Method and apparatus for monitoring grain output and flow rate of complete harvester

A technology of combine harvester and monitoring device, which is applied in the direction of harvester, measuring device, weighing, etc., and can solve problems such as difficult installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

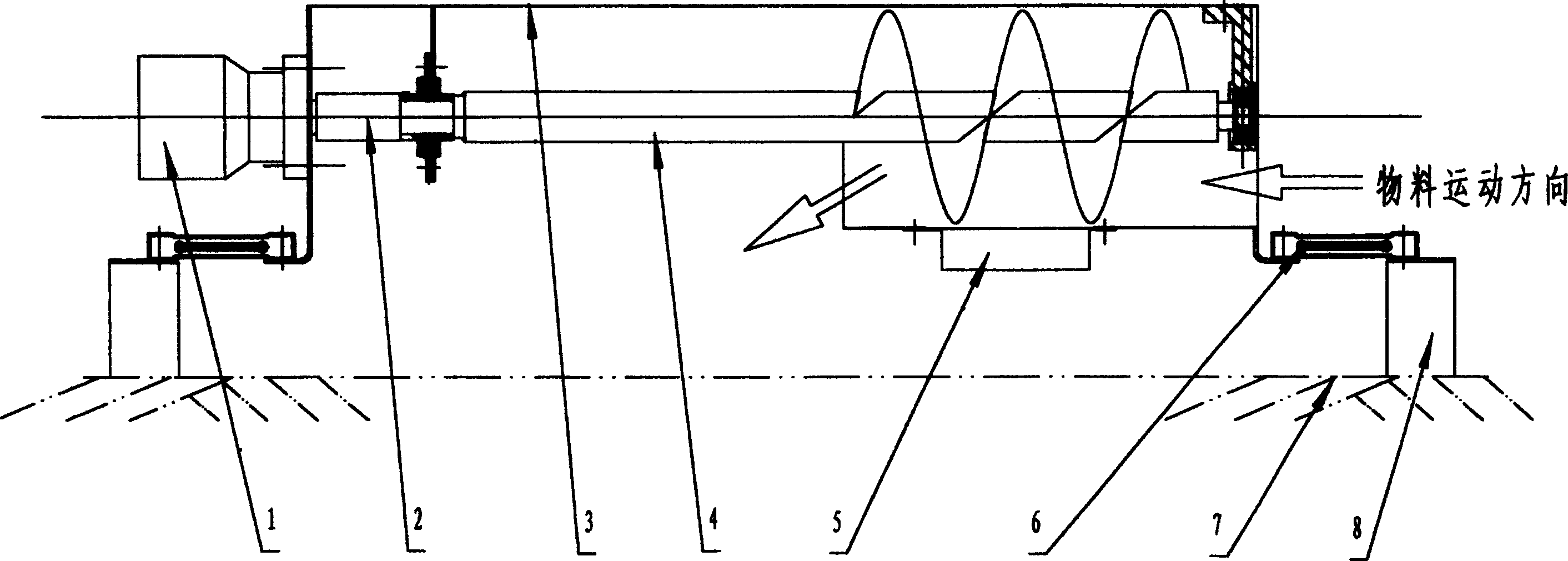

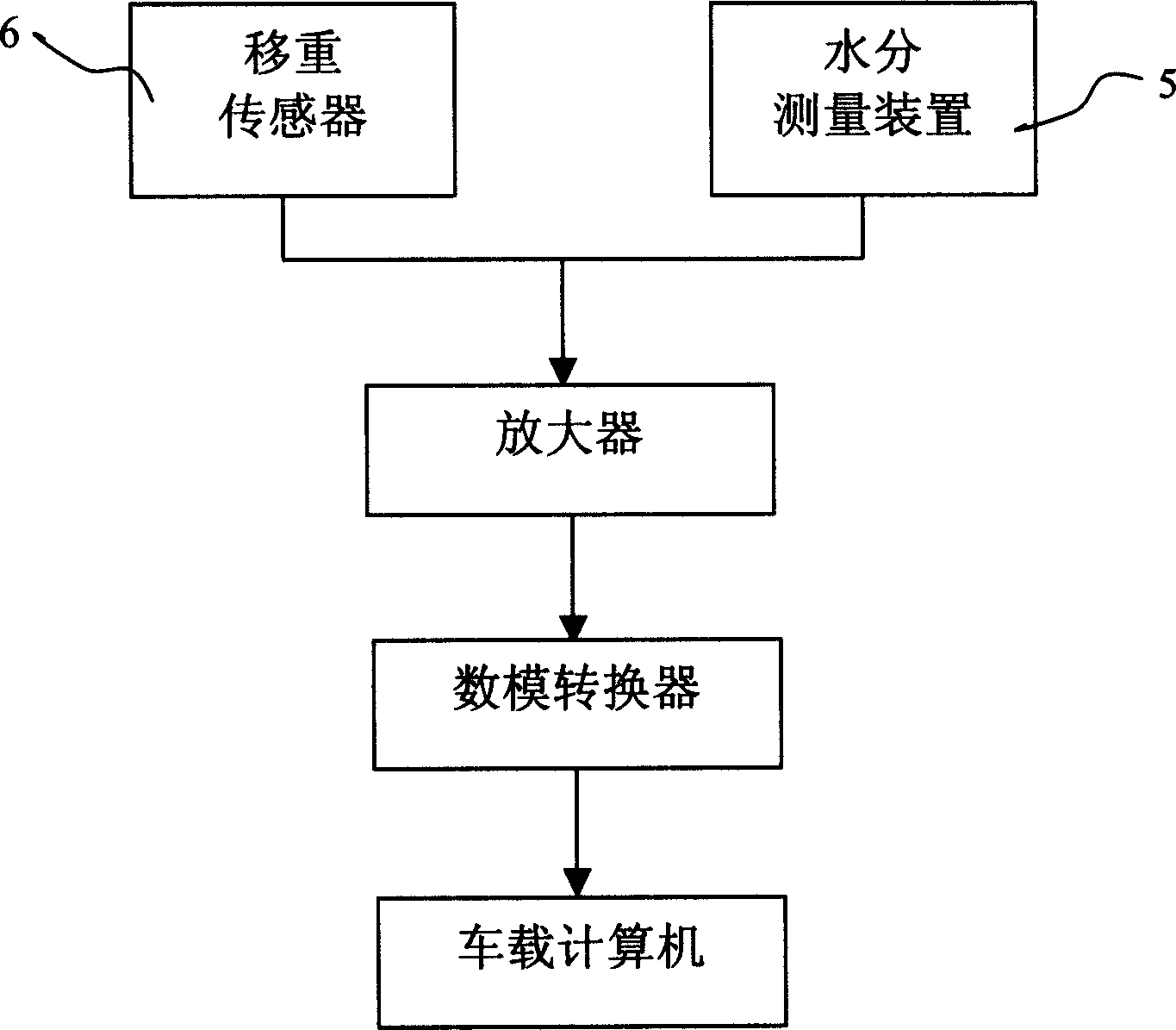

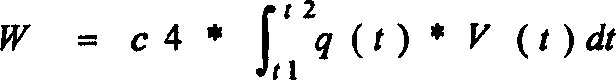

[0026] in figure 1 Among them, the output monitoring device of a combine harvester required by the present invention includes: a driving device 1, a coupling 2, a conveyor housing 3, a screw pusher, a moisture measuring device 5, a load cell 6, a frame 7, Damping platform 8. The driving device 1 is connected to the screw pusher 4 through the coupling 2 to drive the screw pusher 4. Under the action of the auger 4, the material to be measured is drawn between the auger 4 and the conveyor housing 3. figure 1 Movement in the horizontal direction as shown in. During the movement of the material, the moisture content of the material is measured by the moisture measuring device 5 installed on the lower side of the conveyor shell 3. The weighing sensor 6 installed between the conveyor housing 3 and the shock-absorbing platform 8 is responsible for measuring the gravity signal of the material and feeding the signal back to the on-board computer. The on-board computer integrates the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com