Strong force propulsion plant of continuous tube

A propulsion device and coiled tubing technology, applied in directional drilling, drilling with liquid/gas jets, etc., can solve the problems of difficulty in completing near-horizontal deep drilling construction, small contact area, small propulsion force, etc., and achieve improved propulsion. force, increase the propulsion friction surface, increase the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

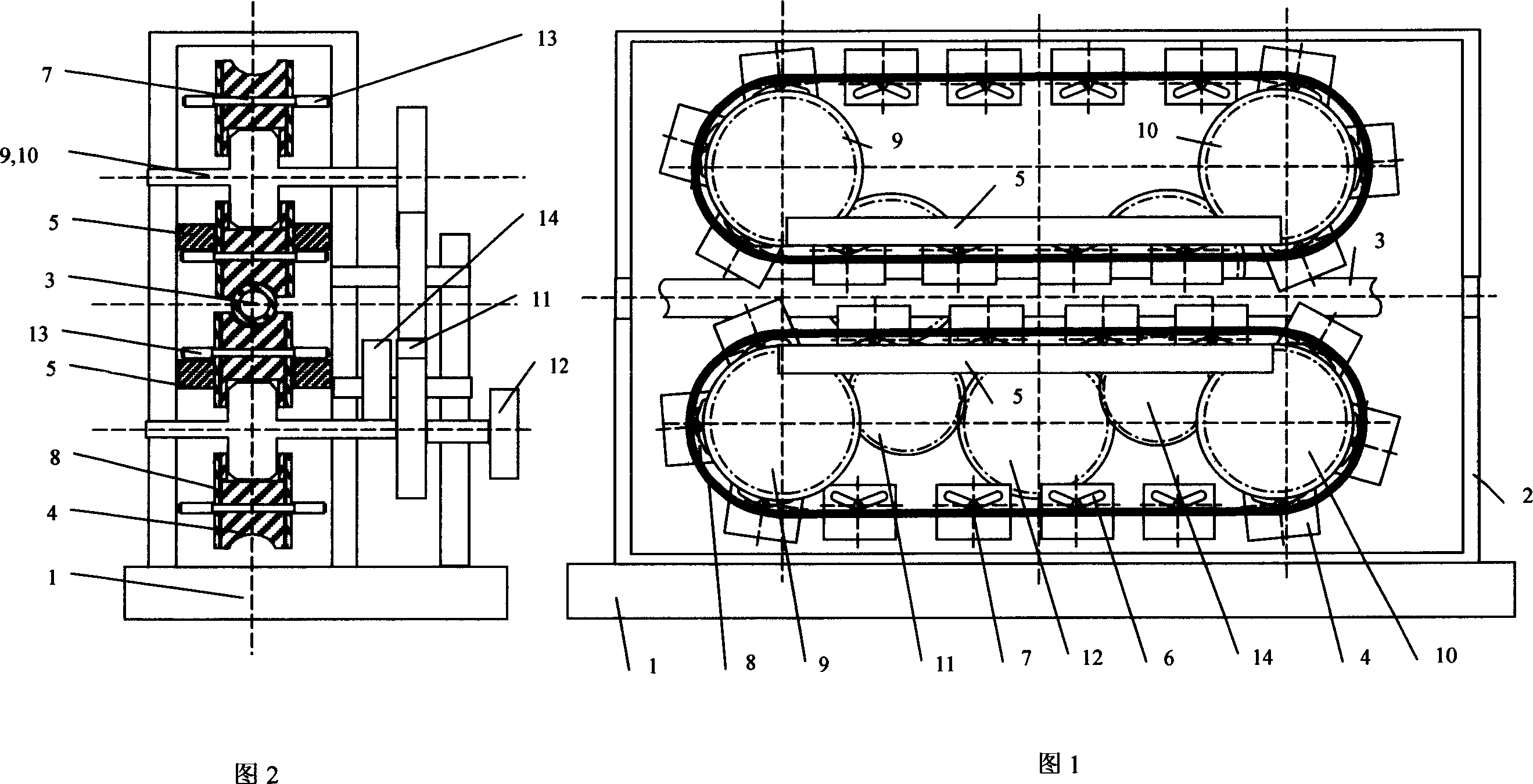

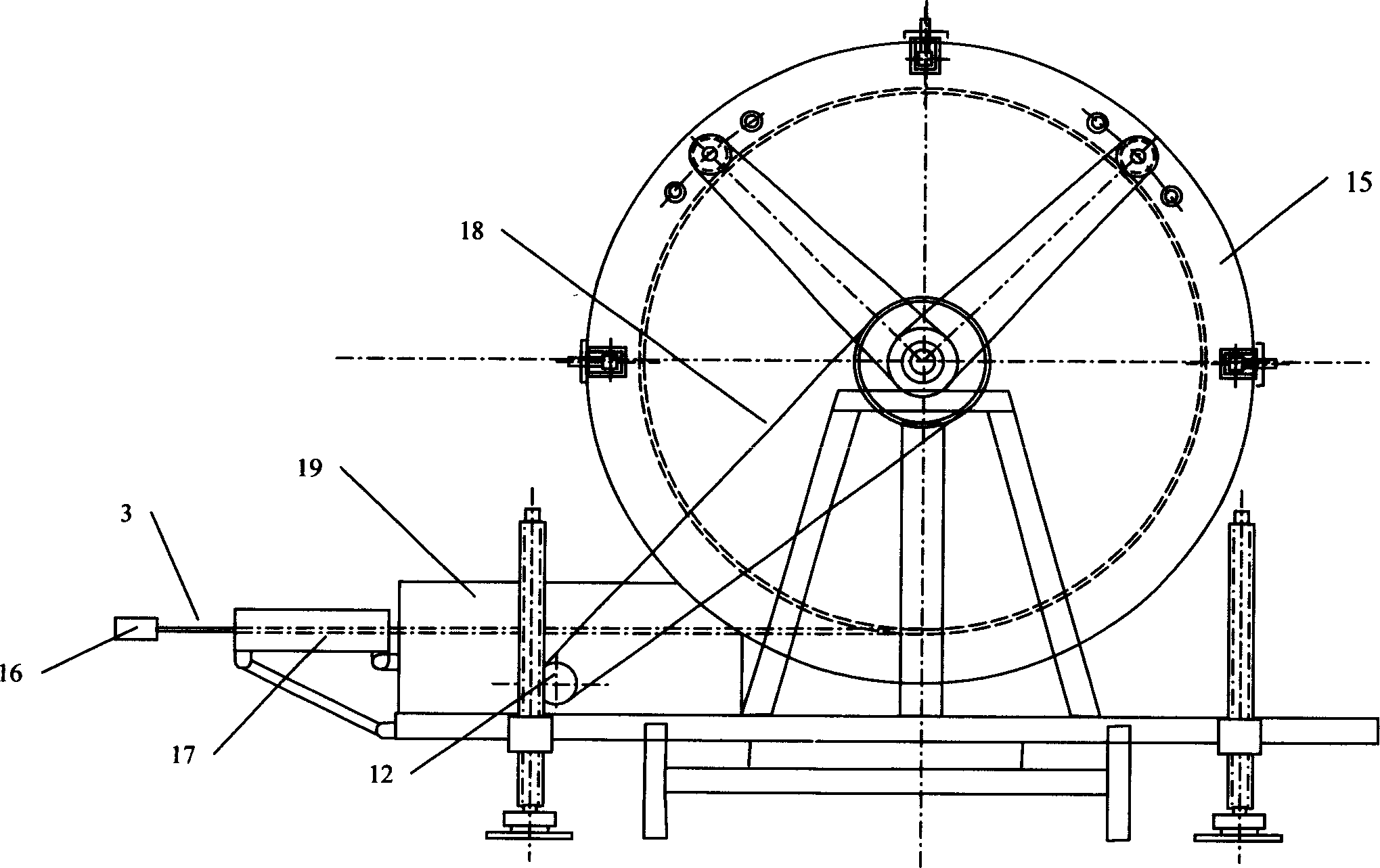

[0018] As shown in Figures 1 and 2, a powerful propulsion device for coiled tubing includes countermoving friction members arranged symmetrically up and down on the continuous pipe 3, and the friction members are a pair of closed On the transmission chain 8, evenly distributed and fixed friction blocks 4, each friction block 4 is connected with the transmission chain 8 through a shaft pin 7, and each friction block 4 is provided with an oblique track 6 of the shaft pin 7, in the continuous tube 3 The two limit rails 5 fixed up and down symmetrically are parallel to the continuous tube 3, and the rollers 13 installed at both ends of the shaft pin roll on the limit rails, and each transmission chain 8 is driven by the forward drive wheel 9 or the reverse drive wheel 10 , the main driving wheel 12 connected with the drilling rig drives the forward driving wheel 9 through the forward driving reversing wheel 11; or the main driving wheel 12 drives the reverse driving wheel 10 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com