Three-dimensional annular braided composite material tube and mandrel separation system and method thereof

A composite material tube and annular braiding technology, applied in the directions of braids, textiles and papermaking, can solve the problems of insufficient length of the mandrel under force, the wall thickness of the hollow mandrel, reduced efficiency, and other problems, so as to overcome the cost increase and make up for the efficiency. Low, overcoming the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

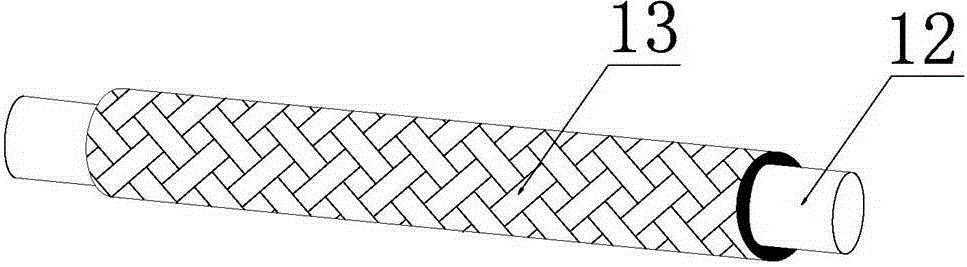

[0026] Please refer to the attached figure 1 , 2 , 4, and 6, the present invention is a three-dimensional annular braided composite tube and mandrel separation system, which is used to separate the braided composite tube from the mandrel, wherein the mandrel can be a solid mandrel 12 , a braided composite tube 13 is formed on the solid mandrel 12 .

[0027] The three-dimensional circular braided composite tube and mandrel separation system consists of a fixed base 1, a mandrel clamping front baffle 2, a mandrel clamping rear baffle 14, a servo motor 3, a reduction transmission mechanism 10, and a pulling stud 11 and other parts.

[0028] Wherein, the mandrel clamping front baffle 2 and the mandrel clamping rear baffle 14 are installed on the fixed base 1 respectively. The solid mandrel 12 is supported on the mandrel clamping front baffle 2 and the mandrel clamping rear baffle 14; the braided composite tube 13 abuts on the mandrel clamping front baffle 2 and the mandrel clam...

Embodiment 2

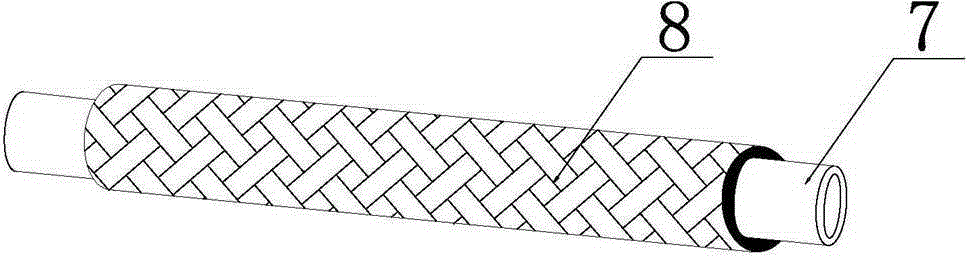

[0036] Please refer to the attached figure 1 , 3 , 5, and 6, the present invention is a three-dimensional annular braided composite tube and mandrel separation system, which is used to separate the braided composite tube from the mandrel, wherein the mandrel can be a hollow mandrel 7 , a braided composite tube 8 is formed on the hollow mandrel 7 .

[0037] The three-dimensional annular braided composite tube and mandrel separation system consists of a fixed base 1, a mandrel clamping front baffle 5, a mandrel clamping rear baffle 6, a servo motor 3, a reduction transmission mechanism 10, and a pulling stud 11 and other parts.

[0038] Wherein, the mandrel clamping front baffle 5 and the mandrel clamping rear baffle 6 are installed on the fixed base 1 respectively. The hollow mandrel 7 is supported on the mandrel clamping front baffle 5 and the mandrel clamping rear baffle 6; the braided composite tube 8 abuts on the mandrel clamping front baffle 5 and the mandrel clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com