A conical surface electrical connection technique

A technology of electrical connection and technology, which is applied in the field of electrical connection by using a tapered surface, can solve problems such as failure and increase in contact resistance, and achieve the effects of shortening length, reducing contact resistance and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

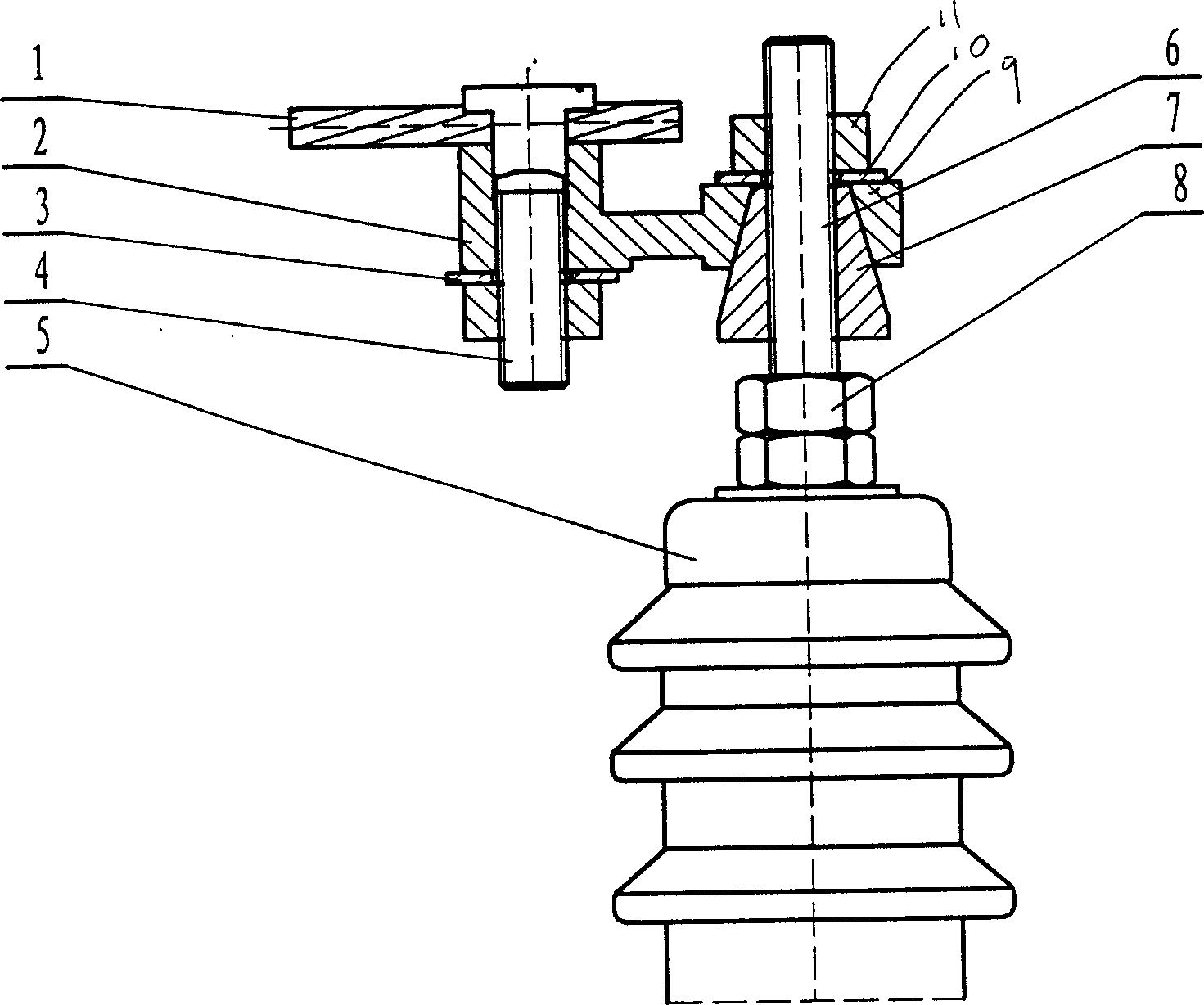

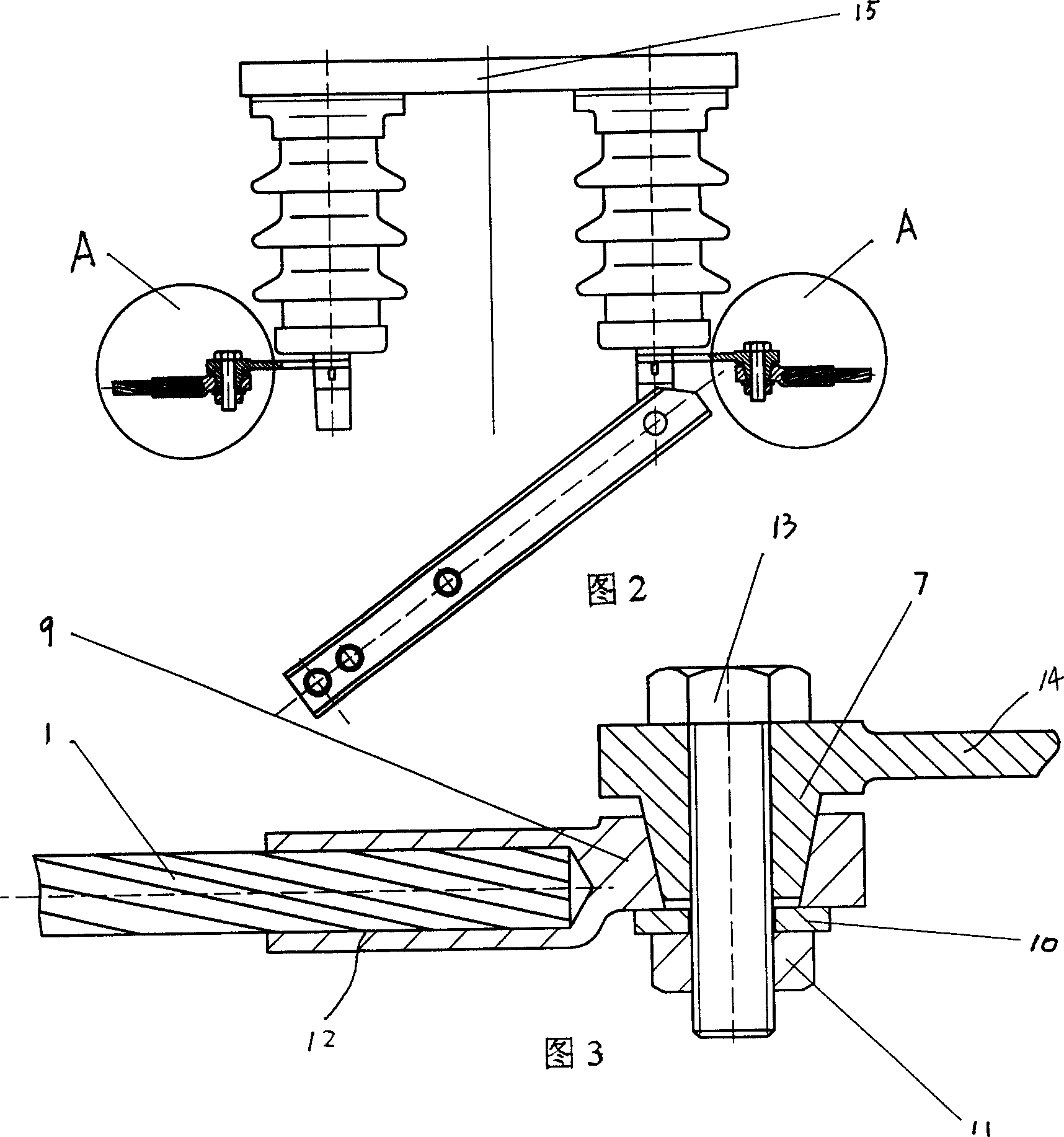

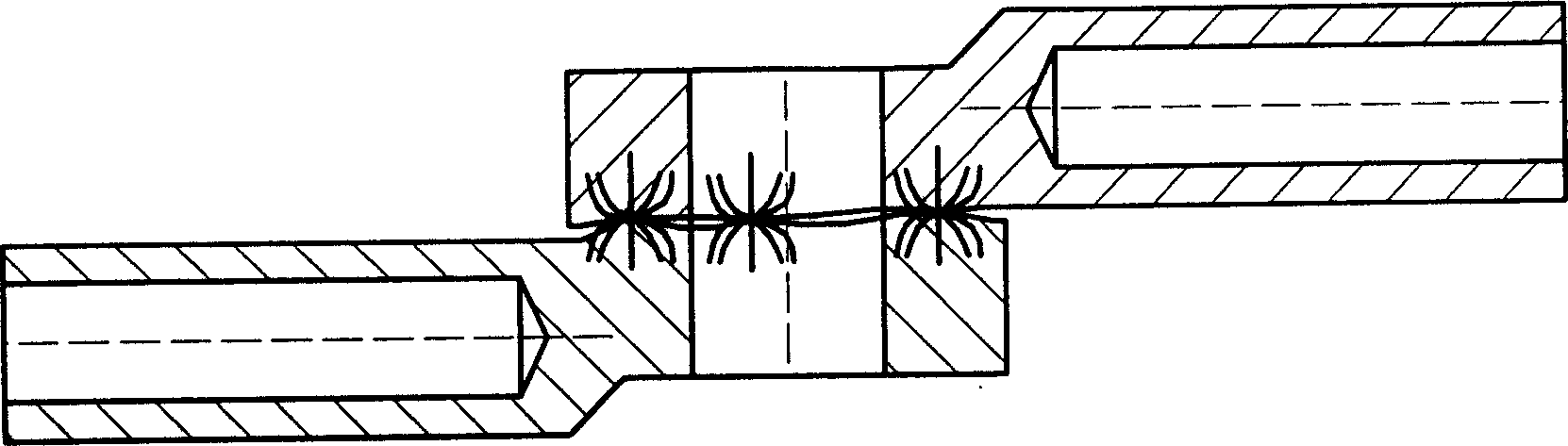

[0016] The electrical connector is composed of an outer taper sleeve joint 9 and an inner taper sleeve joint 7. The contact surface between the inner and outer taper sleeves is a tapered surface. The inner taper sleeve joint 7 is provided with an internal thread. The inner taper sleeve joint 7 uses the thread and The connecting piece of external thread is connected, and the outer taper sleeve joint 9 is sleeved on the outside of the inner taper sleeve joint 7 and fastened together by a nut 11 matched with the connecting piece. This kind of tapered surface will become tighter and tighter when the screw is used to tighten, so that the entire electrical surface is in close contact with the whole, so that the length of the current flow line can be shortened, the current distribution is more uniform and comprehensive, and the contact caused by contact is completely eliminated. Potential accidents such as heat generation of the joints caused by defects, and improve the safety of electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com