Passive non-contacting smart bearing suspension for turbo blood-pumps

A technology of blood pumps and bearings, applied in the direction of blood pumps, pumps, pump devices, etc., can solve the problems that simplicity and reliability are not the ultimate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

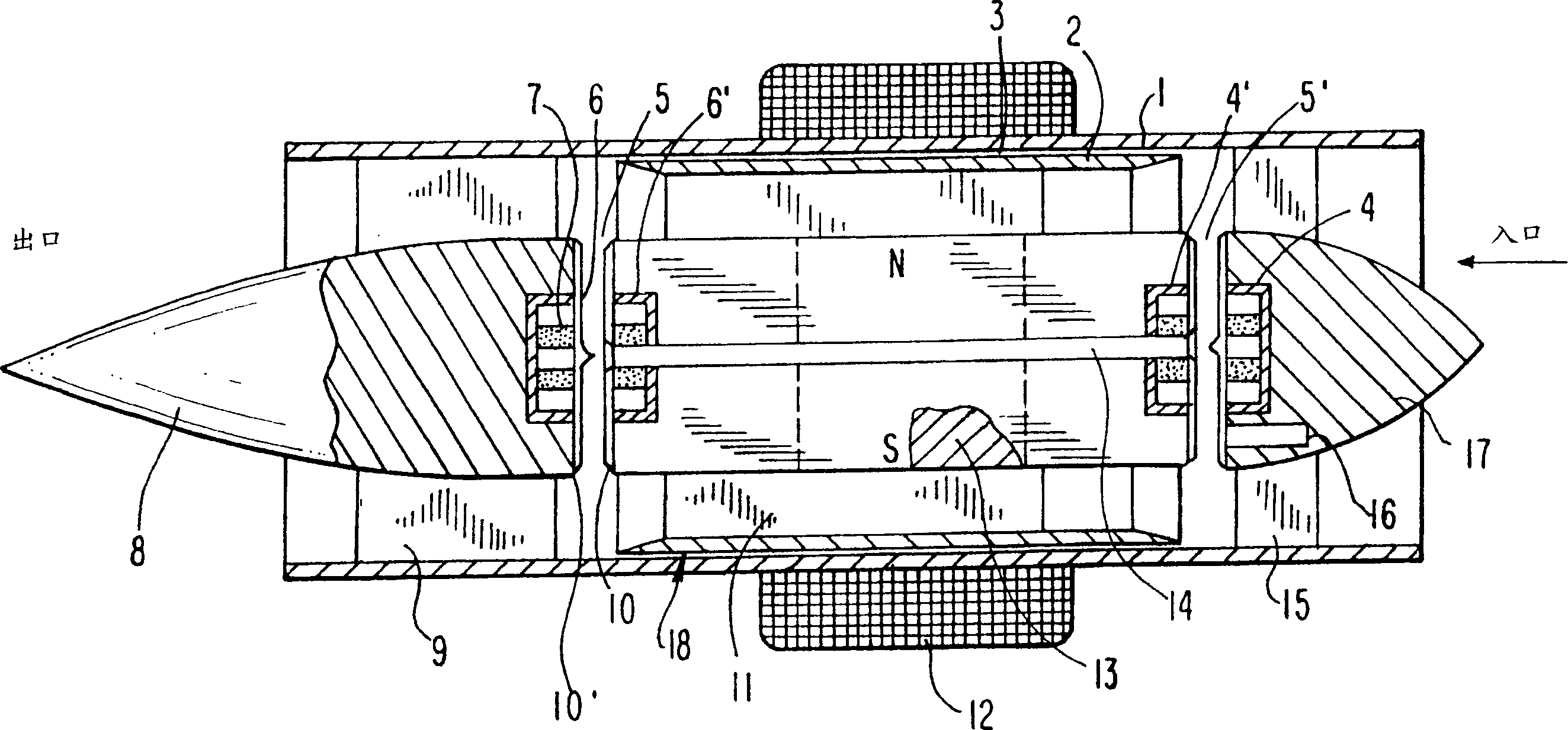

[0025]To better describe the main elements of the invention, figure 1 Only the main components of the axial flow booster pump are shown in the figure. An axial pump is shown in the figure, but this is not meant to be limiting. The same bearing suspension can also be applied to centrifugal booster pumps. This is illustrated in the Goldowsky patent cited above.

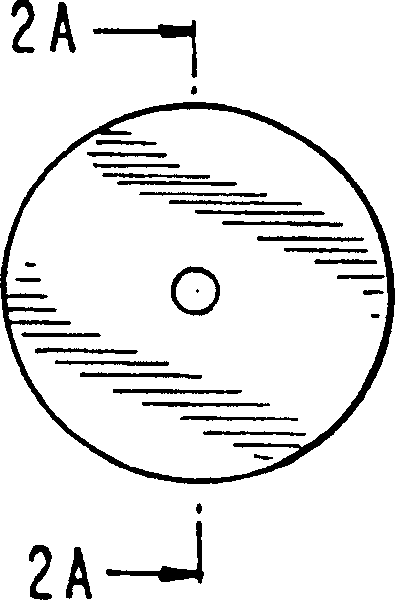

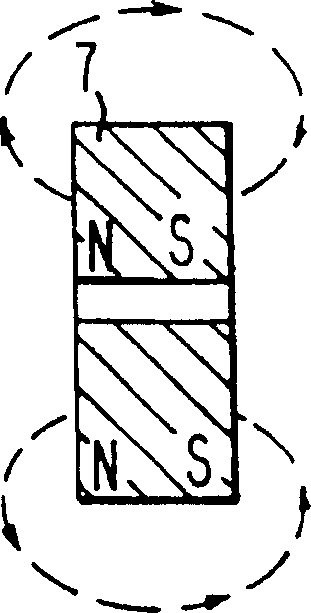

[0026] The rotor of the pump is generally depicted as item 18 . It includes helical impeller blades 11, circular bearing parts 2, magnet thrust bearings at each end, parts 4 and 4', thin windows 10 and 10', brushless motor armature magnet parts 13, and blood flow guide Hole 14, the pilot hole 14 is used to flush the rotor gap at each end. The concept of using a central shaft hole in the rotor to achieve interstitial flushing flow is covered by Goldowsky, US Patent No. 6,716,157, entitled "Improved Magnetic Levitation Blood Pump," issued April 6, 2004. The magnet assembly is hermetically sealed by a thin (typically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com