Agricultural polyethylene resin composition

A technology of resin composition and polyethylene resin, applied in the field of polyethylene resin composition, can solve the problems of high drawdown of resin, difficult formation of film bubbles, easy accumulation on the wind ring, etc., and achieves high melt strength, rolling tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Raw materials: LLDPE DFDA7042 powder produced by Jilin Petrochemical Company

[0015] LLDPE 103AA powder produced by Lanzhou Petrochemical Company

[0016] Produced by TA Lanzhou Auxiliary Factory

[0017] Antioxidant B561 Produced by Lanhua Organic Factory

[0018] Calcium Stearate Produced by Chongqing Changjiang Chemical Factory

[0019] Preparation of the resin composition:

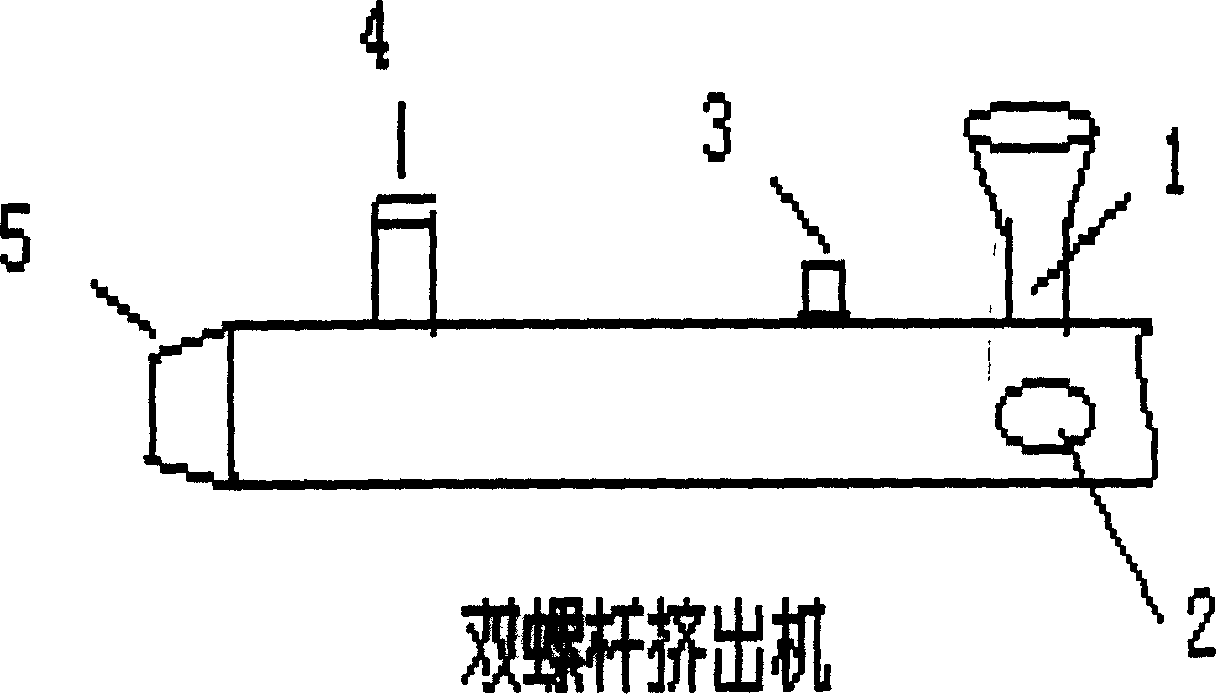

[0020] Using the Φ67 twin-screw extruder produced by German Lestreiz Company as the reactor, LLDPE resin is added from the feeding port 1, B561 and calcium stearate enter the extruder from the side feeding port 2, and TA is added from the liquid dripping port 3 . Reactive devolatilization can be achieved at the exhaust port 4 of the extruder. The reaction materials are finally extruded and granulated by the head 5 to obtain the LLDPE resin composition. The specific raw material formula and preparation process conditions are shown in Table 1 and Table 2.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com