Technology for sintering luminescent powder on the surface of ceramic and glass products

A technology for glass products and phosphor powder is applied in the field of sintering phosphor powder on the surface of ceramics and glass products. High luminous brightness, non-radioactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

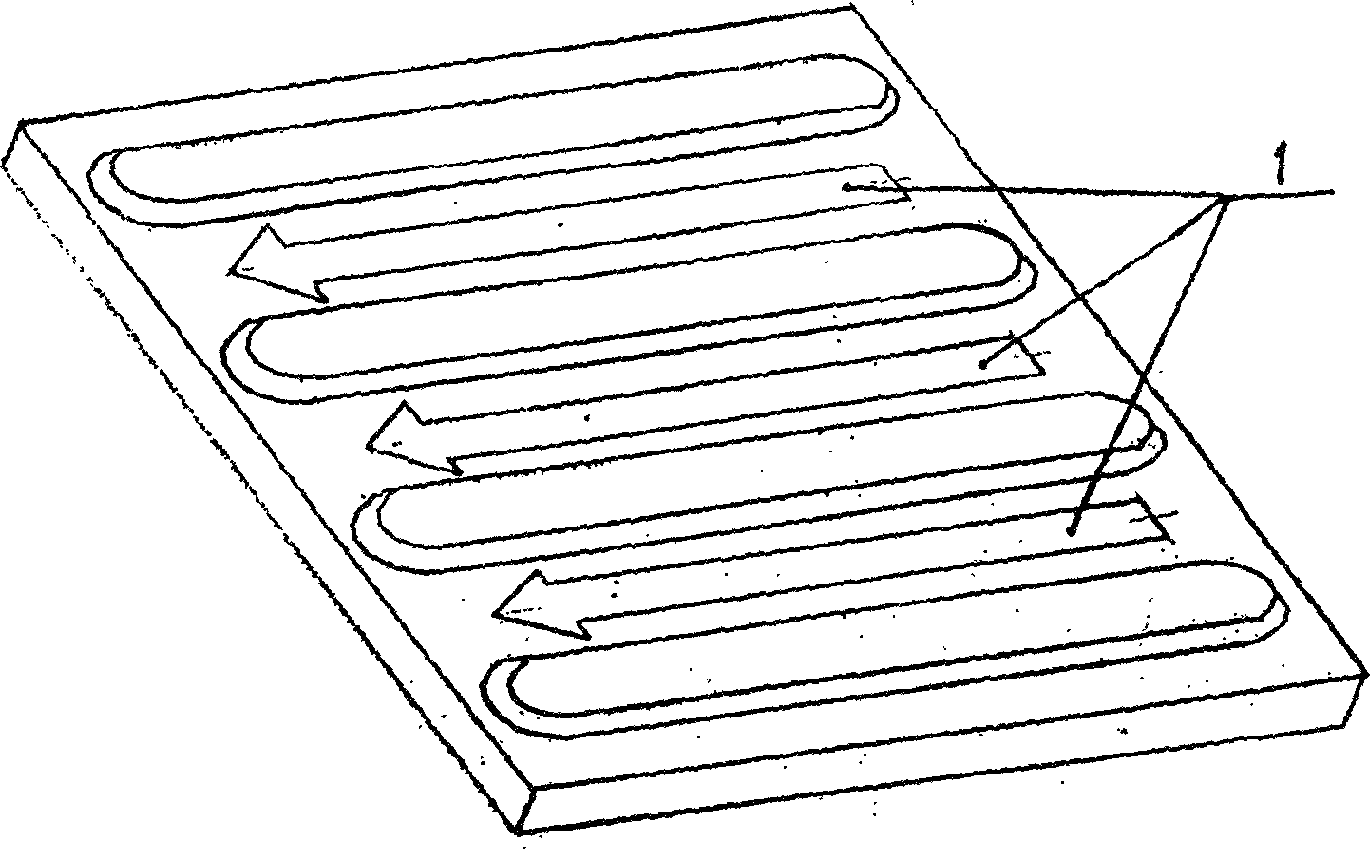

[0030] Example 1: Making light-emitting strips on guide bricks ( figure 1 )

[0031] Its process (dry method) steps are:

[0032] 1) Add frit powder with a fineness of 150 mesh to the phosphor powder with a fineness of 150 mesh, in which the phosphor powder accounts for 75% and the frit powder accounts for 25%, and the two are mixed evenly in proportion to prepare a luminescent powder.

[0033] 2) Use a thin plate to make two bushings with the same shape of the hollow part, and the shape of the hollow part is figure 1 The shape of the light-emitting portion 1 shown is a rectangular bar shape with an arrow. The production method of the leakage plate: press the metal or plastic thin plate with a 1mm drill bit figure 1 The shape of the light-emitting part 1 shown, punch out evenly arranged small holes, so that countless small holes are arranged on the thin plate figure 1 The shape of the luminous part 1 shown, made with figure 1 Leakage plate in the shape of the light-emitti...

