Cement asphalt mortar in use for ballastless track in railroad or city light rail, as well as fabricating method and construction method

A technology of ballastless track and cement asphalt, which is applied in the field of cement asphalt mortar for railway or urban light rail ballastless track and its manufacture and construction, can solve the problems of long working time and volume expansion, and achieve the effect of excellent vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

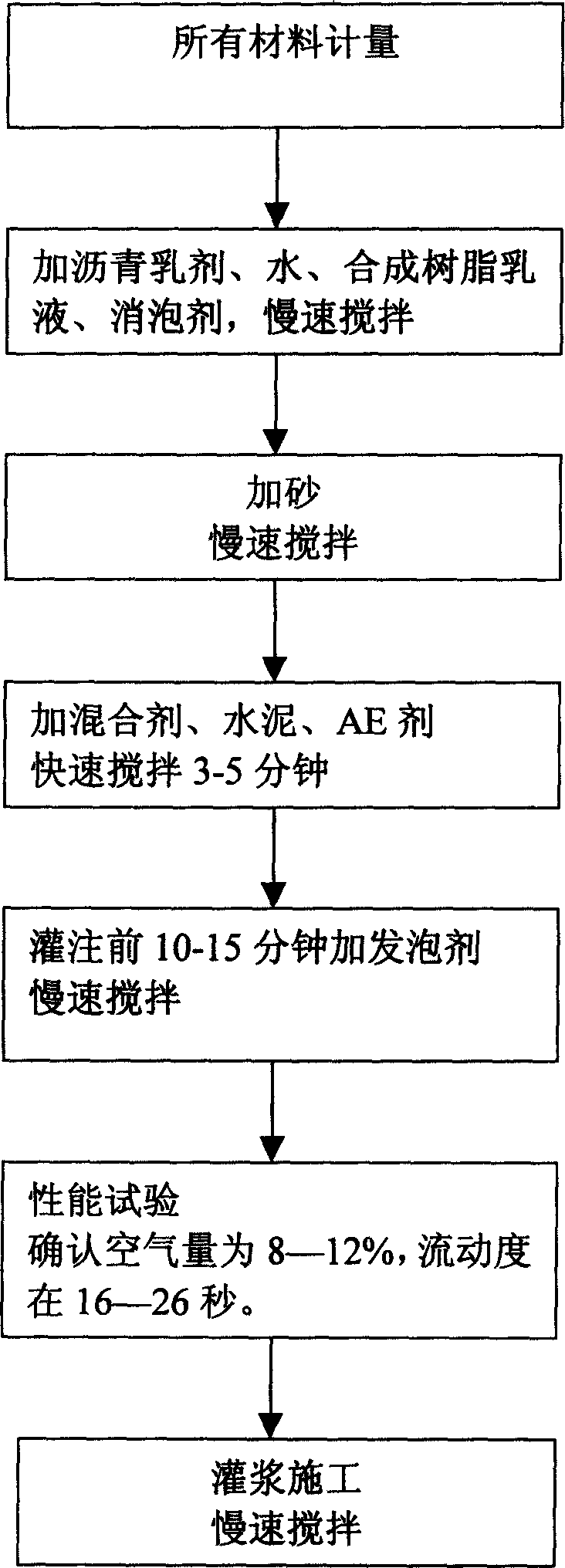

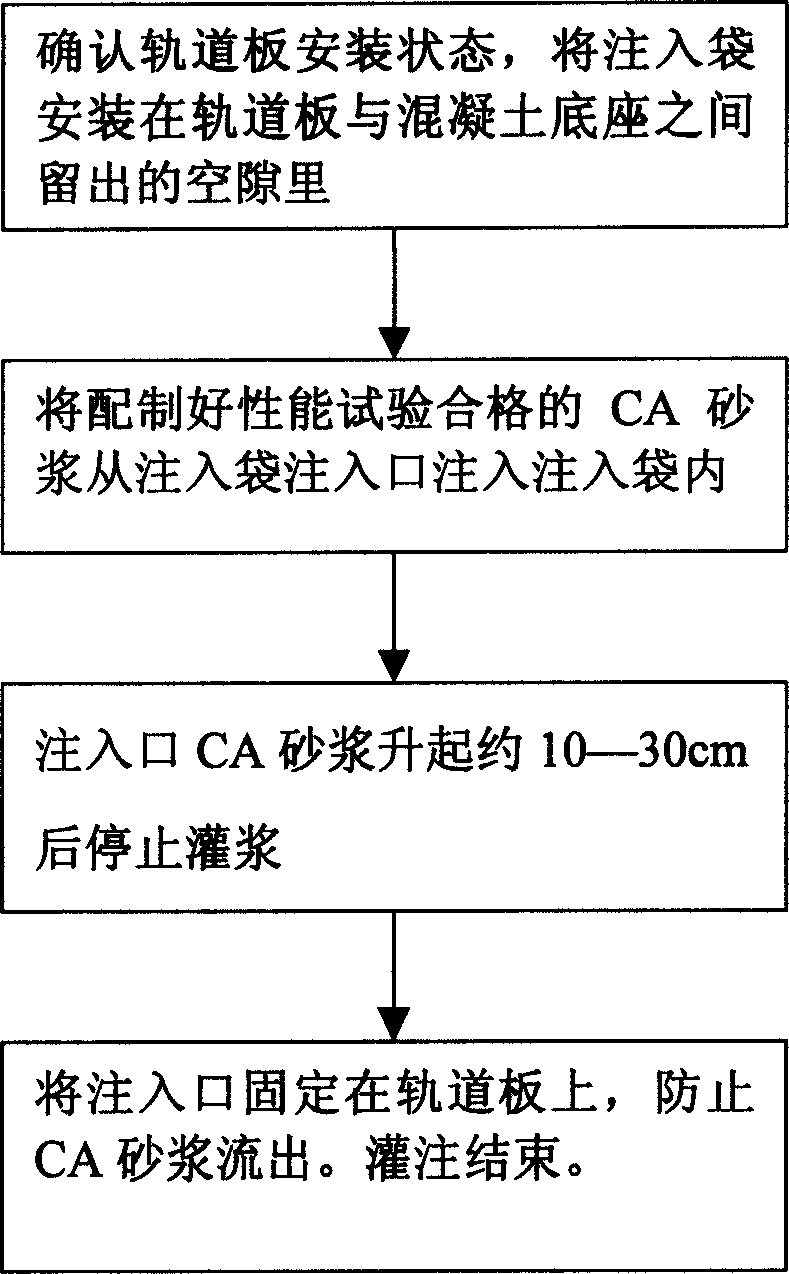

Method used

Image

Examples

Embodiment 1--4

[0033] The CA mortar of embodiment 1-4 is prepared according to the mixing ratio of following (table 1) (parts by mass, the same below):

[0034] implement

[0035] in:

Embodiment 1

[0036] The asphalt emulsion of embodiment 1 is nonionic; The asphalt emulsion of embodiment 2 is cationic; The asphalt emulsion of embodiment 3 is anionic; The asphalt emulsion of embodiment 4 is the composite of anion and nonionic asphalt emulsifier and then various asphalts (straight-run asphalt, oxidized asphalt, asphalt composition, petroleum asphalt, coal tar pitch) and nonionic polymers are dispersed in this composite emulsifier to form a uniform and stable emulsifier that meets the requirements of the present invention. Composite emulsion, and the non-ionic polymer in the asphalt emulsion can be one or a mixture of polyacrylic acid, polyurethane, polyvinyl acetate, etc. Its main function is to increase the resin content in the asphalt emulsion, increase the viscosity, and form the so-called emulsion. Polymers play a big role in preventing delamination of CA mortar materials and reducing the amount of added water.

[0037] The cements of Examples 1-4 can be used alone o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com