Selenium enriched liquid fertilizer and public hazard less production method of selenium enriched aqgricultural product thereof

A production method and technology of agricultural products, applied in fertilization methods, applications, agriculture, etc., can solve problems such as environmental pollution, and achieve the effects of overcoming environmental pollution, simple production, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

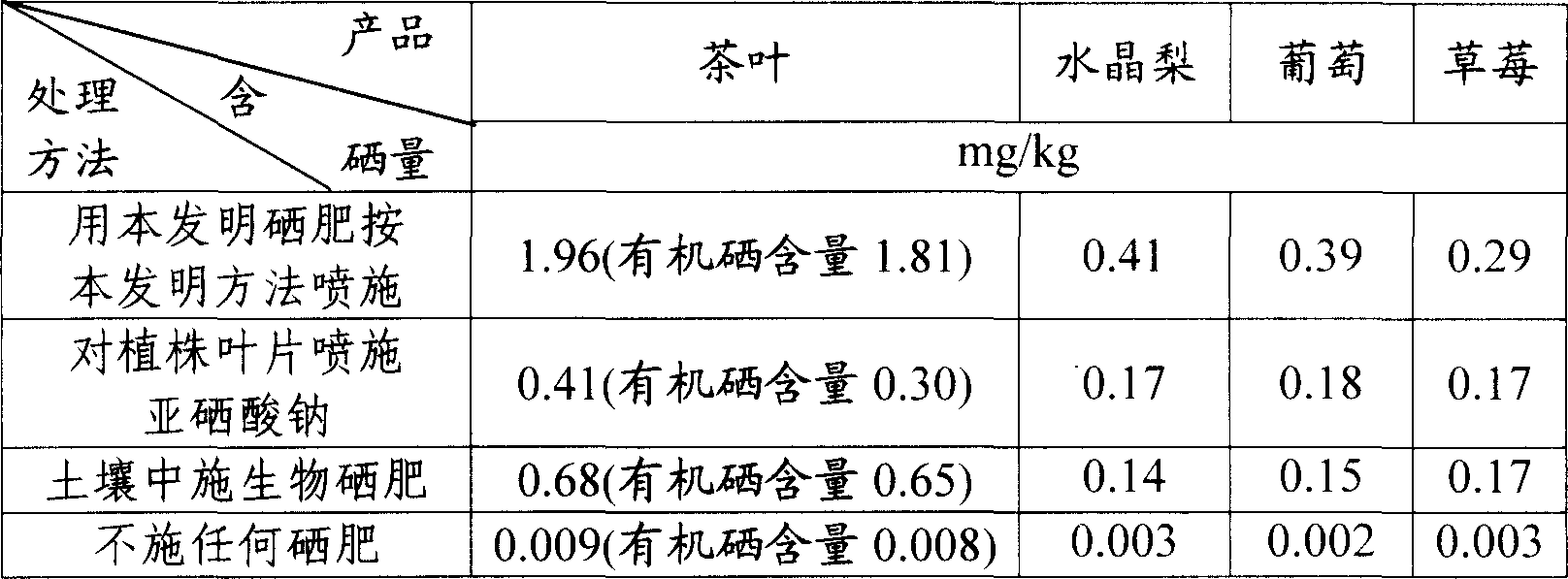

Examples

Embodiment 1

[0017] First produce selenium-enriched liquid fertilizer according to the following steps:

[0018] (1) According to the weight ratio, add 1 part of pig, sheep, cattle and other stable manure to 10 parts of water, and after natural storage for 8 months, filter it through 200 mesh to obtain the filtrate.

[0019] (2), by weight, with 1 part of sodium selenite, add 50 parts of filtrate, stir evenly, carry out natural biological fermentation at a temperature of 21° C. for 25 days to obtain selenium-enriched liquid fertilizer.

[0020] The production method of using this selenium-enriched liquid fertilizer for selenium-enriched agricultural products is to dilute 1 part of selenium-enriched liquid fertilizer with 500 parts of water (by weight), and spray it on the plants after 15:00 when there is no wind before the agricultural products are harvested. Behind the leaves, and does not form water droplets on the ground.