Embodiment 2

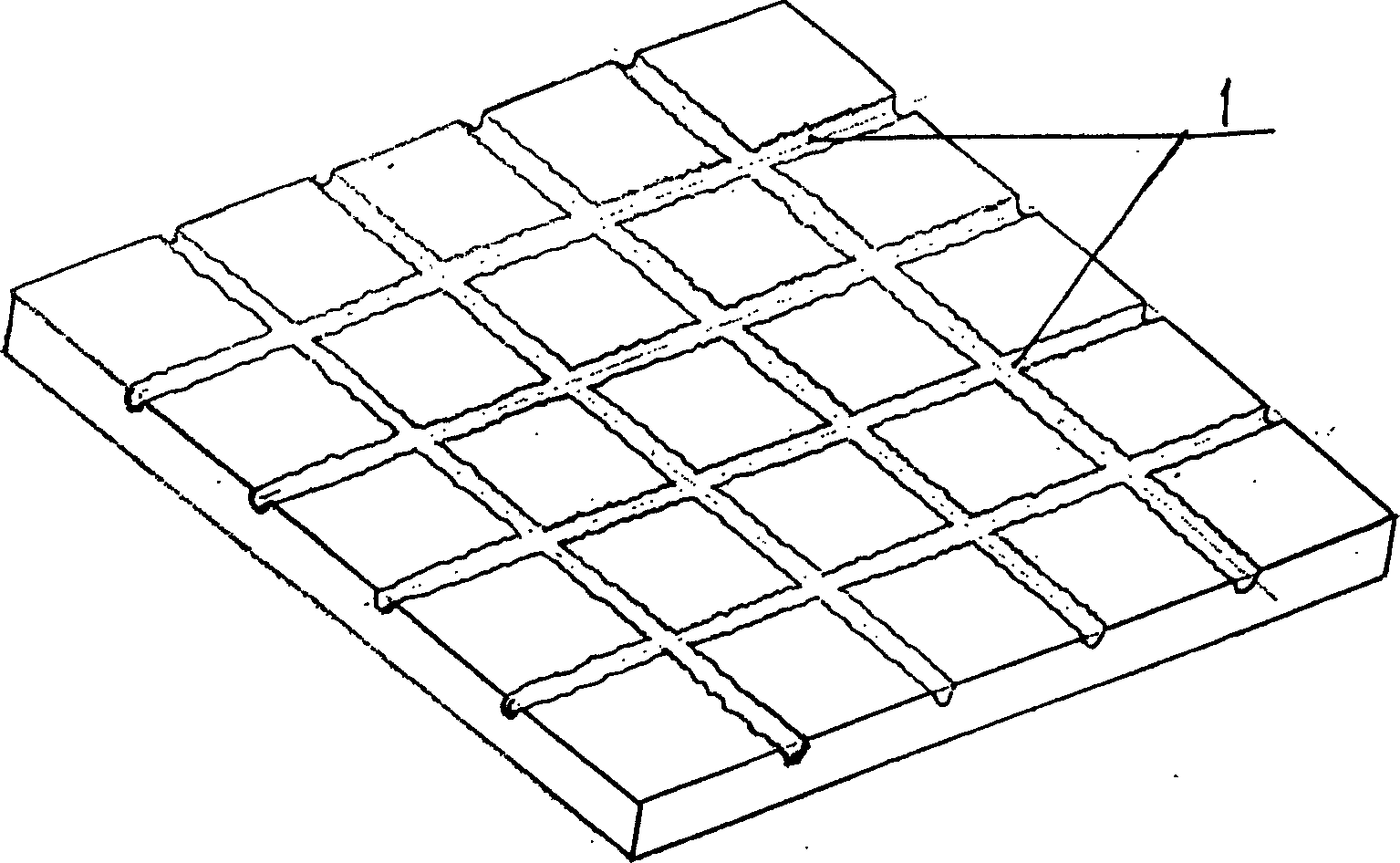

[0038] Example 2: Making luminous anti-skid bricks ( image 3 )

[0039] Its process (dry method) steps are:

[0040] 1) Add frit powder with a fineness of 150 mesh to the phosphor powder with a fineness of 150 mesh, in which the phosphor powder accounts for 70% and the frit powder accounts for 30%, and the two are mixed evenly in proportion to prepare a luminescent powder.

[0041] 2) Made on the surface of the brick image 3 As shown in the groove, the groove is used as the light-emitting part 1, and the depth of the groove is 5mm.

[0042]3) Fill the luminous powder into the groove with a thickness of 3mm, and this layer is the luminescent layer of the luminous part 1 of the brick. Then, the surface of the luminescent powder is coated with frit powder with a thickness of 1 mm, which is the protective layer of the luminous part 1 of the brick. In this way, the light-emitting part 1 is 1 mm lower than the surface of the brick, which can play an anti-slip effect.

[0043]...

Embodiment 3

[0045] Example 3: Making a luminous pattern on a glass ( Figure 4 )

[0046] Its process (wet method) steps are:

[0047] 1) Mix 20-30 parts of phosphor powder with a fineness of 250 mesh, 3-5 parts of additives, and 65-75 parts of water in proportion to make a luminous glaze.

[0048] Wherein the filler can be dextrin, bone glue, methyl cellulose and the like.

[0049] 2) Take 50-60 parts of frit powder with a fineness of 100 meshes, 0.1-0.3 parts of sodium tripolyphosphate, 3-7 parts of methyl cellulose, 35-38 parts of water, add in a ball mill for internal grinding, Pass through a 150-mesh sieve to make glaze paste.

[0050] 3) in Figure 4 According to the required light-emitting part 1, the required light-emitting pattern is engraved on the surface of the glass cup 4, the depth is 1.5mm, and the light-emitting glaze is drawn into the carved pattern by spraying, hand-painting, etc., so that the thickness of the light-emitting glaze is 0.5mm. This layer is the light-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com