Non-digging and integral repairing method for underground pipeline

A technology for underground pipelines and repair methods, applied to pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as time-consuming, labor-intensive and costly, and achieve the effects of short construction period, fast construction speed, and easy flanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

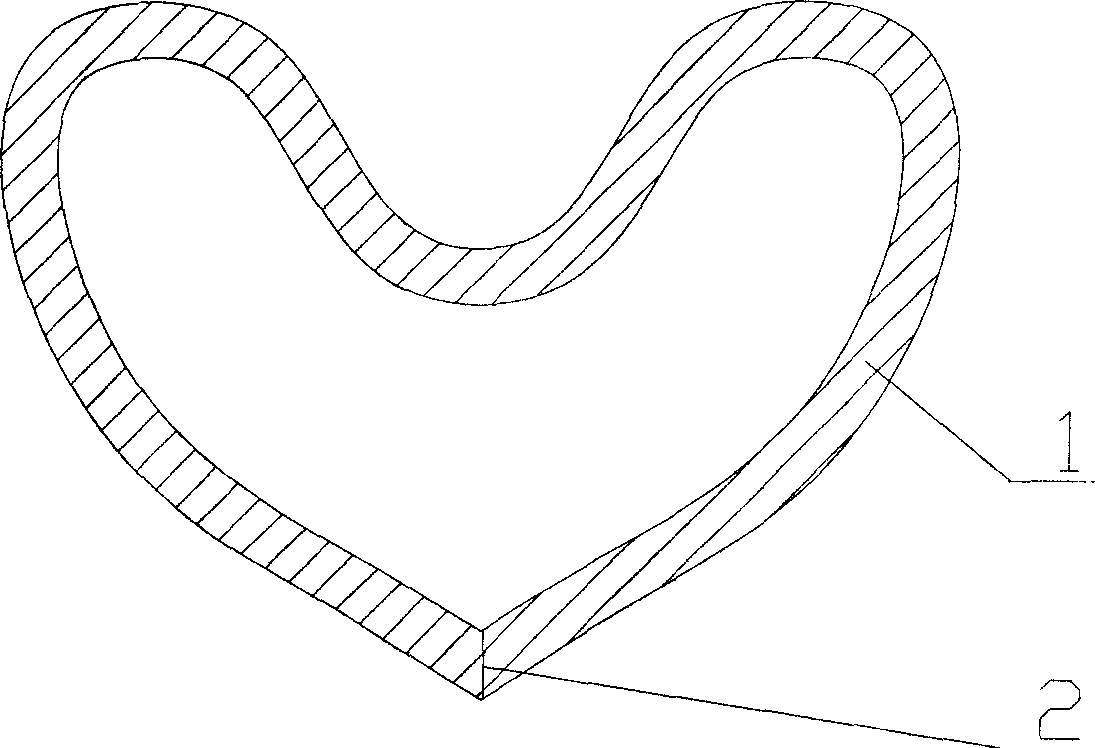

[0019] Embodiment 1, the length of the pipeline to be repaired is 12m, and the inner diameter of the pipeline is 62mm. First, the pipeline is cleaned, and a stainless steel strip with a thickness of 0.2mm and a width of 62πmm is welded into a stainless steel pipe with an argon arc welding seam machine on site; the stainless steel pipe is pressed into a cross section It is a "heart"-shaped tube; one end of the stainless steel tube is flattened and folded back, and a soft steel wire rope slightly longer than the pipe is passed through the folded back, that is, the soft steel wire rope is connected to the stainless steel tube, and the other end of the soft steel rope is connected to the rubber applicator (i.e. pig ) connection, use a blower to transport the rubber applicator (i.e. pig) from one end of the pipe to the other end, that is, bring the soft steel wire rope from one end of the pipe to the other end; pull the soft steel wire rope to put the stainless steel pipe into the pi...

Embodiment 2

[0020] Embodiment 2, the pipeline that needs to be repaired is 300m, and the internal diameter is 120mm. First, the pipeline is cleaned, and the stainless steel strip with a thickness of 0.6mm and a width of 120πmm is welded into a stainless steel pipe with a high-frequency welder on the spot; ”-shaped tube; flatten one end of the stainless steel tube and fold it back, and pass a soft steel wire slightly longer than the pipe through the folded back, that is, the soft steel wire is connected to the stainless steel tube, and the other end of the soft steel wire is connected to the rubber applicator (pig). Use a blower to transport the rubber applicator (i.e. pig) from one end of the pipeline to the other, that is, bring the soft steel wire rope from one end of the pipeline to the other; pull the soft steel rope to put the stainless steel pipe into the pipeline, and seal the two ends of the pipeline , use a pump to pump water into the pipeline, and the water pressure is 10Mpa to r...

Embodiment 3

[0021] Embodiment 3, the pipeline that needs to be repaired is 800m, and the inner diameter is 120mm. First, the pipeline is cleaned, and a stainless steel strip with a thickness of 1 mm and a width of 120πmm is welded into a stainless steel pipe with a high-frequency welder on the spot; the stainless steel pipe is pressed into a cross section of "heart". ”-shaped tube; flatten one end of the stainless steel tube and fold it back, and pass a soft steel wire slightly longer than the pipe through the folded back, that is, the soft steel wire is connected to the stainless steel tube, and the other end of the soft steel wire is connected to the rubber applicator (pig). Use a blower to transport the rubber applicator (i.e. pig) from one end of the pipeline to the other, that is, bring the soft steel wire rope from one end of the pipeline to the other; pull the soft steel rope to put the stainless steel pipe into the pipeline, and seal the two ends of the pipeline , use a pump to pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com