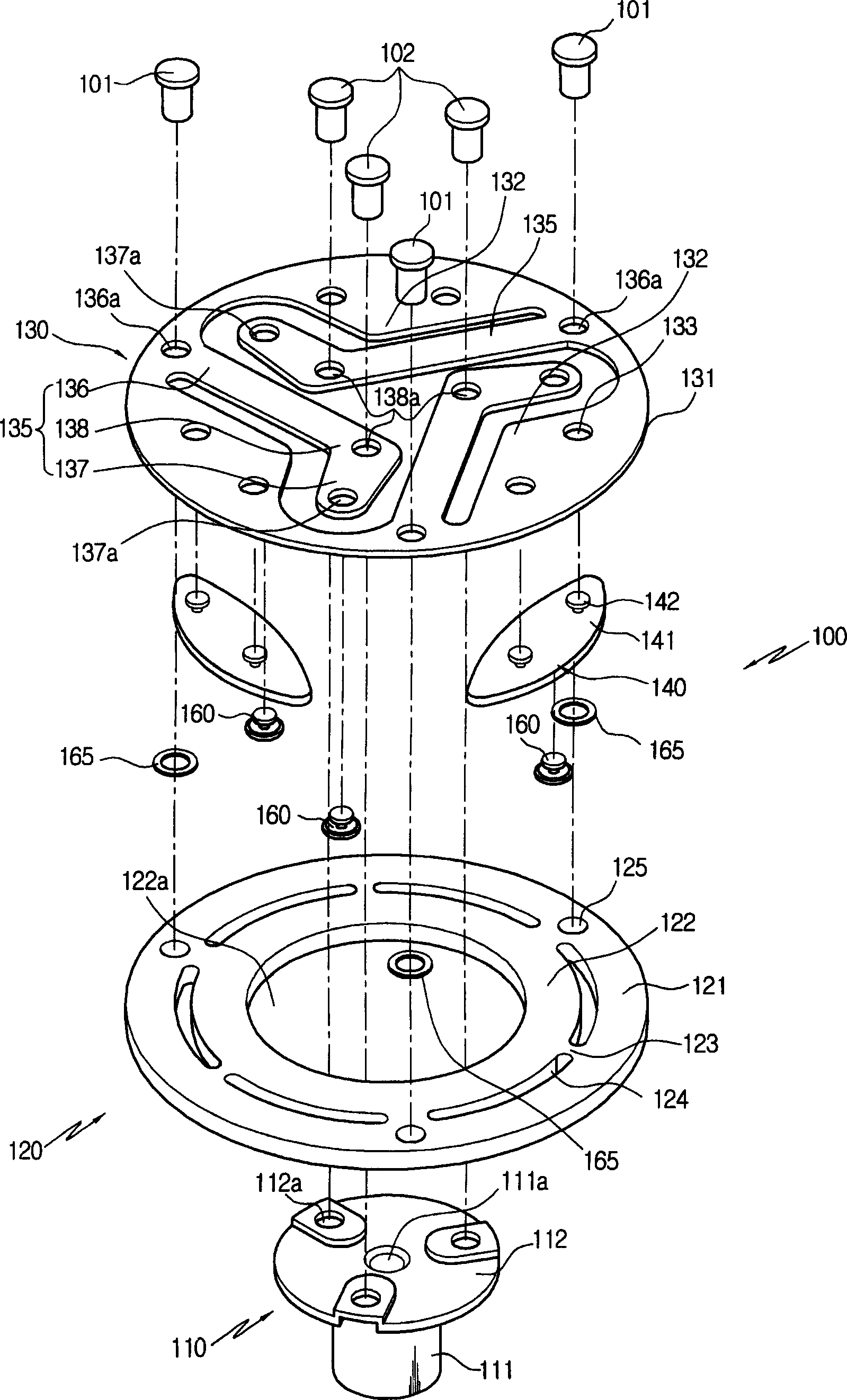

[0036] image 3 It is an exploded perspective view showing a disc and hub assembly of the first embodiment of the present invention, Figure 4 It is an assembly perspective view showing the disc and hub assembly of the first embodiment of the present invention.

[0037] As shown in the figure, the disc and hub assembly 100 of the present invention includes: a hub 110 , a disc 120 , a leaf spring 130 and a buffer unit 140 .

[0038] First, the hub 110 is composed of a hub main body 111 having an engagement hole 111a for spline engagement with a drive shaft (not shown) of a compressor (not shown), and a hub body 111 formed on the hub main body 111. The flange 112 on the side outer peripheral surface constitutes. A plurality of rivet engaging h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com