Concrete sleepers and their making process

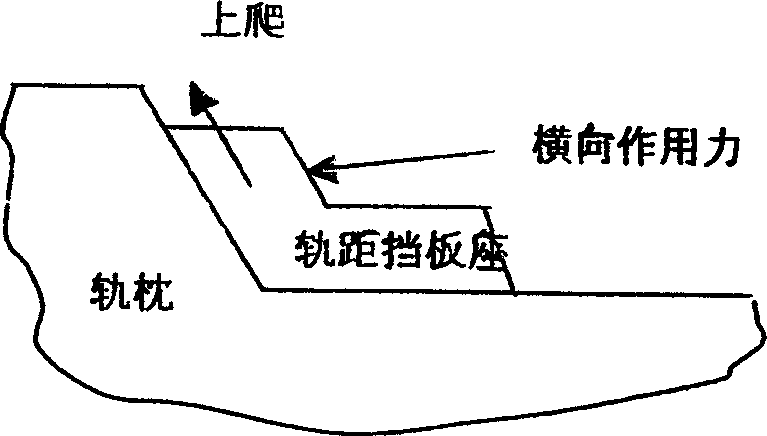

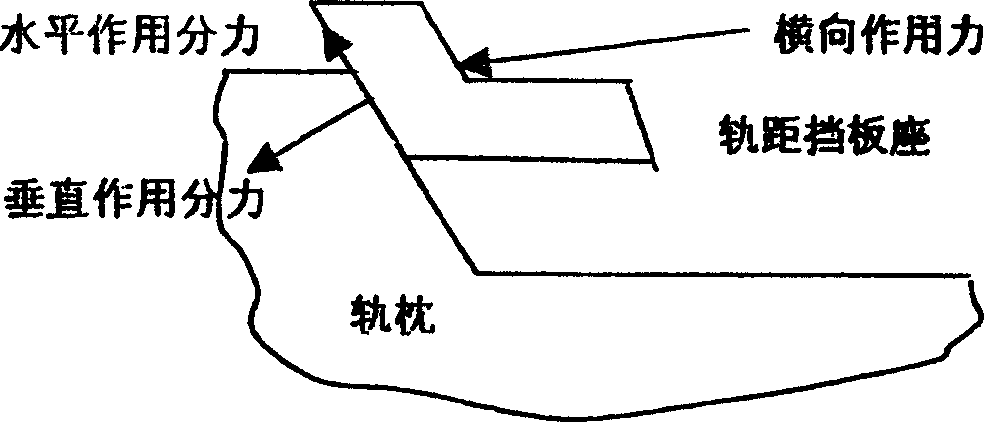

A production method and concrete technology, which are applied in the directions of rails, fixed rails, molds, etc., can solve the problems of easy loosening of the gauge baffle seat, inability to provide buckle pressure, and reduced contact area. Easy to break, the effect of changing the direction of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

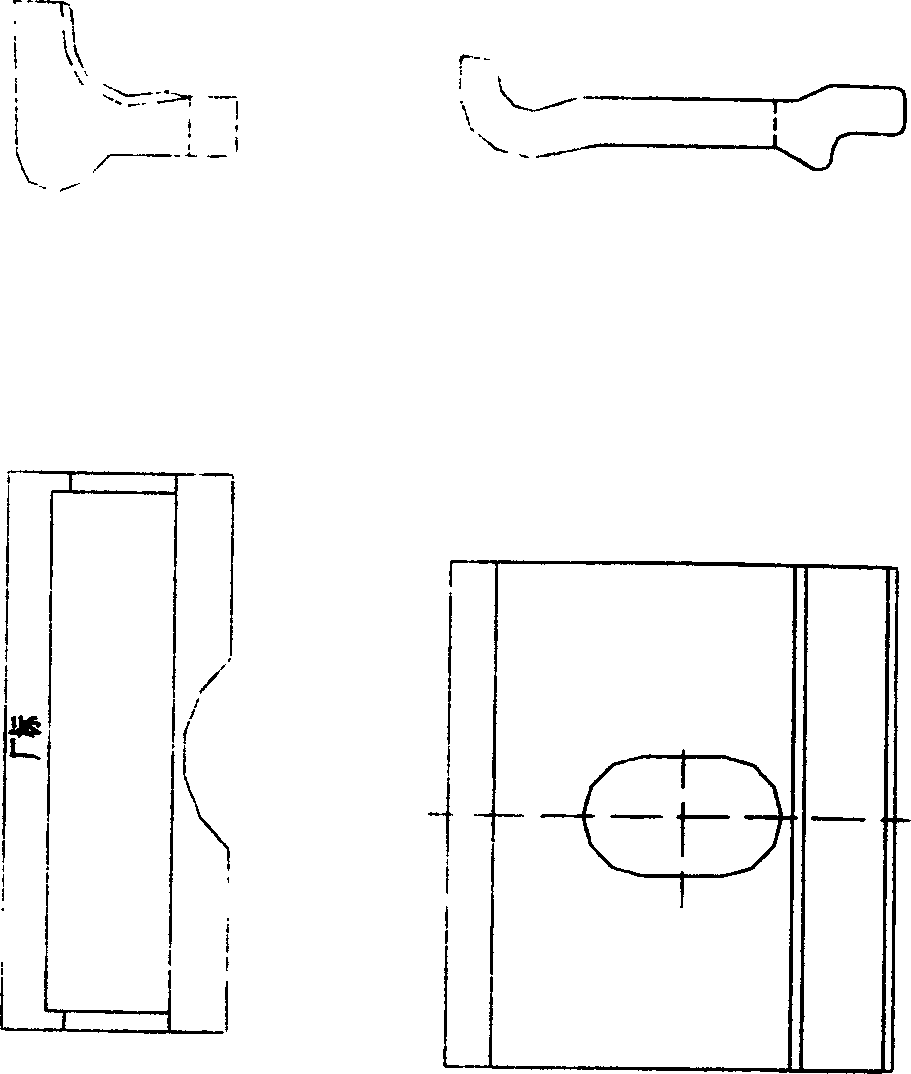

[0038] see image 3: After comparing the advantages and disadvantages of the slope groove and the arc shoulder, the straight slope groove shoulder structure is selected, which includes the structure and material of the threaded spike 1 (and the nut 2, the flat washer 3), the fastener (elastic strip) 4) Gauge adjustment, height adjustment. The height of the concrete from the shoulder to the end of the sleeper is 20mm, and the projection of the shoulder on the front elevation is composed of a slanted line, a vertical line and an arc line, in which the length of the slanted line is 17-18mm, and the length of the vertical line is 29mm. -31mm, the groove depth at the end of the rail groove is 8-10mm, and the width is 17-19mm. The thickened gauge baffle plate 5 is 10mm thick, and the thickness of the rubber backing plate 7 is 14mm. T-shaped baffle plate seat 6 is adopted. The optimum oblique line length of the projection of the shoulder on the front elevation is 17.5mm, and the opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com