Embodiment 2

[0022] First produce selenium-enriched liquid fertilizer according to the following steps:

[0023] (1) According to the weight ratio, add 1 part of pig, sheep, cattle and other stable manure to 8 parts of water, and after natural storage for 6 months, filter it through 100 mesh to obtain the filtrate.

[0024] (2), by weight, with 1 part of sodium selenite, add 50 parts of filtrate, stir evenly, carry out natural biological fermentation at a temperature of 28°C for 20 days to obtain selenium-enriched liquid fertilizer.

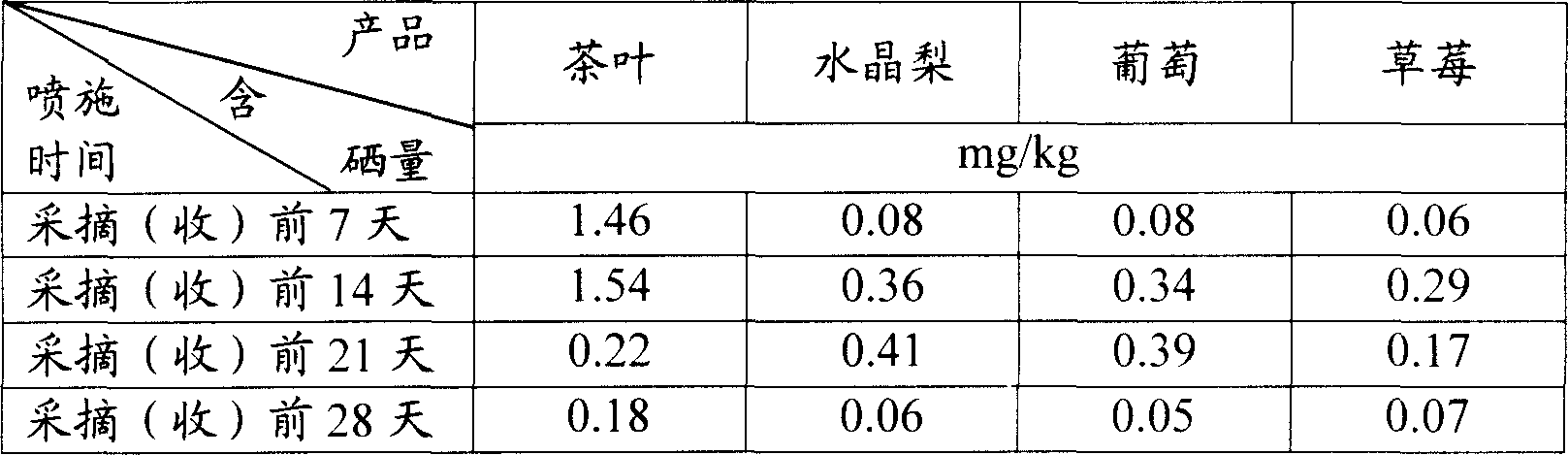

[0025] This selenium-enriched liquid fertilizer is used for the pollution-free production method of selenium-enriched tea, after 1 part of selenium-enriched liquid fertilizer is diluted with 400 parts of water (by weight), spray 50kg on the tea tree per mu, and focus on the back of the blade, and do not Form water droplets on the ground. They were sprayed 7 days, 14 days, 21 days, and 28 days before tea mining. The selenium content in tea is shown in Table ...

Embodiment 3

[0027] First produce selenium-enriched liquid fertilizer according to the following steps:

[0028] (1) According to the weight ratio, 1 part of manure such as pigs, sheep and cattle, and 14 parts of water are added, and after natural storage for 8 months, it is filtered through 300 mesh to obtain the filtrate.

[0029] (2), by weight, add 1 part of sodium selenite and 50 parts of filtrate, stir well, and carry out natural biological fermentation at a temperature of 25°C for 30 days to obtain selenium-enriched liquid fertilizer.

[0030] This selenium-enriched liquid fertilizer is used in the pollution-free production method of selenium-enriched pears, after 1 part of selenium-enriched liquid fertilizer is diluted with 500 parts of water (by weight), spray 60kg per mu on the pear tree, focus on the back of the blade, and Does not form water droplets on the ground. They were sprayed 7 days, 14 days, 21 days, and 28 days before the crystal pears were picked. See Table 2 for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com