Surface processing apparatus

A technology for surface treatment devices and treatment chambers, which is applied in the direction of irradiation devices, exposure devices for photolithography, electrical components, etc., can solve problems such as the complexity of the structure of surface treatment devices, and achieve the effects of improving surface treatment efficiency and simplifying structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

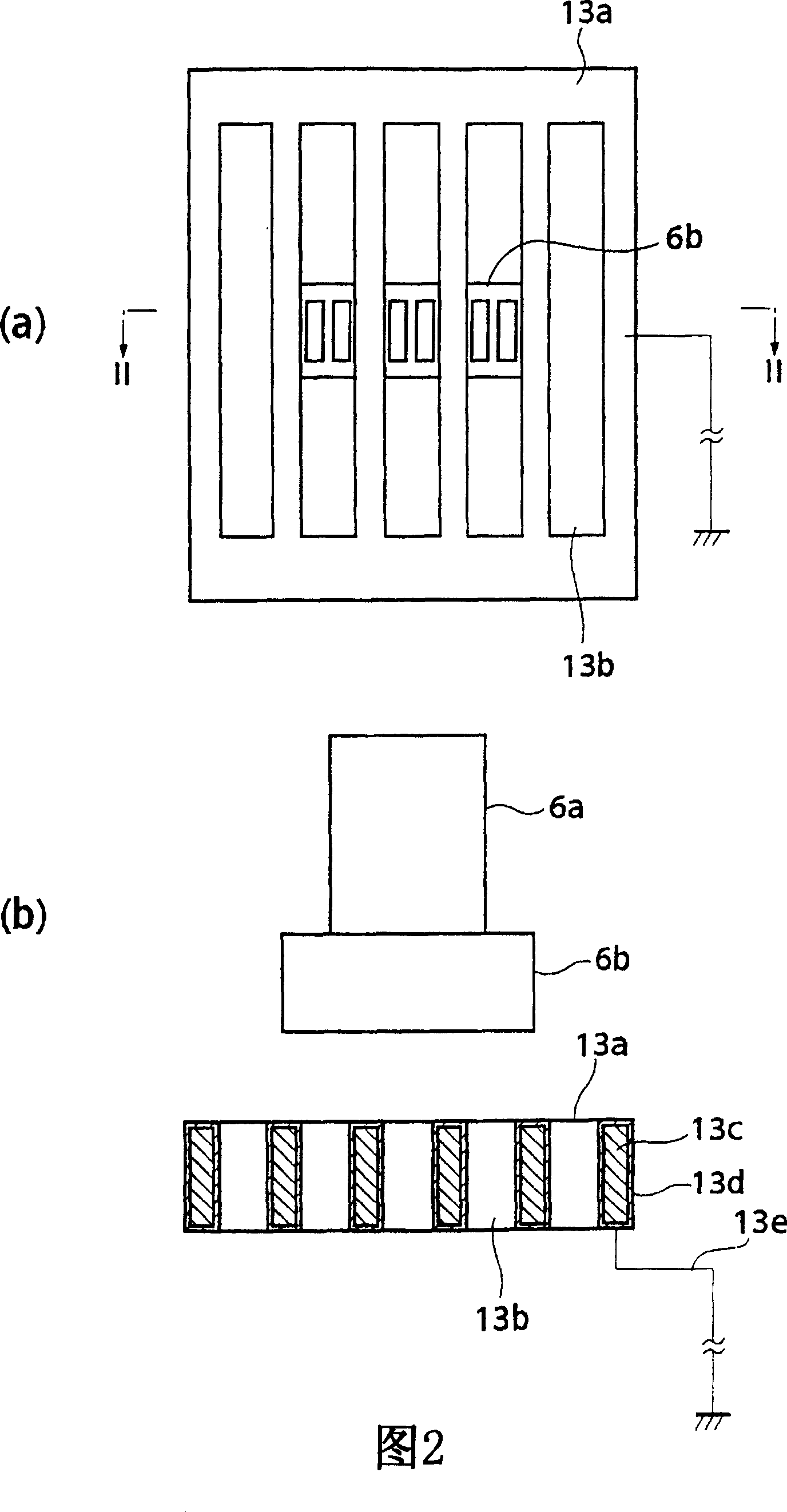

[0052] Next, an object surface treatment device according to a first embodiment of the present invention will be described with reference to the drawings.

[0053] figure 1 A schematic configuration diagram showing a surface treatment device according to a first embodiment of the present invention. This surface treatment apparatus irradiates electron beams to a semiconductor wafer W or the like as an object to be processed, and performs curing treatment (surface treatment) to improve the mechanical strength of the resist.

[0054] exist figure 1 Among them, the surface treatment device 1 includes: a material such as aluminum, etc., whose interior is constituted as a cylindrical vacuum chamber 2 (processing chamber) that can be airtightly closed; disposed inside the vacuum chamber 2, and the semiconductor wafer W The surface to be processed faces the mounting table 3 on which the semiconductor wafer W is placed substantially horizontally at the top of the figure; it is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com