Cooling machine high-temp fixed bed anti-stack device for industrial furnace

An anti-accumulation and cooling machine technology, applied in the direction of furnaces, furnace components, processing discharged materials, etc., can solve problems such as shortening the life of refractory bricks, affecting the operating life of equipment, and production loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

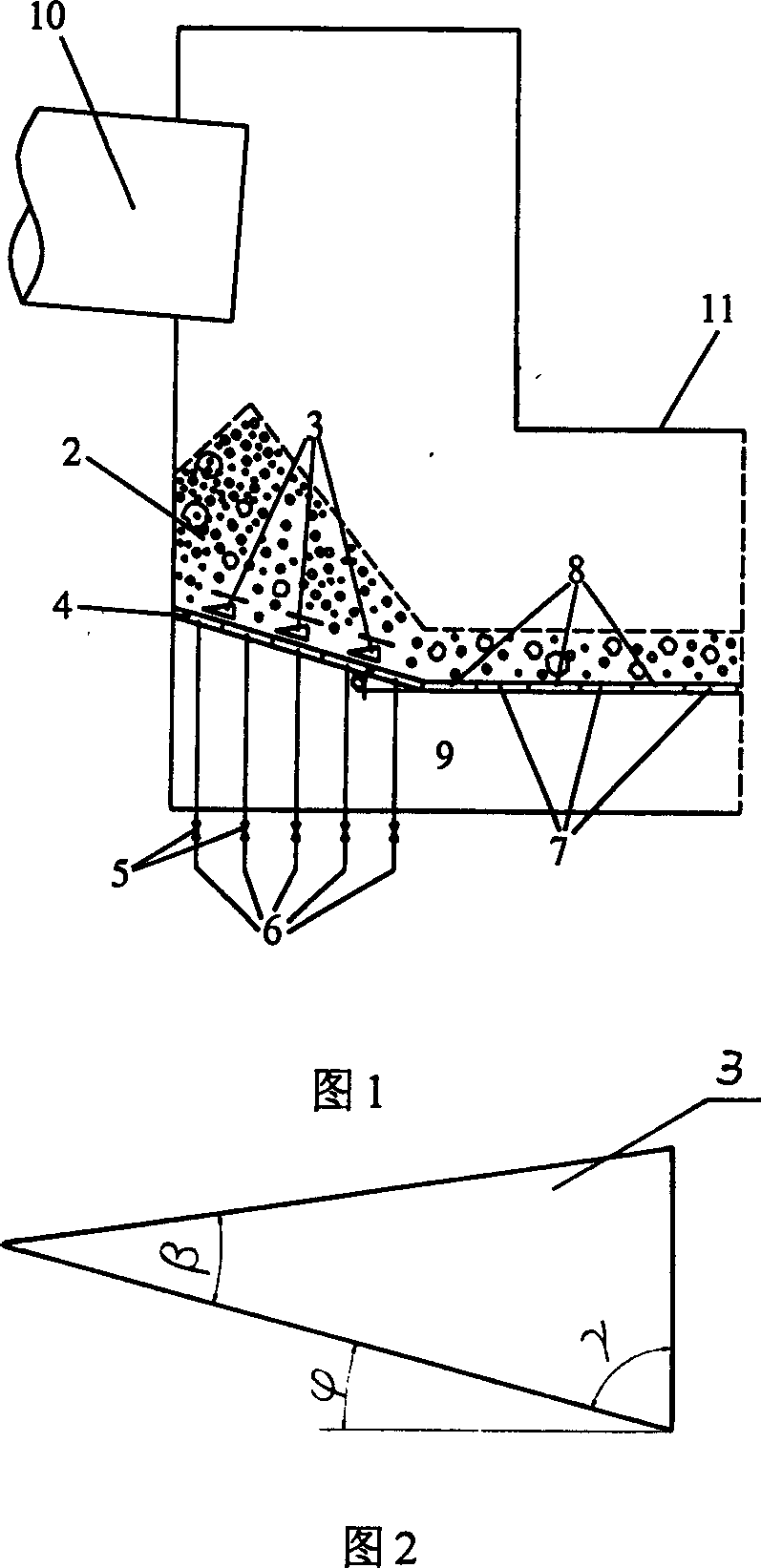

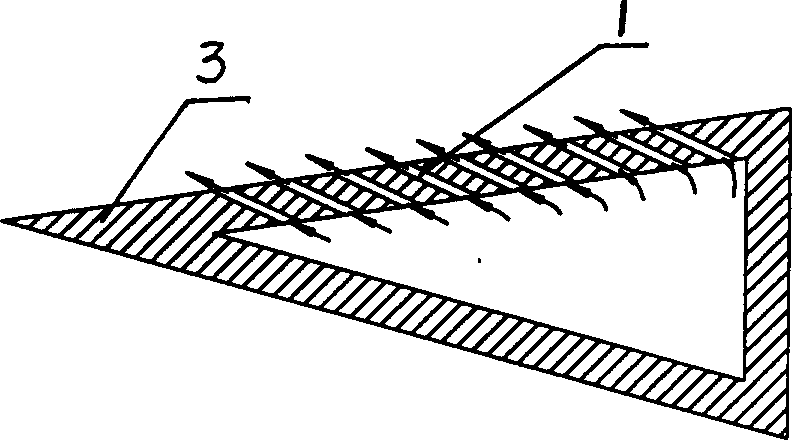

[0024] Figure 1- Figure 9 As shown, the present invention relates to a device capable of eliminating continuous cooling of high-temperature block or granular materials "snowman" sintered through industrial kilns 10 (such as cement rotary kilns), which includes walls 11, high-temperature fixed bed grate plates 4 , cooling gas pipeline 6, cooling gas regulating valve 5, fixed grate plate 8 on movable bed and movable grate plate 7, air supply air chamber 9. At least one high-temperature grate bed anti-accumulation device 3 that can reciprocate and / or vibrate and / or rotate and / or swing is arranged above the fixed bed grate plate 4, and the high-temperature grate bed anti-accumulation device 3 facilitates the movement of materials and cool. Although the fixed bed grate plate of the traditional cooling machine also has three functions of supporting the material to be cooled, distributing the cooling gas into the material bed, and conveying the material, but because the fixed bed g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com